A pre-print study posted to the server Research Square, in submission to the journal Cellulose, has investigated the development of a single-step deposited flame-retardant coating for paper products.

Study: Polymeric Coacervate Coating for Flame Retardant Paper. Image Credit: ex_artist/Shutterstock.com

Cellulosic paper products are widely used for packaging, cardboard, printing, and construction, but a major issue with them is their flammability. Whilst there has been significant research into coating individual wood fibers with flame-proof materials, few studies have been performed regarding fire-retardant coatings for already-cast paper.

Flame-Proofing Paper: Current Perspectives

Contractor’s paper is made from wood pulp which, despite its utility for multiple applications, low cost, recyclability, and biodegradability, is flammable. This has led to the loss of historic documents in several fires, as well as increasing the risk of house fires when used in home improvement projects and as roofing materials. Cotton, another commonly used material in various industries, exhibits similar flammability which has led to several researchers applying strategies for fireproofing cotton to better protect the cellulosic paper.

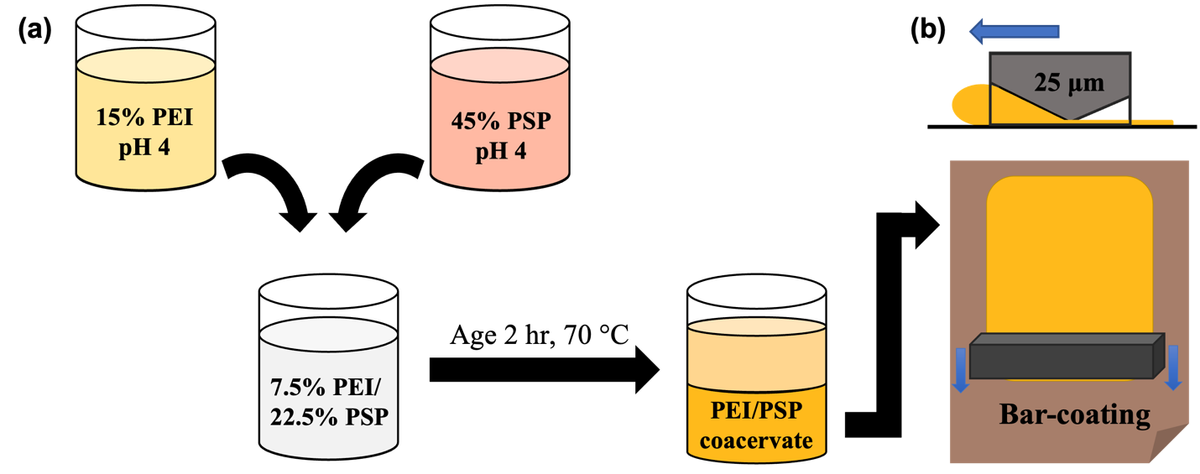

Preparation (a) and application (b) of the PEI/PSP coacervate. Image Credit: Palen, B et al., Cellulose

Previous research into fireproofing cellulosic paper has concentrated on depositing flame-retardant materials onto individual cellulosic fibers and introducing them into paper during the production process. Several deposition methods have been explored, including layer-by-layer assembly. In this method, nanoparticles and/or anionic and cationic polyelectrolytes are alternately deposited into a substrate material and held together by electrostatic interactions.

Layer-by-layer deposition imparts paper products with a superior gas barrier, heat shielding, and flame-retardancy properties. Additionally, this deposition layer also works for substrates including cotton and other cellulosic materials. However, despite these superior flame-proofing properties, it is a time-consuming and costly process due to multi-step processing.

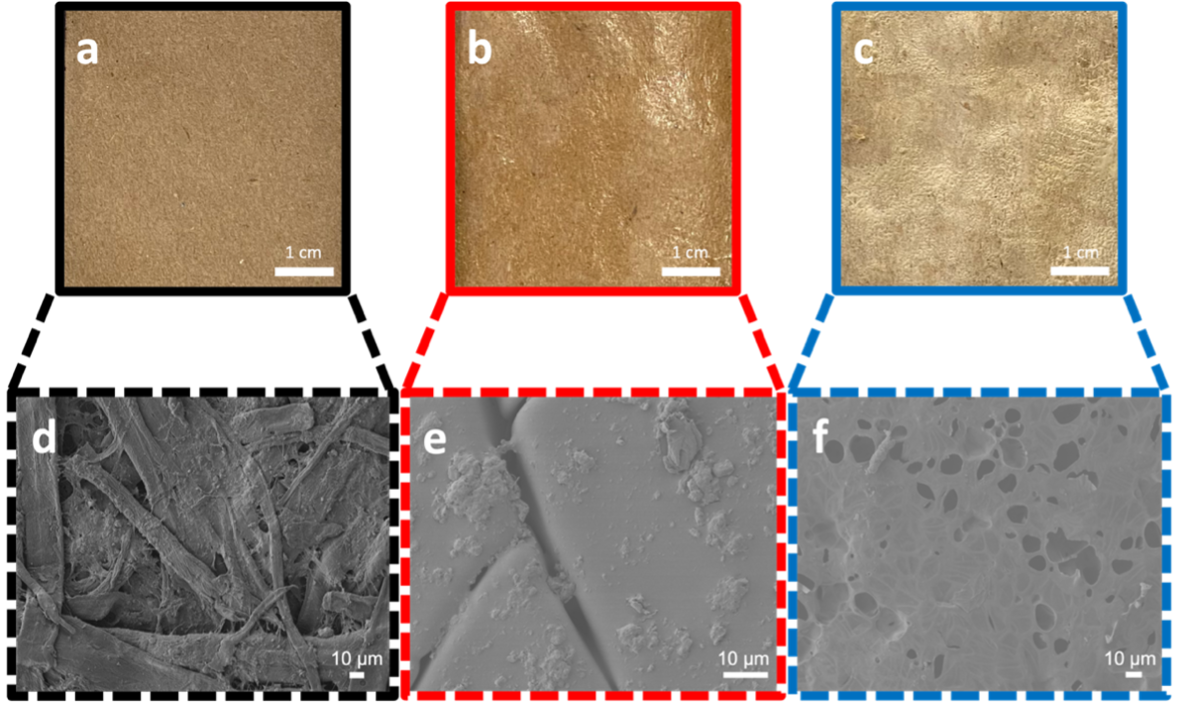

Photographs (top) and SEM images (bottom) of uncoated (a,d), coated (b,e), and crosslinked (c,f) paper, respectively. Image Credit: Palen, B et al., Cellulose

Polyelectrolyte Complexes

An alternative to layer-by-layer deposition, polyelectrolyte complexes have been explored in recent years for imparting flame-proofing properties into substrate materials. In this process, oppositely charged polyelectrolytes are simultaneously deposited in a single step. Mixing cationic and anionic polymers together in the process either creates a soluble, insoluble, or coacervate (elastic) liquid solution.

An entropically driven complexation is governed by intrinsic and extrinsic interactions which can be manipulated by adjusting the salt concentration and pH. Two distinct phases emerge when the electrostatic interactions in the solution are limited by counter ions: a polymer-dense coacervate phase and a polymer-poor solution phase. The coacervate phase is viscous and thus suitable for coating substrate materials.

Coacervate phases have proven fire retardancy and gas barrier properties, but a drawback is their tendency to absorb moisture. To overcome this issue, they can be mediated via the incorporation of clay nanoplatelets or a crosslinking agent.

The Study

In the present study, the authors have developed a single-step process for the purpose of introducing flame-resistant properties into contractor’s paper. The coating consists of a coacervate of poly(sodium) phosphate and polyethyleneimine crosslinked with glutaraldehyde to reduce sensitivity to moisture.

The crosslinking was confirmed using Fourier-transform infrared spectroscopy. This was caused by the glutaraldehyde crosslinking the film’s amine groups (which was sourced from polyethyleneimine) by forming a Schiff base. The disappearance of the primary amine peak when the material was analyzed provided evidence of this. Additionally, hydroxyl peaks, indicative of significant water uptake, present in non-crosslinked polymer films were not detected in the glutaraldehyde-crosslinked film.

Additionally, a color change in the paper following exposure to glutaraldehyde indicates the presence of crosslinking. Whilst the original brown color of the paper is retained after crosslinking, the coating changes from colorless to opaque, indicating a chemical change. Morphological changes in the paper when coated with the cross-linked coacervate solution were observed. The porous structure of the uncoated paper was filled by the coating, yielding a smooth, conformal surface.

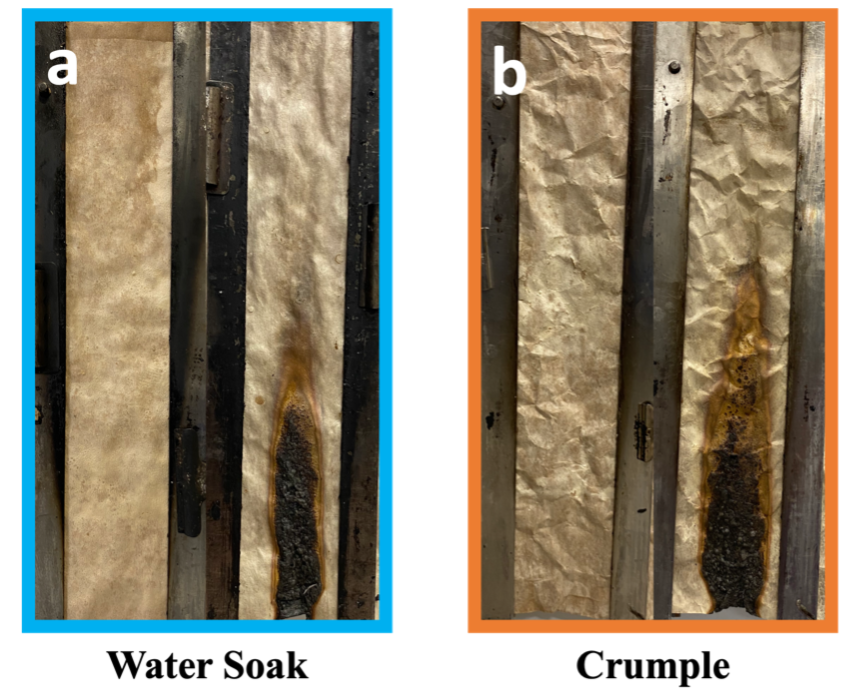

Pre- (left) and post-burn (right) images for PEI/PSP crosslinked coating on paper after water soak (a) and crumpling (b). Image Credit: Palen, B et al., Cellulose

Due to the smooth surface of the coated paper, it was hypothesized by the authors that the coating would possess superior gas barrier properties. A 90% reduction in the oxygen transfer rate was observed in the non-crosslinked coating, which was reduced to 35% after crosslinking. The authors concluded that this could be due to a combination of weight gain and surface morphology. SEM revealed that microscopic craters were present, which functioned as weak points for oxygen transfer.

Vertical flame testing was conducted on uncoated, coated, and crosslinked paper to evaluate flame retardant behavior. The crosslinked coating gave the paper self-extinguishing behavior, whilst the non-crosslinked and uncoated paper displayed significant charring. Furthermore, the crosslinked coacervate film resisted conditioning tests manual crumpling and water soaking and retained the ability to self-extinguish despite small cracking after conditioning.

Based on the results of experiments in the study, the authors have stated that the novel crosslinked coacervate coating can be used for flame retardancy purposes. Being a single-step process, there are significant time and cost advantages over conventional deposition techniques such as layer-by-layer deposition.

Finally, the authors have identified that the gas barrier of the coating could be improved, whilst retaining its flame-proofing properties, by modifying the chemistry and/or concentration of the crosslinking agent.

Further Reading

Palen, B et al. (2022) Polymeric Coacervate Coating for Flame Retardant Paper [online] Cellulose [pre-print] researchsquare.com. Available at: https://www.researchsquare.com/article/rs-1290021/v1

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.