Recently published papers1,2 highlight the potential to use multiple properties measurable with the FT4 Powder Rheometer® from Freeman Technology, a Micromeritics company, to quantify an Additive Manufacturing Suitability (AMS) factor capable of ranking the printability of metal powders in laser powder bed fusion (LPBF) processes.

Answering the question ‘Can I print with this?’ is vital for those working with popular AM processes such as LPBF but can be surprisingly difficult. The AMS factor approach is simple, effective, and efficient. It combines dynamic, shear and bulk powder properties measured with the FT4 into a single metric to sensitively differentiate printability in a way that conventional powder testers cannot. This valuable approach is summarised in a new application note which is freely available for download.

Image Credit: Freeman Technology

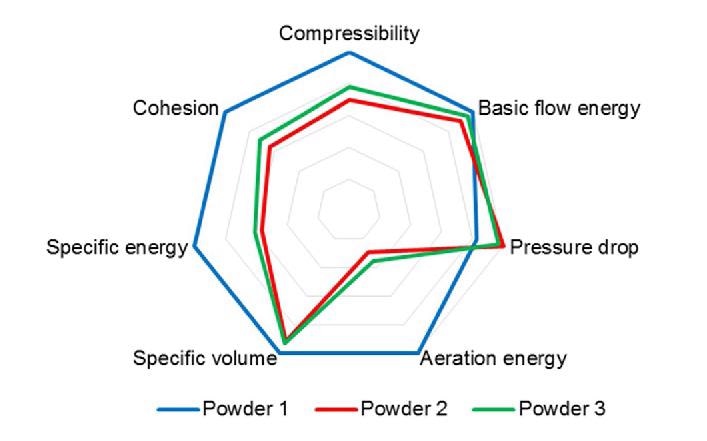

AM powders, in development or alternative commercial supplies, are often assessed via print trials because of the difficulty of establishing a relevant specification. This is time-consuming, inefficient, and potentially costly. Researchers at the Ecole de Technologie Superieure (Montreal, Canada)1 noted the relevance of multiple FT4 properties and combined them into a single metric, the AMS, to rank the processability of Ti-6Al-4V powders. The resulting AMS values were then successfully correlated with print performance. In contrast, traditional powder testing techniques, such as flow through an orifice and tapped density methods, proved unable to provide sensitive and relevant differentiation. Building on this concept, a second group, an industrial collaboration, used a modified AMS factor to successfully assess the processability of powders for in situ alloying in a LPBF process2.

“Many in the AM community, from powder and machine suppliers to end-users, would like to be able to reliably test a powder for printability,” said Mr Jamie Clayton, Operations Director, Freeman Technology.

“Work such as this demonstrates progress towards this goal, emerging consensus with respect to the need to measure multiple parameters, and the value of dynamic flow properties. We’re delighted that the FT4 can successfully rank print performance. For us powder testing is all about improving process efficiency and product performance and this is a great example of it doing just that.”

To find out more about the AMS factor and how it can help with the selection of metal powders go to: www.freemantech.co.uk/news/the-concept-of-an-am-suitability-factor-for-metal-powder-selection

References

1 S.E. Brika et al ‘Influence of particle morphology and size distribution on the powder flowability and laser powder bed fusion manufacturability of Ti-6Al-4V alloy. Additive Manufacturing 31 (2020) 100929

2 M.S. Knieps et al ‘In situ alloying in powder bed fusion: The role of powder morphology’ Mat Sci and Eng A, 807 (2021) 140849

Freeman Technology and Powder Rheometer are registered trademarks of Freeman Technology Ltd.