.jpg) By Susha Cheriyedath, M.Sc.Reviewed by Skyla BailyJan 26 2022

By Susha Cheriyedath, M.Sc.Reviewed by Skyla BailyJan 26 2022A group of researchers recently published a paper in the journal Materials that determined the optimum operating conditions in a cement solidification method, to effectively solidify the radioactive lime waste produced by the neutralization of liquid wastes obtained from the ammonium uranyl carbonate (AUC) ((NH4)4UO2(CO3)3) wet process.

Study: Evaluation of Disposal Stability for Cement Solidification of Lime Waste. Image Credit: Kunertus/Shutterstock.com

Background

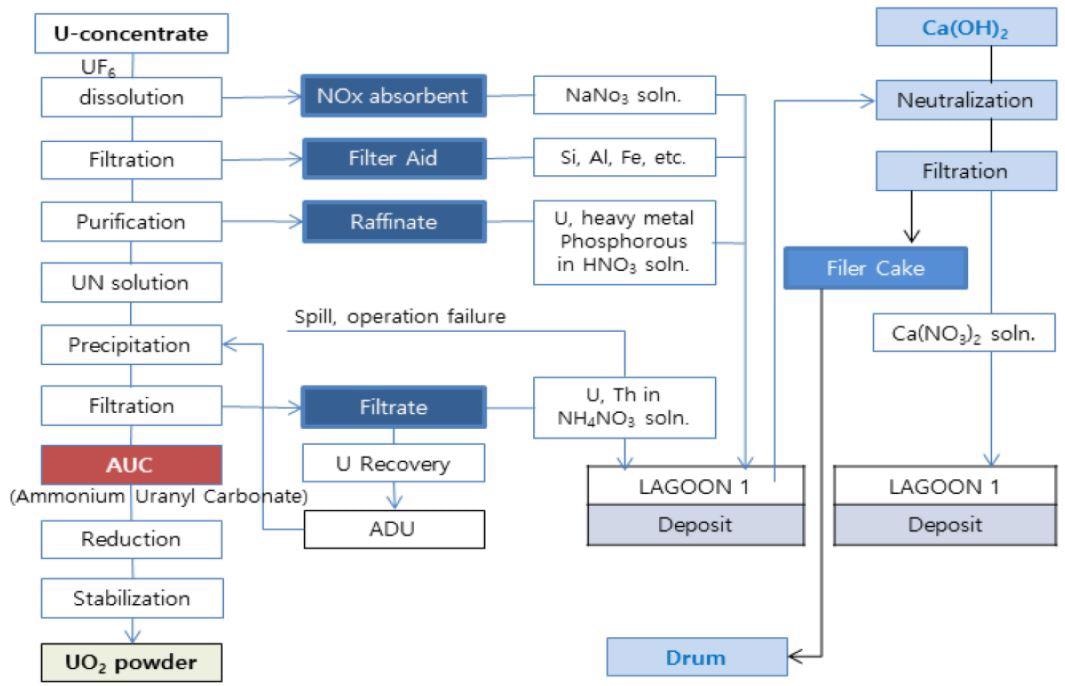

Radioactive waste produced during the decommissioning and operation of nuclear power plants is usually processed by the AUC wet process. This process is primarily a uranium reconversion process involving substantial amounts of nitric acid (HNO3) and AUC. Liquid wastes generated from the AUC wet process are neutralized using the hydrated lime (Ca(OH)2), and the byproduct obtained after neutralization is referred to as radioactive lime waste.

Appropriate procedures should be followed to ensure stable disposal of the lime waste, and the lime waste must undergo cementation to fulfill waste acceptance criteria (WAC). Additionally, the chemical and physical characteristics of the cement waste form produced after the cementation of the lime waste should satisfy the WAC. The cementation of lime waste must be an affordable and simple process. Various cementation processes with multiple solidifying mediums were developed for glass, asphalt, cement, and polymer.

Among these processes, the cement solidification technique is the most efficient process owing to the use of well-known technology and materials, reasonable cost, and extensive applications. In this study, researchers determined the optimum operating conditions for the cementation of the lime waste produced from the AUC wet process and evaluated the leaching stability and structural stability of the cement waste form samples.

Schematic diagram of reconversion process and waste. Image Credit: Shon, J.-S et al., Materials

The Study

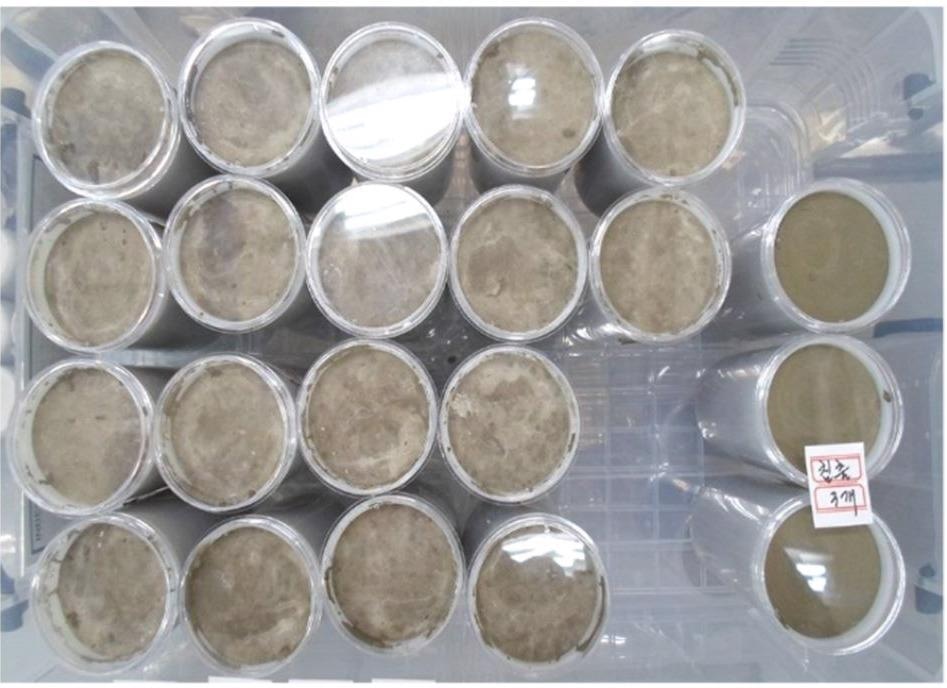

Low-level radioactive lime waste used in the experiment was dried at 105oC for 24 h. A mortar was used to pulverize the dried lime waste to prepare uniform samples of cement waste form. Portland cement (type I) was utilized for the cementation of lime waste. The shape stability of the cement compound and the lime waste was evaluated with different lime waste contents of 80, 75, and 71 wt.% in cement waste form samples.

The weight ratio of the lime waste was kept at 75 wt.%, and different water-to-cement (w/c) ratios of 2.40, 2.20, 2.00, 1.95, 1.85, 1.75, 1.65, and 1.55 were utilized to calculate the optimal mixing ratio. The lime waste and the cement waste form were mixed using a mechanical mixer, and then the mixtures were poured into polyethylene molds at a relative humidity range of 30-60% and 18-25 oC temperature.

The molds were cured for 28 days, and lids were used to cover the molds during that duration in order to prevent the evaporation of moisture. The workability test was performed to determine the range of w/c ratios that allows cement mixtures to possess the flowability required for cementation. WAC was employed as the evaluation criteria and method for testing the leaching stability and the structural stability of the cement waste form samples.

The disposal feasibility of the cement waste form samples cured at a w/c ratio of 2.0 was evaluated by water immersion, irradiation, and thermal recycling tests. The leaching test was conducted as an inactive test and the leachability index (LX) was used to evaluate the leachability of cement waste form samples.

Observations

At a lime waste content of 80 wt.%, the cement mixture samples collapsed upon the removal of polyethylene molds after curing, indicating the need for a lower value of the maximum lime waste content. Thus, the weight ratio of lime waste was fixed at 75 wt.% after considering the shape stability and economic feasibility of cement waste form samples.

Curing of specimen that blocked movement of moisture with lid closed. Image Credit: Shon, J.-S et al., Materials

Observations from the workability of cement-lime mixtures indicated that the mixtures possess good flowability at a w/c of 1.95 or higher and no flowability at a w/c of 1.75, 1.65, and 1.55. The range of w/c ratios with acceptable flowability and mixability for the preparation of cement waste form samples was 1.90-2.30 when the lime waste content was 75 wt.%.

The weight of the cement waste form samples decreased by 7.33%, 15.00%, and 16.25% after the water immersion test, irradiation test, and thermal recycling test, respectively, while the volume changed by 0.3% after every test. Initially, the compressive strength of cement waste form samples after curing was 55.0 kgf/cm2, which increased to 61.0, 76.3, and 61.4 kgf/cm2 after the irradiation test, water immersion test, and thermal recycling test, respectively; this is higher than the acceptance criterion of 35.2 kgf/cm2.

Observations from the leaching test of the cement waste form samples indicated that the LXs of cobalt (Co), strontium (Sr), and cesium (Cs) nuclides were 10.89, 8.02, and 7.63, respectively, which was higher than the acceptance criterion of 6.

To summarize, the proposed cement solidification method for disposing of radioactive lime waste can be an effective approach to the cementation of lime waste powder produced during the neutralization of liquid wastes in the AUC wet process.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Shon, J.-S., Lee, H.-K., Kim, G.-Y. et al. Evaluation of Disposal Stability for Cement Solidification of Lime Waste. Materials 2022, 15, 872. https://www.mdpi.com/1996-1944/15/3/872