The urgent issue of plastic waste has facilitated research into valorization strategies to turn it into useable products which meet the aims of the circular economy concept. One strategy is to convert oil from plastic waste into fuel to help the transportation industry meet its net zero carbon targets and enhance compression injection engine performance.

Study: Exhaust Gas Recirculation on a Nano-Coated Combustion Chamber of a Diesel Engine Fueled with Waste Plastic Oil. Image Credit: NadyGinzburg/Shutterstock.com

A study published online in Sustainability has explored this research area, presenting an engine concept that utilizes fuel from plastic waste and recirculated exhaust gases.

Ending the Dominance of Oil

Whilst the world is rapidly decarbonizing, the demand for oil is still high. A recent report by BP has stated that the majority of the world’s primary energy production needs are met by oil at 31.2%, followed by coal and natural gas. As a fuel, oil has both its advantages and drawbacks. It is a reliable energy source and can easily provide energy security. However, like all fossil fuels, use comes with a massive, well-documented environmental cost.

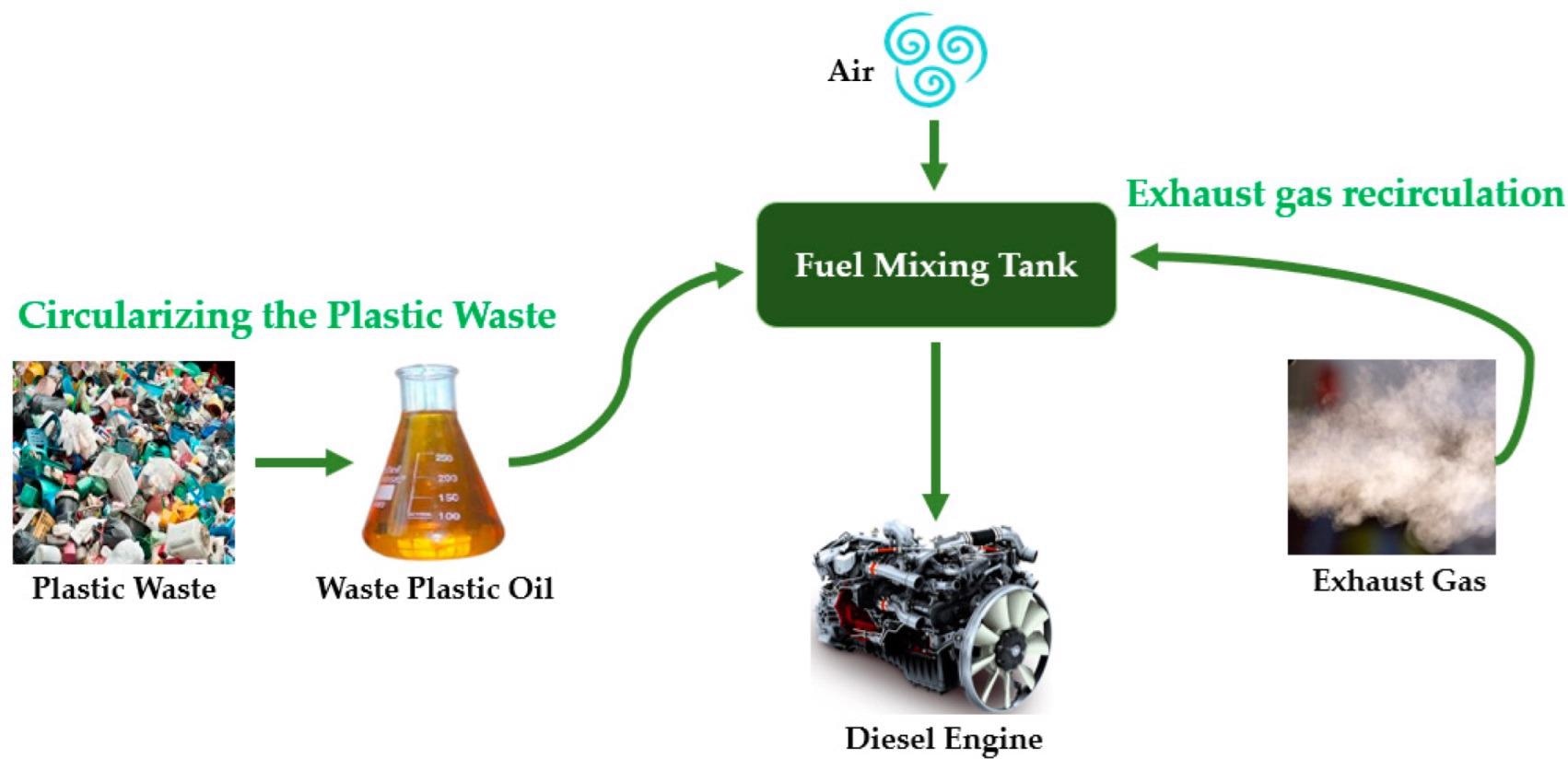

Use of waste plastic oil and exhaust gas recirculation in line with the circular economy. Image Credit: Saravanan, P et al., Sustainability

The environmental cost of oil comes in the form of greenhouse gas emissions which are driving global climate change and on a global level, emissions are increasing. Data gathered by the Global Carbon Project has shown that emissions caused by oil consumption have increased from 9.35 million tons in 1750 to 13.98 billion tons in 2020. This figure represents a relative change of +149,369%.

Recognizing the scale of the problem, world governments have agreed to reduce their emissions to net-zero by 2050. To meet these targets, many technological solutions have been presented, notably renewable energy generation. However, renewable energy, whilst improving in capabilities, does suffer from some drawbacks in terms of meeting rising global energy demands. Challenges include a non-existent systems approach, lack of social innovation and acceptability, and key technological issues.

Whilst there has been a significant push to revolutionize the transport industry and introduce low-emission vehicles, the demand for liquid fuels still exists and could do so past 2040. Exploring alternative liquid fuels such as biofuels and waste-derived fuels and alternative design paradigms could meet the demands of both engine performance and reducing environmental harm.

Converting Waste Plastic into Fuel

Alongside greenhouse gas emissions, a critical environmental issue is the growing amount of plastic waste. Valorization of plastic waste by converting it into sustainable fuel could provide significant advantages for the vehicle industry as well as for pollution clean-up efforts. Plastic waste can be converted into liquid fuel similar to diesel by the process of electrical pyrolysis and any impurities are removed using fabric and micron filters.

Studies have recently explored using alternative fuels and exhaust gas recirculation (EGR) in compression injection engines. Oil produced from waste plastic has been proposed for this purpose, due to the balance needed between resource circularity and consumer needs. Additionally, the possibility of developing multi-commodity production systems has arisen in current research, which uses a low-value commodity for CI engines and a high-value commodity for carbon capture.

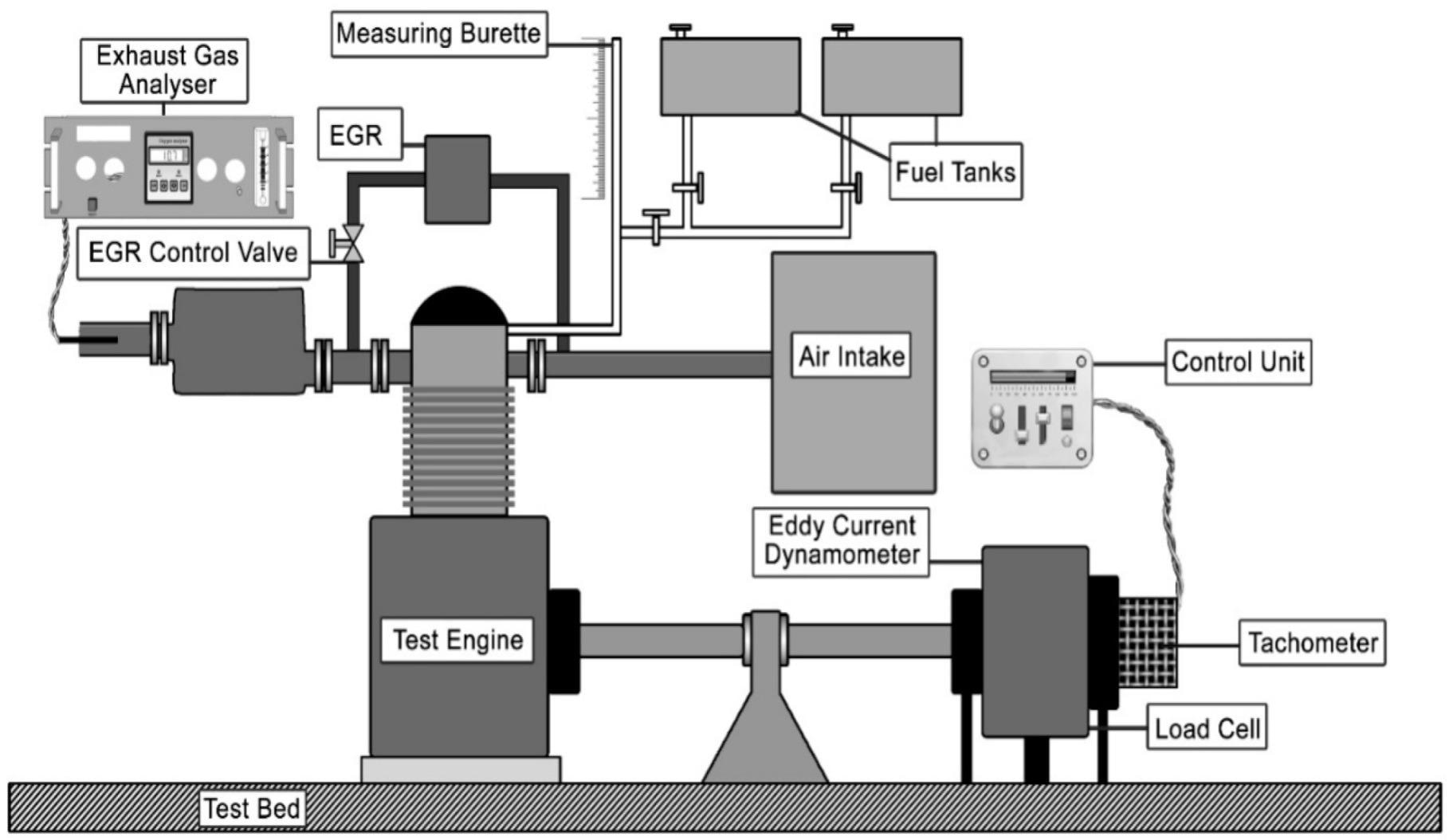

Schematic representation of test engine setup used for the experiment. Image Credit: Saravanan, P et al., Sustainability

However, few studies have concentrated on using system design aspects and thermal barrier coating methods to enhance the performance of compression injection engines. Amongst thermal barrier coating materials, nano-coating materials have recently emerged as intriguing candidates.

Alternative fuels have been widely explored for their emissions reductions, but thermal efficiency limitations have been identified. For this reason, it has been proposed that a combination of alternative fuels and EGR could enhance thermal efficiency. There is a growing body of literature in this research area.

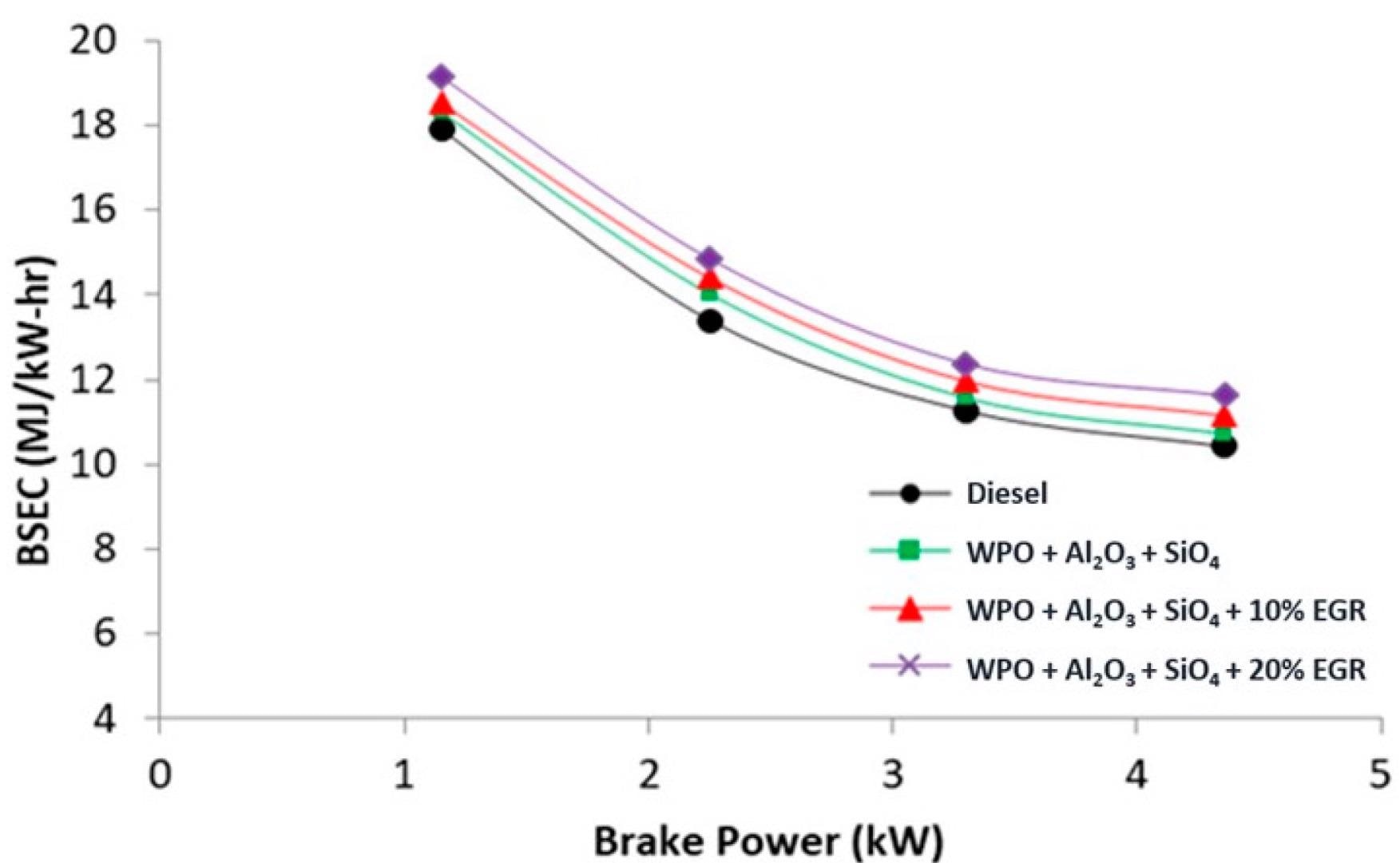

Variations of brake-specific energy consumption with brake power. Image Credit: Saravanan, P et al., Sustainability

The Study

The study in Sustainability has explored using fuel from plastic waste and EGR technologies with thermal barrier coatings on compression injection engine components to enhance engine performance, to develop an engine concept that will meet both consumer requirements and the need to reduce the environmental impact of the transport industry whilst exploring a more circular manner of fuel production.

In the engine design presented by the authors, the pistons, cylinder heads, and valves were coated with Al2O3-SiO4. Scenarios were tested with different EGR percentages. Additionally, the system was compared with conventional diesel fuel.

Results of the experiments demonstrated that the thermal coating on the piston crowns increased the engine’s combustion performance. Moreover, nitric oxide, hydrocarbons, and carbon monoxide emissions were reduced. The authors have stated that, overall, WPO with EGR could be advantageous as an alternative fuel to diesel for future compression injection engines, meeting the power and environmental demands of the vehicle industry.

Further Reading

Saravanan, P et al. (2022) Exhaust Gas Recirculation on a Nano-Coated Combustion Chamber of a Diesel Engine Fueled with Waste Plastic Oil [online] Sustainability 14(3) 1148 | mdpi.com. Available at: https://www.mdpi.com/2071-1050/14/3/1148

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.