The accumulation of greenhouse gases, such as carbon dioxide (CO2), in the atmosphere contributes to climate change. Therefore, capturing and recycling CO2 are crucial for reducing detrimental environmental effects and to deal with the climate crisis.

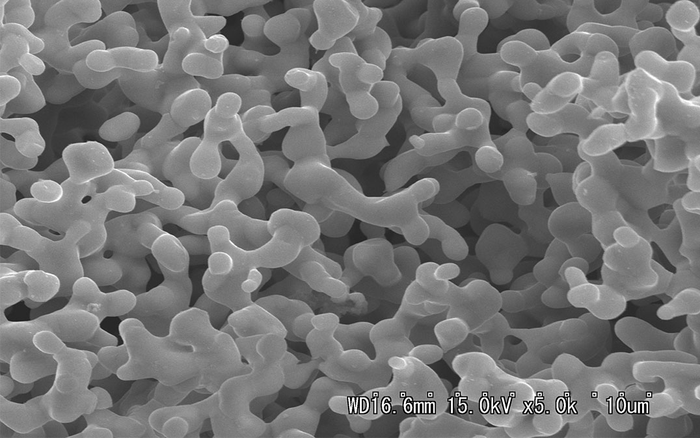

Image Credit: University of Tsukuba.

Japanese scientists created a polymer-coated metal catalyst that speeds up CO2 conversion and provides green energy insights.

Scientists from the University of Tsukuba showed how porous tin (Sn) catalysts coated with polyethylene glycol (PEG) polymer promote CO2 transformation into a useful carbon-based fuel. The research has been published in the ACS Catalysis journal.

Different polymers can capture CO2 molecules, and Sn catalysts are recognized for reducing CO2 to other molecules, such as formate (HCOO−), which can be reused to power fuel cells.

We were interested in combining these capabilities into a single catalytic system that could scrub CO2 from its surroundings and recycle it into formate. However, it’s difficult to obtain only the desired product, formate, at a high production rate and in high yield, so we had to fine-tune the catalyst design.

Yoshikazu Ito, Professor and Research Group Leader, University of Tsukuba

The production rate of formate by PEG-coated Sn was found to be 24 times higher when compared to conventional Sn plate electrodes, and no byproducts were identified (>99% yield of formate). To gain in-depth knowledge on this enhanced CO2-reduction reaction, the scientists created an Sn catalyst coated with another CO2-capturing polymer (polyethyleneimine; PEI) whose structure interacts variably with incoming CO2.

The PEG-coated Sn still outclassed the PEI-coated Sn, and the researchers took the chemical characteristics of these polymers into account and remarked that PEI held the CO2 molecules too tightly. On the contrary, PEG struck a key balance in capturing and then releasing CO2 to the catalytic Sn core.

Modeling this reaction using theoretical computations confirmed the favorability of PEG shuttling CO2 to the Sn center and explained the accelerated formate production. However, we wanted to further clarify the PEG-CO2 interactions.

Samuel Jeong, PhD Student, University of Tsukuba

Further comprehensive computations showed that the absence of polymer restricts the Sn catalyst’s ability to capture CO2 and that an excessively dense layer of PEG inhibits the transfer of CO2 to the metal surface, which decreases formate production. Hence, a complete but relatively minimal layer of PEG is ideal for funneling CO2 to Sn, while maintaining a CO2-rich environment and prohibiting byproduct release.

The mantra “reduce, reuse, recycle” does not refer to single-use plastics any longer. The simple catalyst-coating technique indicated by Ito and colleagues can be employed to create systems that effectively recycle CO2 into beneficial compounds, such as formate, which can power fuel cell devices that offer green electricity.

Journal Reference:

Jeong, S., et al. (2021) Polyethylene Glycol Covered Sn Catalysts Accelerate the Formation Rate of Formate by Carbon Dioxide Reduction. ACS Catalysis. doi.org/10.1021/acscatal.1c02646.