As far as industrial production processes are concerned, the involvement of catalysts is considered to be more than 80%. The processes include pharmaceuticals, energy transition, chemical production and waste disposal.

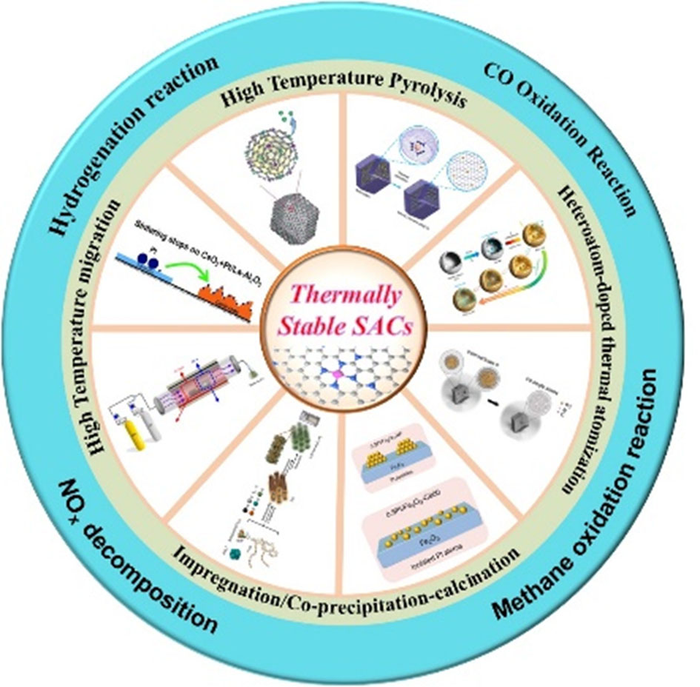

Improving the thermal stability of SACs is the top priority for their promotion to industrial applications. Researchers summarized the basic research on the synthesis methods of thermally stable SACs in recent years, and analyzed the unique mechanism of thermally stable SACs in thermocatalytic applications. Furthermore, they tried to provide theoretical guidance for the determination of the true active centers in the catalytic process and the synthesis of high-activity thermally stable SACs. Image Credit: Chinese Journal of Catalysis.

Improving the thermal stability of SACs is the top priority for their promotion to industrial applications. Researchers summarized the basic research on the synthesis methods of thermally stable SACs in recent years, and analyzed the unique mechanism of thermally stable SACs in thermocatalytic applications. Furthermore, they tried to provide theoretical guidance for the determination of the true active centers in the catalytic process and the synthesis of high-activity thermally stable SACs. Image Credit: Chinese Journal of Catalysis.

To cater to the growing production demands and utmost economic benefits, the development of high-efficiency, steady and affordable novel catalysts has turned out to be a top priority. Being a new field in catalysis, single-atom catalysts (SACs) offer the highest metal atom utilization and smallest active site, which can bring greater economic profits.

At the same time, the atom-support microstructure could be altered rationally. This enables researchers to regulate the electronic structure and geometric structure of the active sites, thereby controlling the catalytic activity and selectivity. But, SACs frequently suffer from sintering in the real thermal catalytic application process. Thus, it is specifically crucial to design SACs rationally from the atomic structure to achieve thermally stable SACs.

A research group headed by Professor Yuen Wu from the University of Science and Technology of China examined the rational construction and practical application of thermally stable SACs.

For the fabrication of thermally stable SACs in a rational manner, it is essential to comprehend the interaction taking place between single-metal atoms and supports in-depth. This is considered to be the foundation for gaining better insight into the SAC’s thermal stability.

The weak physical interaction (van der Waals forces or electrostatic interactions) usually fails to restrain migration and aggregation of metal atoms under the interference of external conditions (high temperature, reducing atmosphere…). In comparison, constructing chemical interaction between metal atoms and supports surface by strong coordination interactions or surface lattice reconstruction is more likely to access thermally stable SACs.

Thus, it is theoretically feasible to achieve thermally stable SACs by building powerful chemical interaction between metal atoms and supports. Keeping this in mind, this review integrated the research outcomes in the past few years and outlined a range of synthetic techniques for thermally stable SACs, like high-temperature migration, high-temperature pyrolysis, heteroatom-doped thermal atomization, etc.

Regarding practical applications, this review put together novel characterization methods and calculation techniques to analyze the catalytic mechanism of thermally stable SACs during the thermocatalytic process. Thermally stable SACs were studied thoroughly in reactions like CH4 oxidation, CO oxidation, selective hydrogenation reaction and so on.

At present, the two major difficulties that exist for the demand of fundamental research and industrial applications of thermocatalysis are improving the active site density of SACs and achieving the large-scale and facile preparation of thermally stable SACs.

From this point of view, rational design of the coordination structure of metal atoms is essential since it contributes a lot to the enhancement and optimization of the catalytic properties of thermally stable SACs.

With novel in situ characterization technologies, scientists could note the dynamic variations during the process of synthesis and catalytic reactions more evidently and thus produce improved catalysts as a result. To understand the commercialization of thermally stable SACs, the large-scale and facile production of thermally stable SACs is another research direction.

If these difficulties are overwhelmed, it can be anticipated that the development of single-atom catalysis will open a new page.

Journal Reference:

Lv, H., et al. (2021) Rational construction of thermally stable single atom catalysts: From atomic structure to practical applications. Chinese Journal of Catalysis. doi.org/10.1016/S1872-2067(21)63888-3.