In recent years, bioprinting has gained popularity as a research technique in various fields. To investigate the use of fuzzy systems as soft computing methods for achieving high precision bioprinting, a team has presented research in Bioprinting.

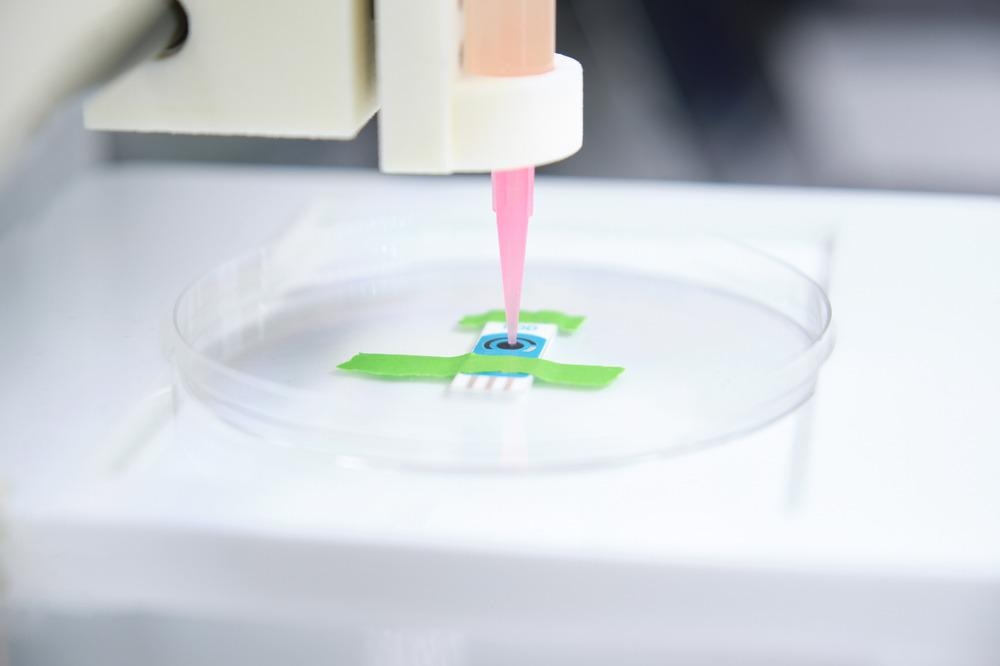

Study: Enhancing precision in bioprinting utilizing fuzzy systems. Image Credit: Ladanifer/Shutterstock.com

Extrusion-based Bioprinting: Fabricating Complex 3D Biological Architectures

Fabricating complex three-dimensional biological structures for use in tissue engineering and drug delivery is a cornerstone of current medical research. To achieve this, bioprinting has been explored extensively in recent studies, with extrusion-based methods emerging as a dominant technology. This is due to the high availability of suitable bioinks that can be used individually or in combination with each other for ease of use and affordability.

Extrusion-based bioprinting methods deposit bioinks layer-by-layer to produce the complex 3D architectures that are necessary for applications such as tissue transplant and implantation, producing in-vivo and in-vitro models for drug discovery, and in-vitro cell-cell interaction visualization for cancer treatments in a biomimetic microenvironment. Computer-aided design (CAD) methods are used to generate these bioprinted constructs and they can be quickly reproduced from an ever-expanding library of available bioinks.

Parameters for extrusion-based bioprinting that affect the final product include nozzle gauge, printing speed, pressure in the syringe, the temperature of the material, and crosslinking status. These parameters must be optimized to generate a construct with the appropriate material properties and desired architecture and dimensions.

However, due to the variability of customized bioinks, determining printability with universal parameters is difficult. Design of experiment (DOE) modeling is not appropriate, and whilst machine learning can help accurately identify and predict relationships in single and multi-component inks, the appropriate machine learning methodology must be selected.

The Advantage of Fuzzy Logic Methods

Generally speaking, the limitation of standard mathematical modeling is a lack of generalization once a specific number of inputs is surpassed. Furthermore, linearization leads to inaccuracy and imprecision in output approximation for bioink formulations, making them unsuitable for accurately modeling these materials and the resulting printed structures.

In standard logic, values can only be completely true or completely false. Fuzzy logic is an extension of this logic, where values have a degree of truth, with the value expressed between 0 and 1. Fuzzy logic allows the elucidation of continuous values rather than discrete ones.

Further Reading: 3D Printing with Photocurable Resin

Fuzzy computing systems may be superior methods due to their robustness in parameter modeling and the control of noise in the data, especially for unseen data points. Implementing a fuzzy logic system can optimize parameters, leading to high precision in bioink formulation.

Facilitating High Precision in Bioink Formulation with Fuzzy Logic Systems

Due to the advantages of fuzzy logic for elucidating continuous values in mathematical modeling, the team behind the study in Bioprinting has developed a system based on this system. Collagen and Pluronic F-127 bioinks were used in the study. These bioinks were both diluted or undiluted in αMEM culture media.

The inputs in the system chosen by the authors were printing speed, nozzle pressure, and the percentage dilution of the bioinks. A single output of line width was selected. By optimizing the parameters such as extrusion pressure, dilution percentage, and printing speed, line width can be accurately approximated. Other parameters that maximize precision in printing can also be determined using a fuzzy logic system.

Results of the study indicated that the approach could optimize printing parameters and improve reproducibility across a diverse range of bioinks. Moreover, the authors have stated that a fuzzy logic approach can provide an objective characterization of the precision of bioprinting using newly formulated bioinks.

The authors also defined the Bioink Precision Index in the study, which can be easily used to compare how printing can be reproduced over a variety of single components and composite bioinks that are currently commercially available. This will aid the future development of bioinks for use in fields such as tissue engineering, drug discovery, and drug delivery.

What This Means for Printing Viable Biological Structures

This research has demonstrated that modeling based on fuzzy logic systems is advantageous for optimizing the parameters of extrusion-printed architectures and bioink selection. Being able to create reproducible biological structures with high precision is vital for the mass production of bioprinted products for the biomedical field, both for research and practical purposes.

The study published in Bioprinting has provided a significant knowledge database for future studies using fuzzy logic systems to produce viable 3D printed biological architectures that will aid research and development in the biomedical industry. The authors have stated that an extended approach may be needed for future research that considers parameters such as biocompatibility and cell viability, which affect bioprinting and its experimental outcomes.

Further Reading

Sedigh, A et al. (2022) Enhancing precision in bioprinting utilizing fuzzy systems [online] Bioprinting | sciencedirect.com. Available at: https://www.sciencedirect.com/science/article/pii/S2405886621000634

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.