Mar 1 2021

Scientists from Tokyo Metropolitan University have unraveled how liquid foams collapse by visualizing individual collapse “events” using high-speed video microscopy.

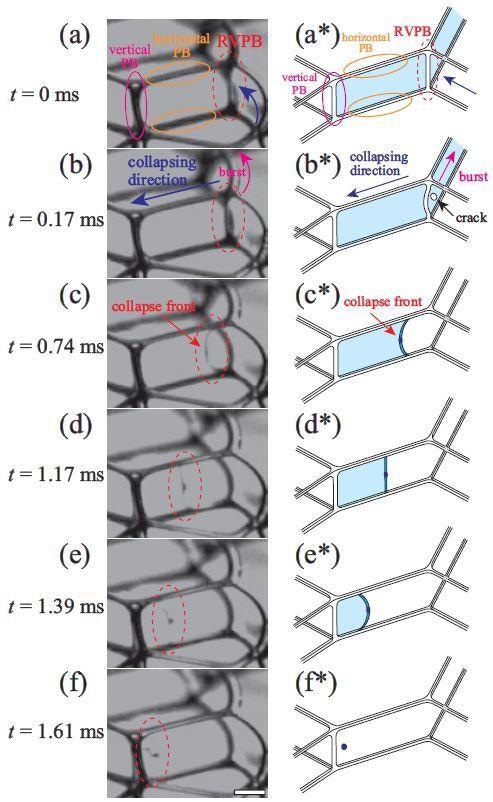

An initial crack in a film creates a RVPB (a). A second crack event in the film (b) causes a “collapse front” to be formed which sweeps up the RVPB (c) before its shape begins to flatten (d) and invert (e), finally leaving a droplet (f). Image Credit: Tokyo Metropolitan University

An initial crack in a film creates a RVPB (a). A second crack event in the film (b) causes a “collapse front” to be formed which sweeps up the RVPB (c) before its shape begins to flatten (d) and invert (e), finally leaving a droplet (f). Image Credit: Tokyo Metropolitan University

They discovered that cracks in films resulted in a decreasing liquid front, which sweeps up the original border of the film, reverses its shape, and discharges a droplet that strikes and breaks other films. The observations and physical model of the researchers offer a better understanding of how to create foams less or more resistant to collapse.

Gaining better insights into how foams collapse is a crucial business. Whether it is to guarantee that fire extinguishing foams last longer to put out flames, cleaning up hazardous foams in rivers and seas, or just achieving the perfect rise on a cake, knowing how foam materials drop is crucial to customizing their properties, both to make foams last longer or make them disappear faster.

A research team under the guidance of Professor Rei Kurita from Tokyo Metropolitan University has been performing high-speed video microscopy experiments on liquid foams.

By producing foams interspersed between two thin and transparent plates, they have a direct view of an entire range of complex phenomena that take place when they start to collapse. In an earlier study, they demonstrated that the main way by which foams collapse is through the droplets production when separate films get ruptured.

Such droplets fly out at high speeds and disintegrate other surrounding films, resulting in a cascade of breakages that make the foam crumble. Moreover, it was still not known how the droplets were formed. Most significantly, it was not evident when the droplets developed, and when they did not.

Currently, researchers have started to untangle the complex mechanism behind the formation of such droplets. When a first crack develops in a film, the film subsides and discharges a wobbling line of liquid where the original film border was, called the Released Vertical Plateau Border (RVPB).

When the RVPB wobbles, there is a collection of liquid at the core of the RVPB. When an additional crack develops in the leftover film, a subsiding line of liquid forms and sweeps up the RVPB. Fascinatingly, videos indicated that this front tends to reverse in shape as it moves.

The researchers discovered that this is mostly caused by an inertial effect, as the bulkier central part moves a bit less under a constant force. Crucially, this inversion eventually leads to the release of a droplet, starting a cascade of film breakage events.

Their study is contrary to earlier examination that analyzed standing separate films; the collection of liquid in the middle of RVPBs is possible within foams, where liquid can be provided by surrounding borders and films. The physical model developed by the researchers to explain the dynamics was demonstrated to provide reliable forecasts of front velocity and appropriate time scales.

Lastly, the team substituted laboratory reagents with a household detergent and repeated the experiment, thus making foam that is much more durable. When there is a bubble burst at the side, they spotted a similar collection of liquid in the center of RVPBs, though considerably less compared to before.

The improved elasticity of the film also indicated that it was highly implausible for two cracks to develop in the same film—this means no droplets were developed. That is, no cascaded bubble collapse: in light of the mechanism found above, this demonstrates finally that both less transport inside RVPBs and fewer cracks contributed directly to foam stability.

Such in-depth knowledge is crucial for directing the design of new foam materials with improved properties. The researchers are confident that their study might motivate the development of advanced insulation materials, food products, cosmetics, and detergents.

This study was financially supported by a JSPS Research Fellowship for Young Scientists (20J11840), and JSPS KAKENHI Grants-in-Aid for Scientific Research (17H02945, 20H01874, 20K14431).

Journal Reference:

Yanagisawa, N., et al. (2021) Dynamics and mechanism of liquid film collapse in a foam. Soft Matter. doi.org/10.1039/D0SM02153A.