Apr 6 2021

About three years ago, researchers from the University of Michigan had identified a new artificial photosynthesis device composed of silicon and gallium nitride (Si/GaN).

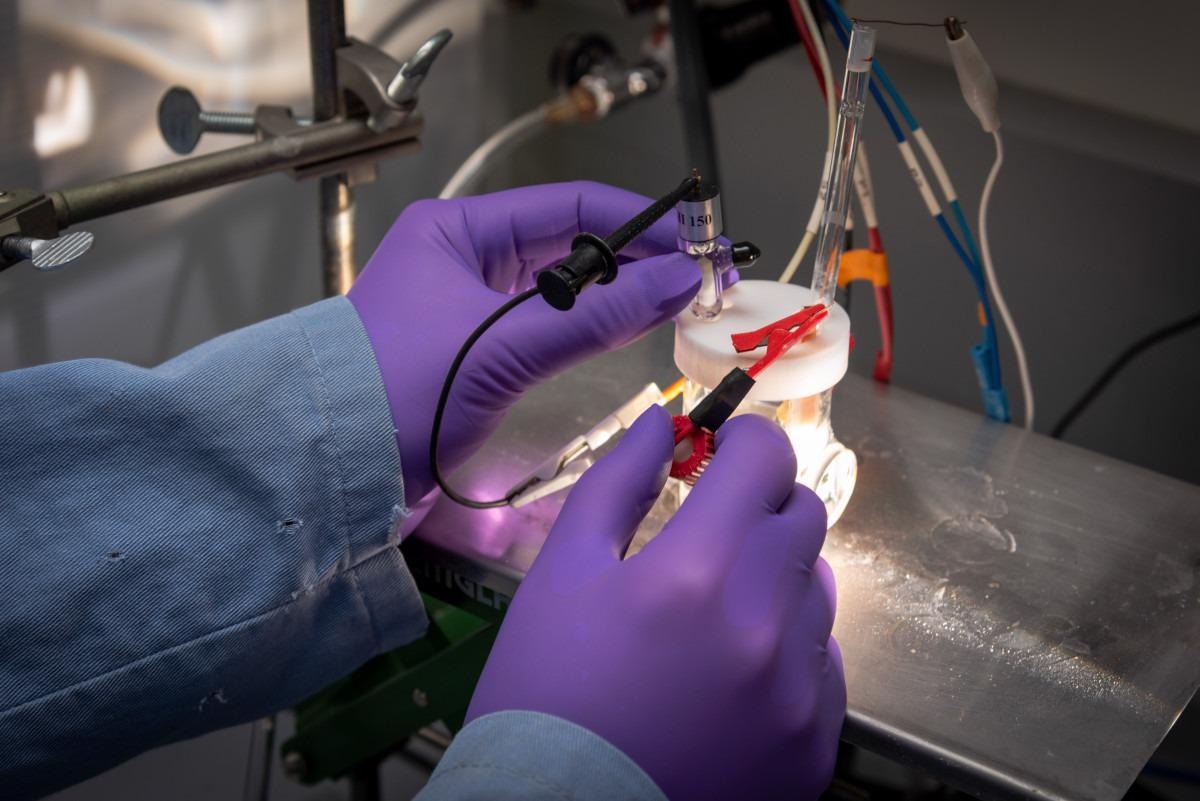

Guosong Zeng, a postdoctoral scholar in Berkeley Lab’s Chemical Sciences Division, at work testing an artificial photosynthesis device made of gallium nitride. Zeng, along with Berkeley Lab staff scientist Francesca Toma, discovered that the device improves with use. Image Credit: Thor Swift/Lawrence Berkeley National Laboratory.

Guosong Zeng, a postdoctoral scholar in Berkeley Lab’s Chemical Sciences Division, at work testing an artificial photosynthesis device made of gallium nitride. Zeng, along with Berkeley Lab staff scientist Francesca Toma, discovered that the device improves with use. Image Credit: Thor Swift/Lawrence Berkeley National Laboratory.

This device uses solar light to produce carbon-free hydrogen for fuel cells with double the stability and efficiency of some former technologies.

Now, in association with the University of Michigan and Lawrence Livermore National Laboratory (LLNL), investigators from the Lawrence Berkeley National Laboratory (Berkeley Lab) of the Department of Energy (DOE) have revealed an unexpected, self-enhancing characteristic in the Si/GaN material that contributes to its highly stable and efficient performance in transforming water and light into carbon-free hydrogen.

The researchers’ findings, published in the Nature Materials journal, can help radically speed up the commercialization of hydrogen fuel cells and artificial photosynthesis technologies.

“Our discovery is a real game-changer,” stated Francesca Toma, the senior author of the study and a staff scientist in the Chemical Sciences Division at the DOE’s Lawrence Berkeley National Laboratory (Berkeley Lab).

Materials in solar fuel systems will usually degrade, turn out to be less stable, and thus generate hydrogen in a less efficient manner.

“But we discovered an unusual property in Si/GaN that somehow enables it to become more efficient and stable. I’ve never seen such stability,” Toma added.

Earlier artificial photosynthesis materials are either long-lasting materials that lack light-absorption efficiency, or exceptional light absorbers that lack durability.

On the other hand, gallium nitride and silicon are cheap and abundant materials that are extensively utilized as semiconductors in day-to-day electronics, like solar cells and light-emitting diodes (LEDs), stated Zetian Mi, the co-author of the study and a professor of electrical and computer engineering from the University of Michigan.

Professor Mi had designed Si/GaN artificial photosynthesis devices 10 years ago.

When the Si/GaN device, developed by Professor Mi, achieved a record-breaking 3% solar-to-hydrogen efficiency, he speculated how these standard materials could perform exceptionally well in a unique artificial photosynthesis device. This made him seek Toma’s help.

HydroGEN: Taking a Team Science Approach to Solar Fuels

Professor Mi had learned about Toma’s expertise in sophisticated microscopy methods for probing the nanoscale (that is, billionths of a meter) characteristics of artificial photosynthesis materials via HydroGEN.

HydroGEN is a five-national laboratory consortium funded by the DOE’s Hydrogen and Fuel Cell Technologies Office and headed by the National Renewable Energy Laboratory to promote collaborations between industry, academia and National Labs for the development of next-generation water-splitting materials.

These interactions of supporting industry and academia on advanced water-splitting materials with the capabilities of the National Labs are precisely why HydroGEN was formed—so that we can move the needle on clean hydrogen production technology.

Adam Weber, Co-Deputy Director of HydroGEN

Weber is also the Hydrogen and Fuel Cell Technologies Lab Program Manager at Berkeley Lab.

Toma and Guosong Zeng, the study lead author and a postdoctoral scholar in Berkeley Lab’s Chemical Sciences Division, believed that GaN could play a key role in the unique potential of the device with regard to the stability and efficiency of hydrogen production.

To find this out, Zeng performed a photoconductive atomic force microscopy experiment at Toma’s laboratory to determine how GaN photocathodes can efficiently transform the absorbed photons into electrons, and can subsequently recruit those free electrons to convert water into hydrogen, before the material begins to decompose and turns out to be less efficient and stable.

The researchers expected to observe a steep drop in the photon absorption stability and efficiency of the material after only a few hours.

To their amazement, they noted a two-three orders of magnitude enhancement in the photocurrent of the material. This photocurrent was emerging from small facets along the 'sidewall' of the GaN grain, added Zeng.

What was more confounding was that the efficiency of the material had increased over time, although the overall material surface did not change considerably, added Zeng.

“In other words, instead of getting worse, the material got better,” Zeng further added.

The team collected more clues by using angle-dependent X-ray photon spectroscopy (XPS), as well as scanning transmission electron microscopy (STEM) installed at the National Center for Electron Microscopy in Berkeley Lab’s Molecular Foundry.

These experiments demonstrated that a 1-nm layer combined with oxygen, gallium and nitrogen—or gallium oxynitride—had developed along some of the sidewalls.

A chemical reaction had occurred, adding “active catalytic sites for hydrogen production reactions,” informed Toma.

The study co-authors Tadashi Ogitsu and Tuan Anh Pham from LLNL performed density functional theory (DFT) simulations that validated their observations.

By calculating the change of distribution of chemical species at specific parts of the material’s surface, we successfully found a surface structure that correlates with the development of gallium oxynitride as a hydrogen evolution reaction site.

Tadashi Ogitsu, Study Co-Author, Lawrence Livermore National Laboratory

Ogitsu continued, “We hope that our findings and approach—a tightly integrated theory-experiments collaboration enabled by the HydroGEN consortium—will be used to further improve the renewable hydrogen production technologies.”

We’ve been working on this material for over 10 years—we know it’s stable and efficient. But this collaboration helped to identify the fundamental mechanisms behind why it gets more robust and efficient instead of degrading. The findings from this work will help us build more efficient artificial photosynthesis devices at a lower cost.

Zetian Mi, Study Co-Author and Professor of Electrical and Computer Engineering, University of Michigan

Looking ahead, Toma and her research team would prefer to test the Si/GaN photocathode in a water-splitting photoelectrochemical water-splitting photoelectrochemical cell.

They added that Zeng will test analogous materials to gain a deeper understanding of how nitrides play a role in the stability of artificial photosynthesis devices, which is something they never believed would be feasible.

“It was totally surprising. t didn’t make sense—but Pham’s DFT calculations gave us the explanation we needed to validate our observations. Our findings will help us design even better artificial photosynthesis devices,” added Zeng.

“This was an unprecedented network of collaboration between National Labs and a research university. The HydroGEN consortium brought us together—our work demonstrates how the National Labs’ Team Science approach can help solve big problems that affect the entire world,” concluded Toma.

The co-authors of the study include Guiji Liu, Jason Cooper, and Chengyu Song from Berkeley Lab, and Srinivas Vanka from the University of Michigan. The Molecular Foundry is a DOE Office of Science user facility at Berkeley Lab.

The study was funded by the HydroGEN Advanced Water Splitting Materials Consortium, established as part of the Energy Materials Network under the Office of Energy Efficiency and Renewable Energy of the DOE.

Journal Reference:

Zeng, G., et al. (2021) Development of a photoelectrochemically self-improving Si/GaN photocathode for efficient and durable H2 production. Nature Materials. doi.org/10.1038/s41563-021-00965-w.