Porous functional graded ceramics (porous FGCs) have enormous promise for overcoming the limited mechanical capabilities of uniformly highly permeable bioceramics utilized as bone transplants according to the latest study in the journal Ceramics.

Study: Porous Functional Graded Bioceramics with Integrated Interface Textures. Image Credit: SGr/Shutterstock.com

Introduction to Bio-Ceramics

Bio-ceramics are a type of synthetic polymers made up of biodegradable ceramic material and bio-glasses, with calcium phosphate and alumina, and several others being among the famous ones. For many years, bio-ceramics have been employed effectively within the human body.

They are often employed in surgical treatment and dentistry, although they may be suited for a variety of critical purposes such as hip replacements and extended usage as coatings. The substances in this category are typically tougher in composition, although relying on the use, they might be tightly packed or highly porous.

Porous Bio-Ceramics

Porous bio-ceramics have been widely researched to meet the growing need for bone replacement materials caused by demographic shifts. Perforated ceramics' qualities are heavily impacted by the characteristics of their micropores, which are defined by the overall permeability, diameter, geometry, interconnection, and dispersion of the openings.

The targeted modulation of the pore distribution over the whole specimen, for example, by developing extremely asymmetrical uni-directional directed pore structures, offers the most promise for reaching superior tensile qualities.

Porous ceramic FGCs have recently received interest as next-generation bio-materials to address the mechanical disadvantages of homogenous porous ceramics by integrating the benefits of closely packed and permeable ceramics in a homogeneous substance.

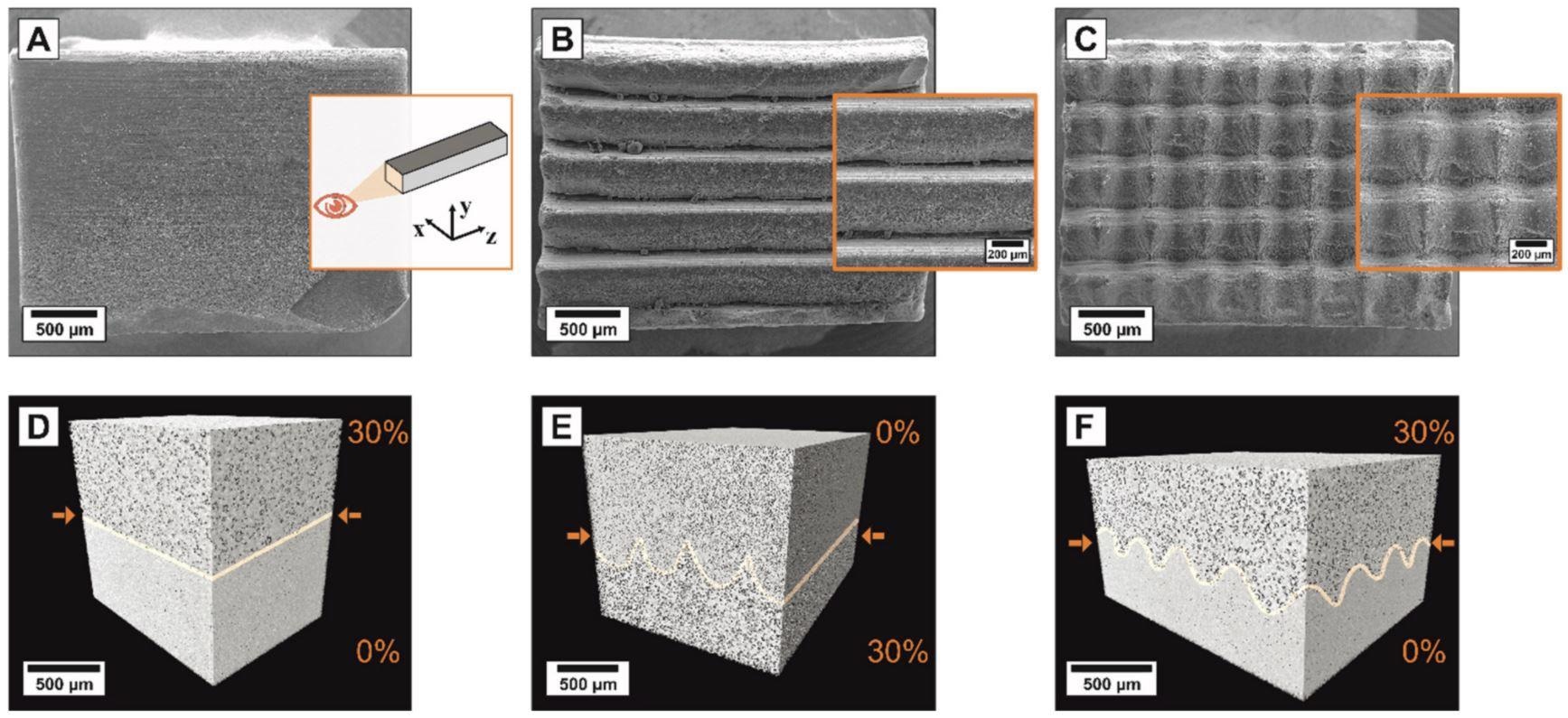

The SEM-micrographs (A–C) show the microstructure and ideal realizable morphologies of the individual interface texturings (non-textured, planar reference (A); 2D-linear waves (B); 3D-Gaussian hills (C) serving as an optical reference to the reconstructed µCT-images (C–F). The µCT-images visualize the real 3D-microstructure and morphology of the interface texturings for a porosity pairing with 0 and 30 Vol% of pore formers. To highlight the morphological differences between the three texture types, each interface was colored using semi-transparent lines. Image Credit: Biggemann, J. et al., Ceramics

Graded porosities have been frequently created by altering conventional fabrication procedures for homogenous porous ceramics, such as reactive templating, direct foaming, freeze casting, and so on.

Limitations of Bio-Ceramics

The low tensile qualities (brittleness, low tensile strength) of all calcium phosphate bio-ceramics manufactured in a porous form restrict their medical usage to non-major load-bearing sections of the skeleton. The modification mechanisms are being developed rapidly to enhance their mechanical properties.

Latest Findings

In the newest study, alumina (Al2O3) and hydroxyapatite (HAp) bioceramics with graded permeability and incorporated interfacial patterning were created using a two-step micro transfer-molding process supplemented with extra sacrificial pore formers.

Scanning electronic microscopy was used to analyze the HAp and Al2O3 interfaces crystal structures for the 3 texturing styles with varied porous couplings.

It was found that irrespective of the pore former concentration in each substrate, defect-free, the substance-to-substance coupling could be established over the whole specimen cross-section (4 mm 3 mm) for all porous combinations. The operating parameters (temperature, frequency) of the secondary casting phase are critical and must be experimentally tailored to the specimen shape to enable adequate bonding between the surfaces and prevent design delamination or crack development in the warmed first layer.

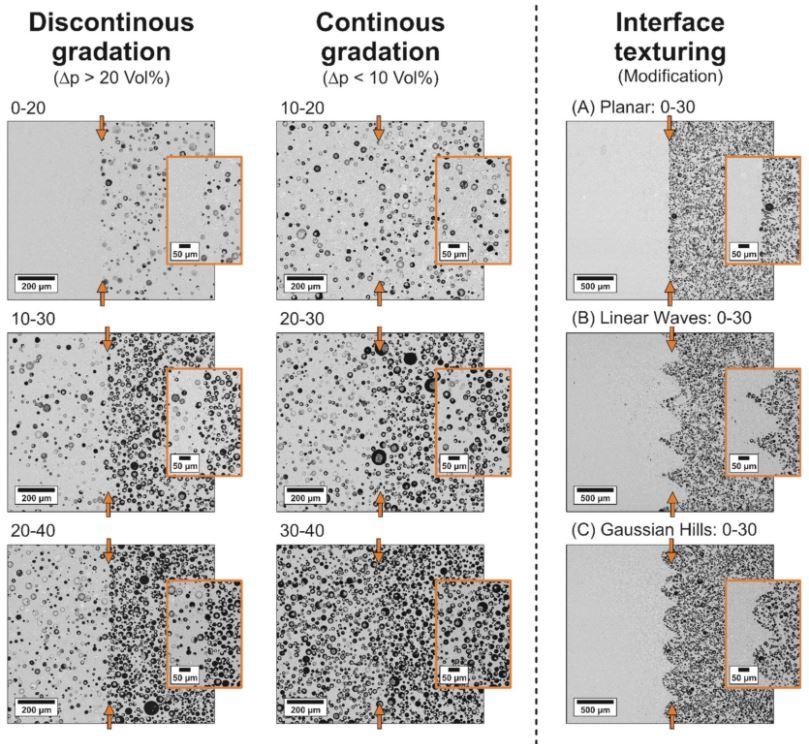

Microstructure of the porous functional graded Al2O3 ceramics (porous FGCs) with integrated interface-textures. The two-dimensional SEM cross-sections of the yz-plane show the interfaces (marked by the orange arrows and shown with larger magnification in the orange boxes) for various porosity pairings. The numbers above each image represent the amount of pore formers in each layer, the grey color of the SEM-micrographs corresponds to the ceramic matrix and the black color to the spherical pores. For porosity differences ∆p > 20 Vol% the gradient is discontinuous (left column), while for small porosity differences ∆p < 10 Vol% continuous gradients (middle column) can be obtained. The right column shows the three realized interface textures: planar non-textured reference (A), two-dimensional linear waves (B) and three-dimensional Gaussian hills (C). Image Credit: Biggemann, J. et al., Ceramics

When the permeability disparity was reduced to ∆p ≤ 10 Vol percent, the interface between the levels became unclear and consistent, resulting in gradient junctions.

Latest Findings on Mechanical Strength

For both homogeneous porous Al2O3 and HAp, Elastic modulus and flexural modulus decreased exponentially with the increase in porosity.

Young's moduli and flexural strengths were smaller in porous FGCs with a 0/30 Vol percent permeability connection than inhomogeneous porous samples with the same porosity.

The mechanical deformation did not form on the surface for any of the porous FGC specimen series, but rather in the porous 30 Vol percent layer between the inner support spans of the 4-point bending configuration.

The flexural strength of porous 0/30 Vol percent FGC samples was compared to homogenous porous samples with 30 Vol percent pore formers. No significant difference concerning the standard deviations could be monitored, and all FGCs series showed identical strength.

It was determined that changing the contact topologies has a huge ability to increase the wear resistance and impact resistance of porous FGCs in the presence of defects like cracks.

In short, Porous functional graded ceramics (porous FGCs) with incorporated connection patterns were created using an innovative two-step transfer-molding method that combined alumina (Al2O3) and hydroxyapatite (HAp) feedstocks with different amounts of globular pore precursors (0–40 Vol percent) to produce the well-defined porous structure. Defect-free, substance-to-substance bonding was possible for all porosity pairs, regardless of the pore former content used, exhibiting unrestricted combinability.

References

Biggemann, J. et al., 2021. Porous Functional Graded Bioceramics with Integrated Interface Textures. Ceramics MDPI, Volume 4(4), pp. 681-695. Available at: https://www.mdpi.com/2571-6131/4/4/48

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.