Recent advances in intelligent textiles, device miniaturization and the advent of the Internet of Things (IoT) have led to an increase in demand for innovative means of incorporating electrical features into textile-based materials such as conductive fibers, fabrics, yarns, and even finished goods.

Study: Progress in Flexible Electronic Textile for Heating Application: A Critical Review. Image Credit: yanin kongurai/Shutterstock.com

A recent study presented in a special 'Nanotechnologies in Textiles' issue of the Materials journal offered useful insights into this exciting, ever-evolving area and detailed some of the possibilities, balances, and challenges offered via the current wave of smart textiles.

Most notably, the study looked at the assembly processes involved in smart textiles' manufacture, investigating the need to strike a careful balance between product ergonomics, versatility, integration potential, heating properties and energy efficiency. It also sheds considerable light on the importance of conductive fibers to these devices.

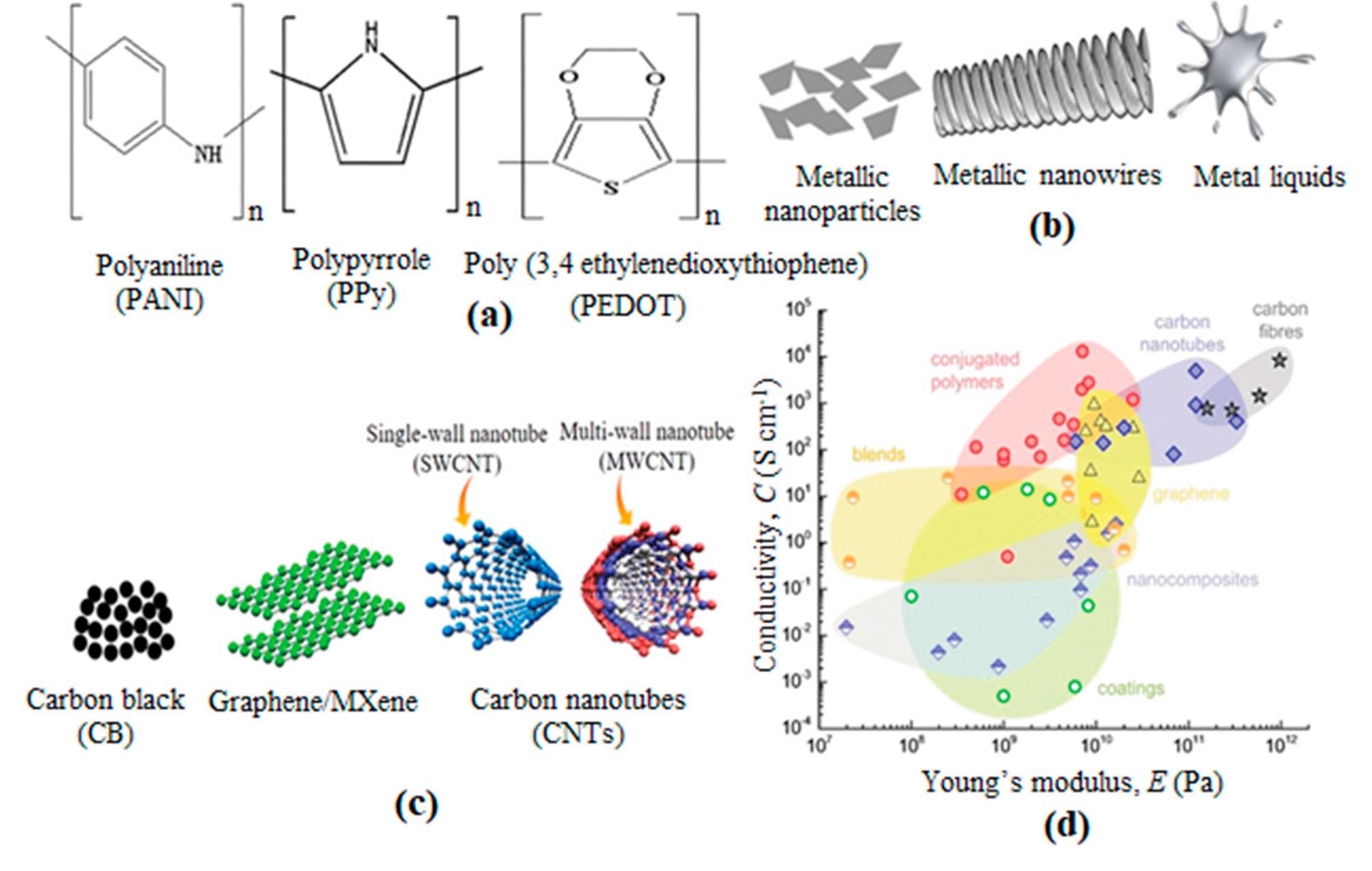

(a) Polymeric, (b) metallic, and (c) carbon-based electroactive materials for e-textiles. (d) Electrical conductivity vs. Young's modulus of different electroactive fibers based on CNTs (blue diamonds), carbon fibers (gray stars), ICPs (red circles), blends of conjugated and insulating polymers (orange/white circles), graphene (yellow triangles), nanocomposites of CB (blue/white diamonds), CNTs or graphene embedded in an insulating polymer matrix and (green/white circles) coatings of textile fibers with ICPs, CNTs, or graphene. Image Credit: Repon, Md. R et al., Materials

Textiles offer excellent potential for flexible electronic devices. These typically offer exceptional deformability, robust moisture resistance, and a general soft feel and level of comfort that makes them appealing options for consumers looking for comfortable, aesthetically pleasing wearable technologies.

The key concept behind electronic textiles (e-textiles) is that this type of device is able to provide useful information to facilitate an appropriate response.

For example, an e-textile could be able to sense and respond to specific thermal, mechanical, chemical, electrical, magnetic, or optical stimuli and prompt some sort of action in response, potentially heating a garment or adjusting its properties.

Existing types of smart textiles are typically classified into three generations. The first generation—passive e-textiles—features sensors able to track or stimulate environmental changes; the second generation—active e-textiles—features textiles containing sensors and actuators able to detect and actuate a part of their environment. The third generation—sophisticated e-textiles—can feel and appropriately respond to external stimuli.

Central to the usefulness and applicability of all these generations of smart textiles is an array of conductive fibers, yarns, fabrics, and textiles. These electrically conductive threads are often designed to incorporate specifically conductive materials such as metal wires, metallic yarns, or even conductive polymers.

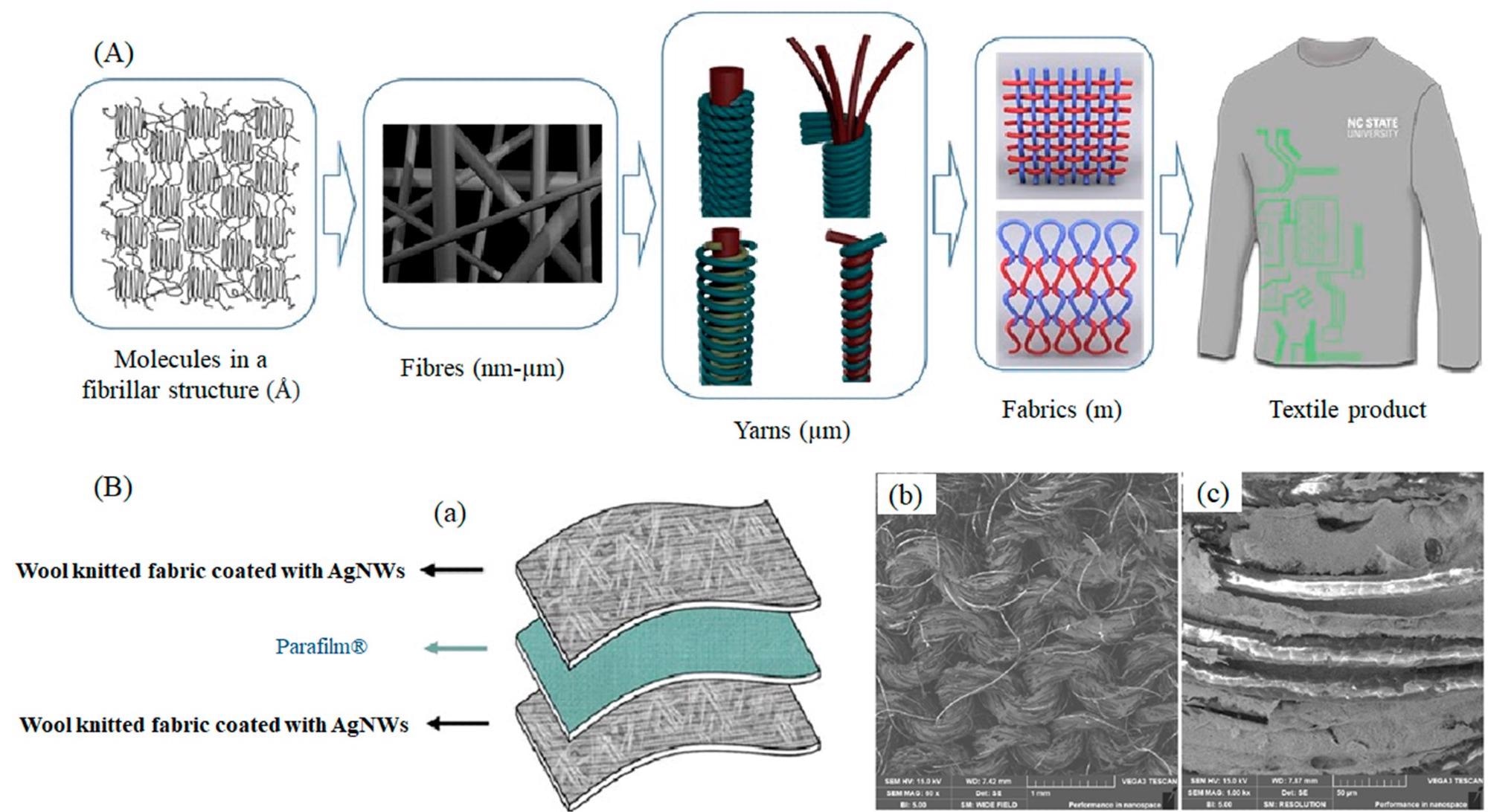

(A). Electrically conductive coatings for fibre-based e-textiles; (B). (a) Silver nanowire coated knitted wool fabrics for wearable electronic applications, SEM images of conductive knitting fabric after coating and washing with distilled water under (b) 60x and (c) 1000x magnifications. Image Credit: Repon, Md. R et al., Materials

The properties of these versatile conductive fibers essentially provide the foundation of smart textiles' functionality. Using advanced manufacturing methods, it has been possible to produce conductive fibers in staple or filament lengths, integrating these with conventional fibers and adding functionality to wearables and garments without impacting flexibility or wearer comfort.

Typical production methods have thus far included electroless plating, sputtering, evaporative deposition, and conductive polymer coating. New developments are ongoing, however, particularly looking at the development of conductive textiles by printing patterns on fabrics with conductive ink.

The authors of the research anticipate a boom in the production of smart textiles and their applications in the coming years, driven in part by ongoing advances in the fields of textiles, electronics, materials, polymers, and information technology.

The potential application areas for conductive materials are vast, including advanced wearable health and fitness monitoring devices, smart protective clothing able to intelligently respond to external risks such as heat or moisture, and intelligent fashion able to help dynamically manage user comfort.

![(A). I–V curve and (b) Joule heating performances of silicone-coated M-textile. (c) Time–temperature curve at a at a constant voltage of 3 V for silicone-coated M-textile. (d) Temperature stability of the silicone-coated M-textile in heating/cooling cycles [109]; (B). SEM images of CBPFs and GCBPFs ((a,b) CNC-coated bamboo pulp fabric; (c,d) G/CNC-coated fabric with lowest thermal conductivity; (e,f) G/CNC-coated fabric with highest thermal conductivity).](https://d12oja0ew7x0i8.cloudfront.net/images/news/ImageForNews_57160_16358558938856907.jpg)

(A). I–V curve and (b) Joule heating performances of silicone-coated M-textile. (c) Time–temperature curve at a at a constant voltage of 3 V for silicone-coated M-textile. (d) Temperature stability of the silicone-coated M-textile in heating/cooling cycles; (B). SEM images of CBPFs and GCBPFs ((a,b) CNC-coated bamboo pulp fabric; (c,d) G/CNC-coated fabric with lowest thermal conductivity; (e,f) G/CNC-coated fabric with highest thermal conductivity). Image Credit: Repon, Md. R et al., Materials

From heat pads used for pain management through to the reduction of inflammation in joint injuries, the application of heated materials and textiles has a long history of use in therapeutic applications. To this end, one significant development highlighted by the authors lies in the area of carbon-based heating textiles and textile-based heaters, which employ Joule's law to generate heat by passing an electrical current through a material.

Conductive, carbon-based materials have long been regarded as a useful source of heat generation, and work is ongoing into the development of conductive heating textiles.

Conductive materials based on carbon are a good source of heat generation, with previous studies highlighting the potential of carbon nanotubes, graphene, and graphite powder being attached to fiber surfaces to make these conductive.

While there is certainly work to be done and additional studies to be undertaken—not least in ensuring that smart textiles maintain their conductive properties after repeated use, washing, and exposure to harsh environmental conditions—the field of smart textiles based on conductive fibers shows great promise.

It is only a matter of time before these innovative, flexible, and highly beneficial materials are entered into large-scale production and available on a commercial basis.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Repon, Md. R., and Daiva Mikučionienė. 2021. "Progress in Flexible Electronic Textile for Heating Application: A Critical Review" Materials 14, no. 21: 6540. https://www.mdpi.com/1996-1944/14/21/6540