Apr 12 2021

An international research group working at the Lawrence Berkeley National Laboratory (Berkeley Lab) of the U.S. Department of Energy (DOE) has gained a better understanding of lithium-rich battery materials with the help of a special X-ray instrument.

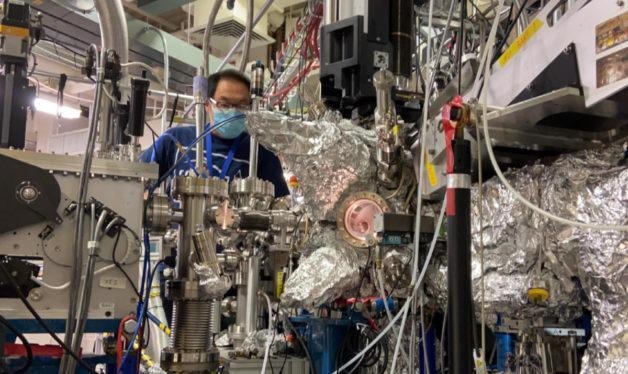

Wanli Yang, a senior scientist at Berkeley Lab’s Advanced Light Source, working on a resonant inelastic X-ray scattering (RIXS) system. Yang adapted the RIXS technique for a recent Joule study on lithium-rich battery materials. Image Credit: Wanli Yang/Berkeley National Laboratory.

Wanli Yang, a senior scientist at Berkeley Lab’s Advanced Light Source, working on a resonant inelastic X-ray scattering (RIXS) system. Yang adapted the RIXS technique for a recent Joule study on lithium-rich battery materials. Image Credit: Wanli Yang/Berkeley National Laboratory.

Such materials have been the subject of intense studies for their ability to expand the operation of electronic devices and the range of electric vehicles.

The team targeted their analyses on a material known as lithium manganese oxide (Li2MnO3), the extreme case of the supposed 'lithium-rich' materials, comprising the biggest possible amount of lithium within this range of materials.

A newly designed principle of the battery community is that battery electrodes made up of lithium-rich materials may enable high capacity, high voltage operation because the oxygen present in the material takes part in reversible chemical 'redox' reactions, wherein atoms of oxygen cyclically gain and lose electrons.

This allows the battery to have a greater capacity to preserve and utilize electrical charge.

But this study has demonstrated that the reversible reactions actually do not involve oxygen in Li2MnO3 at the time of battery operation.

Rather, an additional study conducted on manganese—the other element in the material—showed that the reason behind the potential cycling of the material can be attributed to an extraordinary but complete change to manganese-based reactions, with a comparatively low capacity, soon after the initial charging.

This discovery provides new opportunities to investigate high energy electrode materials beyond the lithium-rich family.

Besides this, the researchers were particularly amazed to find a 'partially reversible' disappearance and formation of carbonate compounds on the material surface.

Such highly reactive surface characteristics indicate that the material can work as a catalyst and could enable the reversible chemical reactions needed for unusual, advanced batteries, such as lithium-carbon dioxide and lithium-air batteries.

The carbonate compounds noticed on the Li2MnO3 surface contain carbon attached to oxygen atoms, which means lithium-rich materials may be effective catalysts for reactions that involve carbon dioxide gas.

What we all feel is exciting is that, through a fundamental spectroscopic study of this material, we not only clarified the reaction mechanism of this long-debated material, but also found a conceptually different use of it as a catalyst.

Wanli Yang, Senior Scientist, Advanced Light Source, Berkeley National Laboratory.

Yang has also adapted a method known as resonant inelastic X-ray scattering (RIXS) for this kind of battery analysis. He even served as the co-author of the study, working as part of a massive global collaboration. The new study was published in the Joule journal on March 4th, 2021.

Some findings indicated that this material is actually more suitable as a catalyst due to its highly reactive surface. So our battery material collaborators tested it as a catalyst and found it indeed has superior performance for lithium-carbon dioxide and lithium-air batteries.

Wanli Yang, Senior Scientist, Advanced Light Source, Berkeley National Laboratory

The team observed in this analysis that the high-capacity carbonate cycling built on the Li2MnO3 catalyst has a much better reversibility when compared to analogous systems with standard oxide-based catalysts.

These outcomes also pave the way to use a whole range of alkali-rich materials as catalysts for other kinds of applications, including fuel cells.

A dedicated beamline at the Advanced Light Source was integral to the study. This beamline can fundamentally dissect chemical reactions a single element at a time to determine which ones do, or do not, contribute to reactions.

The Advanced Light Source is a synchrotron that can create light in a range of wavelengths or 'colors,' from infrared to X-rays.

RIXS was used by the researchers to plot the sample chemistry at different phases in the charge-discharge cycle. But they did not find any proof of the reversible oxygen redox reactions predicted for this kind of material by several investigators.

Rather, the researchers found that oxygen is involved in just a one-way oxidation reaction, and in highly active surface reactions.

Yang observed that the latest analysis overturns many well-known models for interpreting the oxygen redox activities in battery electrodes.

However, it does pave the way to new thinking about the kinds of cost-effective materials that can use oxygen redox reactions, because the behavior of the oxygen redox reaction within lithium-rich electrodes was found to be the same as that of traditional electrodes being used today.

Exploiting the oxygen redox reaction could lead to batteries with high-capacity, high-voltage performance.

The study also involved other researchers from the Berkeley National Laboratory, SLAC National Accelerator Laboratory, Stanford University, Peking University Shenzhen Graduate School, Tianjin Normal University, Northeastern University, and the Chinese Academy of Sciences in China.

The study was funded by the U.S. DOE Office of Science, the U.S. DOE Data, Artificial Intelligence, and Machine Learning at DOE Scientific User Facilities project, the National Key R&D Program of China, Beijing Municipal Science & Technology Commission, and the National Natural Science Foundation of China.

The study, conducted at Stanford University, was also funded by the U.S. DOE Office of Basic Energy Sciences, Division of Materials Sciences and Engineering. The Advanced Light Source is a DOE Office of Science user facility at the Berkeley Laboratory.

Journal Reference:

Zhuo, Z., et al. (2021) Cycling mechanism of Li2MnO3: Li–CO2 batteries and commonality on oxygen redox in cathode materials. Joule. doi.org/10.1016/j.joule.2021.02.004.