Feb 2 2021

In the field of Chemistry, the 2020 Nobel Prize was awarded to researchers who designed lithium-ion rechargeable batteries. These batteries have turned out to be an important energy source for electronic devices varying from small IT devices to electric vehicles.

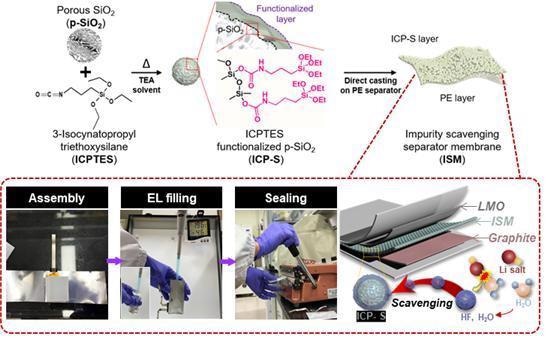

Battery production in ambient air using a multi-functional separator. Image Credit: Pohang University of Science and Technology.

Battery production in ambient air using a multi-functional separator. Image Credit: Pohang University of Science and Technology.

Tesla, a leading automaker in the United States, recently stressed the necessity to set up a novel production system and decrease the cost of the battery. The battery cost accounts for a huge portion of electric vehicles and reduction in cost is essential to make them attractive.

A collaborative research group, under the guidance of Professor Soojin Park and PhD candidate Hye Bin Son of Pohang University of Science and Technology’s (POSTECH) Department of Chemistry along with Professor Seungmin Yoo of Ulsan College, has been successful in designing a multi-functional separator which enables the batteries to work even when the pouch cell is formed in ambient air.

The results of the study were reported in the latest online edition of the Energy Storage Materials journal.

As the electrolyte present within the battery reacts with moisture and results in degradation, lithium-ion batteries are normally formed in a dry room, maintained with humidity levels below 1%. But it is quite expensive to maintain a dry room.

To find a solution to this problem, studies have been performed to inhibit impurities like moisture or hydrofluoric acid by injecting additives into the electrolytes. However, these can result in undesirable side reactions during the operation of the battery.

While batteries run at a high temperature (50°C or higher), even slight moisture leads to rapid deterioration in performance. Hence, a material with the ability to trap impurities and moisture in the battery without any detrimental electrochemical reactions to the additives is highly sought after.

For this purpose, the collaborative research team added functional materials with the ability to trap impurities on the surface of the separator to raise the thermal stability and enhance battery performance.

This multi-functional separator showed outstanding heat resistance (shrinkage less than 10% following 30 minutes of storage at 140°C, while the traditional separator exhibited a shrinkage of 50%) and further exhibited enhanced electrochemical performance at the high temperature of 55°C (79% of the initial capacity retained after 100 charging cycles).

The team verified the efficiency of the functional material present in the electrolyte in the impurity-filled surrounding. The silane compound on the surface of the synthesized functional ceramic captures moisture and retains the ceramic structure well, but the usual ceramic material was degraded by the acidified electrolyte.

With the help of this study, the research team verified that this multi-functional separator assembled in the ambient air this time shows excellent lifespan compared to the traditional separators, which confirms that it offers stable performance much more than a normal separator.

This newly developed multi-functional separator shows great stability and excellent electrochemical performance at high energy density. With this first successful case of fabricating batteries in ambient air, it is expected to play a big role in reducing battery cost.

Soojin Park, Professor, Pohang University of Science and Technology

Park has been studying battery separators for a long time via several methods.

This study was performed with the support from the National Research Foundation of Korea grant, which was financially supported by the Korean government (2020 M2D8A2093081, 2018R1C1B6004908).

Journal Reference:

Son, H. B., et al. (2021) A Dry Room-Free High-Energy Density Lithium-ion Batteries Enabled by Impurity Scavenging Separator Membrane. Energy Storage Materials. doi.org/10.1016/j.ensm.2021.01.018.