Jun 18 2021

Recently, green hydrogen has attracted a great deal of attention since it is a source of clean energy and promotes carbon neutrality. It can be generated without using fossil fuels.

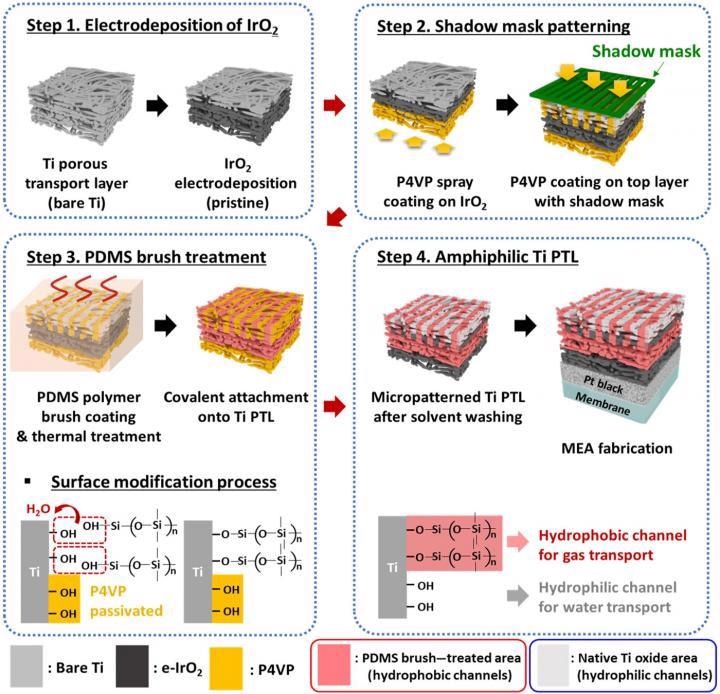

Schematic fabrication procedure of the amphiphilic Ti PTLs. Image Credit: Korea Institute of Science and Technology (KIST).

Schematic fabrication procedure of the amphiphilic Ti PTLs. Image Credit: Korea Institute of Science and Technology (KIST).

Researchers from Korea have successfully improved the efficiency of unitized regenerative fuel cells that can be utilized to effectively produce green hydrogen and generate electricity.

The unitized regenerative fuel cells have hydrogen production and fuel cell modes. They are cost-effective, eco-friendly and are independent power generation and energy storage devices that require less space for operation. The separate installation of fuel cells and electrolysis devices requires a larger amount of space.

While the amount of electricity produced from renewable energy sources, like wind power and sunlight, exceeds the amount of electricity in demand, the electrolysis cell mode is used to generate hydrogen to store energy. The fuel cell mode can be used to generate electricity when the electricity demand is higher.

The Korea Institute of Science and Technology (KIST) has announced that a research team, headed by Dr Hyun S. Park from the Center for Hydrogen Fuel Cell Research, Dr Jong Min Kim from the Materials Architecturing Research Center, and a research team headed by Professor Yung-Eun Sung from the Seoul National University, have teamed up to develop a component.

The component is based on a new concept to resolve the problems caused by the mixing of gas and water within a bifunctional device used for producing hydrogen and generating power — that is, the unitized regenerative fuel cell. This allows the efficient transport of gas and water, and considerably improves the round-trip efficiency and performance of the devices.

Efficient hydrogen production under conditions of the electrolysis cell mode requires water to reach the catalyst layer from the electrode within a short duration. The hydrogen and oxygen generated should thus be drained quickly. The generated oxygen and hydrogen must enter and the generated water must be drained as quickly as possible when the device functions in a mode opposite of the fuel cell.

The unitized device can work with the same efficiency as the fuel cells or the general electrolysis device, when the input materials are repeatedly allowed to cycle efficiently and hydrogen, oxygen and water are able to be drained out effectively.

Dr Hyun S. Park’s research team identified the reasons for the reduced efficiency of the unitized device under conditions of alternating fuel cell and electrolysis cell modes. The team linked these problems to the repeated input and drainage of gas and water that potentially caused the residual water and gas to remain trapped within the device.

To address this problem, the researchers speculated the need for a hydrophilic electrode to ease the transportation of water and a hydrophobic electrode to efficiently conduct gas-phase reactions. The electrode’s surface was first treated to have hydrophilic properties and then coated with a micropatterned plastic layer to create an electrode that could exhibit both hydrophobic and hydrophilic properties.

The smooth transportation of gas and water was achieved along with an 18-fold increase in the drainage rate of gas (selective drainage from the surface of the fabricated electrode). When the newly designed component was used to fabricate the unitized device, a four-fold increase in performance was achieved under conditions of the fuel cell mode.

The efficiency of hydrogen production achieved through this technique is twice the efficiency of hydrogen produced through the traditional component. The stability of the enhanced performance (concerning hydrogen production and power generation) was confirmed over 160 hours.

This is the first time that amphiphilic electrodes exhibiting stable and high performance under conditions of both fuel cell power generation mode and electrolysis green hydrogen production mode have been used for the fabrication of unitized regenerative fuel cells.

Dr Hyun S. Park, Center for Hydrogen, Fuel Cell Research, Korea Institute of Science and Technology

“It is expected that the developed device can also be used for the fabrication of various other devices such as electrochemical carbon dioxide reduction and nitrogen reduction devices, where both gas and liquid enter the devices simultaneously,” Dr. Park concluded.

Journal Reference:

Lim, A., et al. (2021) Amphiphilic Ti porous transport layer for highly effective PEM unitized regenerative fuel cells. Science Advances. doi.org/10.1126/sciadv.abf7866.