In a recent study published in the journal Materials, researchers from Poland analyzed casein as a potential coating material to prevent corrosion of magnesium (Mg)-based alloys when used in orthopedic implants. Mg is a biocompatible material that self-decays inside the human body.

Study: The Influence of Casein Coatings on the Corrosion Behavior of Mg-Based Alloys. Image Credit: nadisja/Shutterstock.com

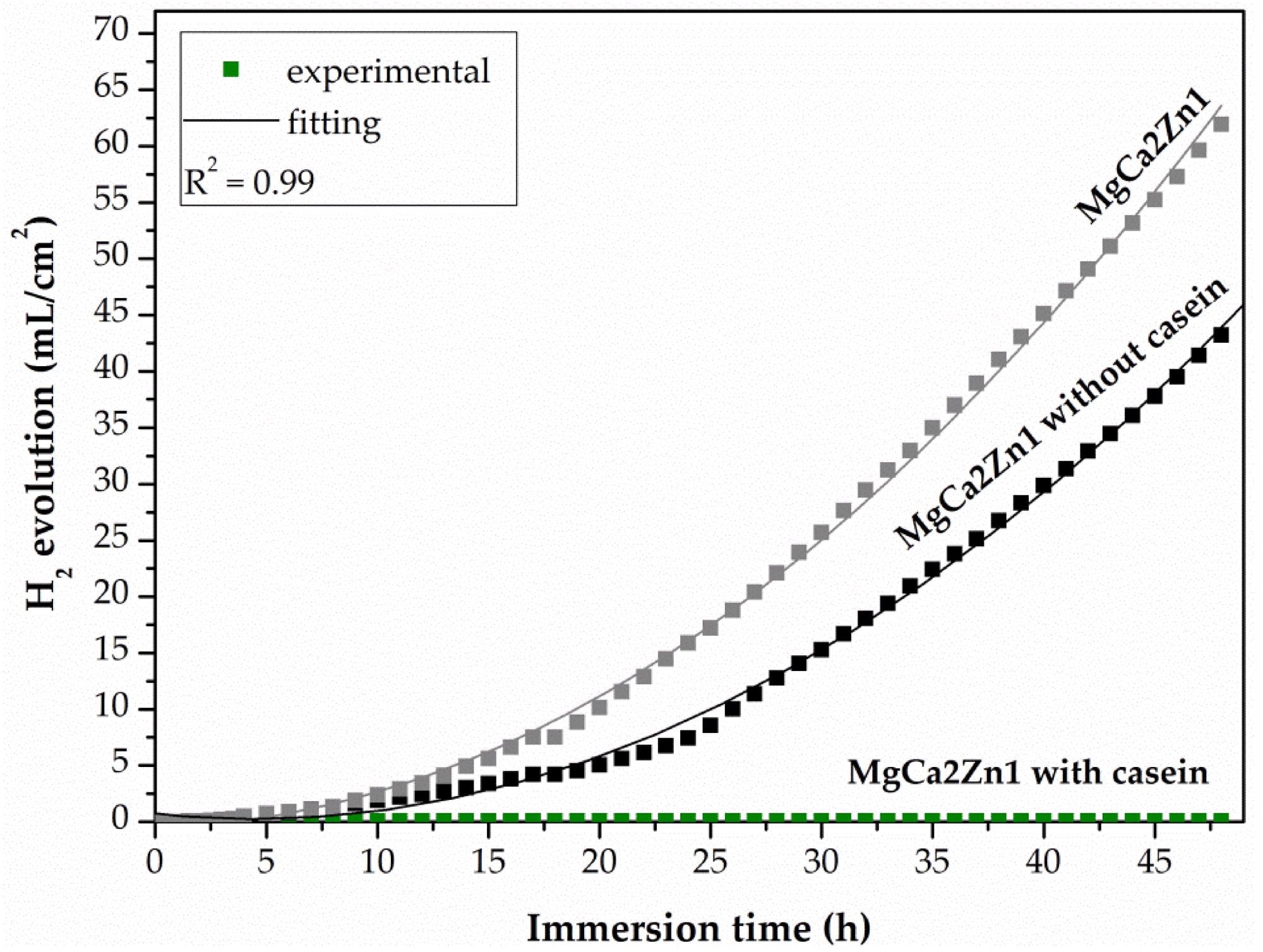

The casein coating effectively reduced the degradation of two Mg-based alloys, namely MgCa2Zn and MgCa2Zn1Gd3. This was evident from the high corrosion potential, high polarization resistance, and low hydrogen release when immersed in Ringer solution.

Casein-coated MgCa2Zn1 and MgCa2Zn1Gd3 alloys released 19.25 and 12.42 mL/cm2 of hydrogen, respectively, when immersed for 216 hours. Moreover, gadolinium (Gd)-doped Mg-alloy, MgCa2Zn1Gd3, exhibited the lowest corrosion rate.

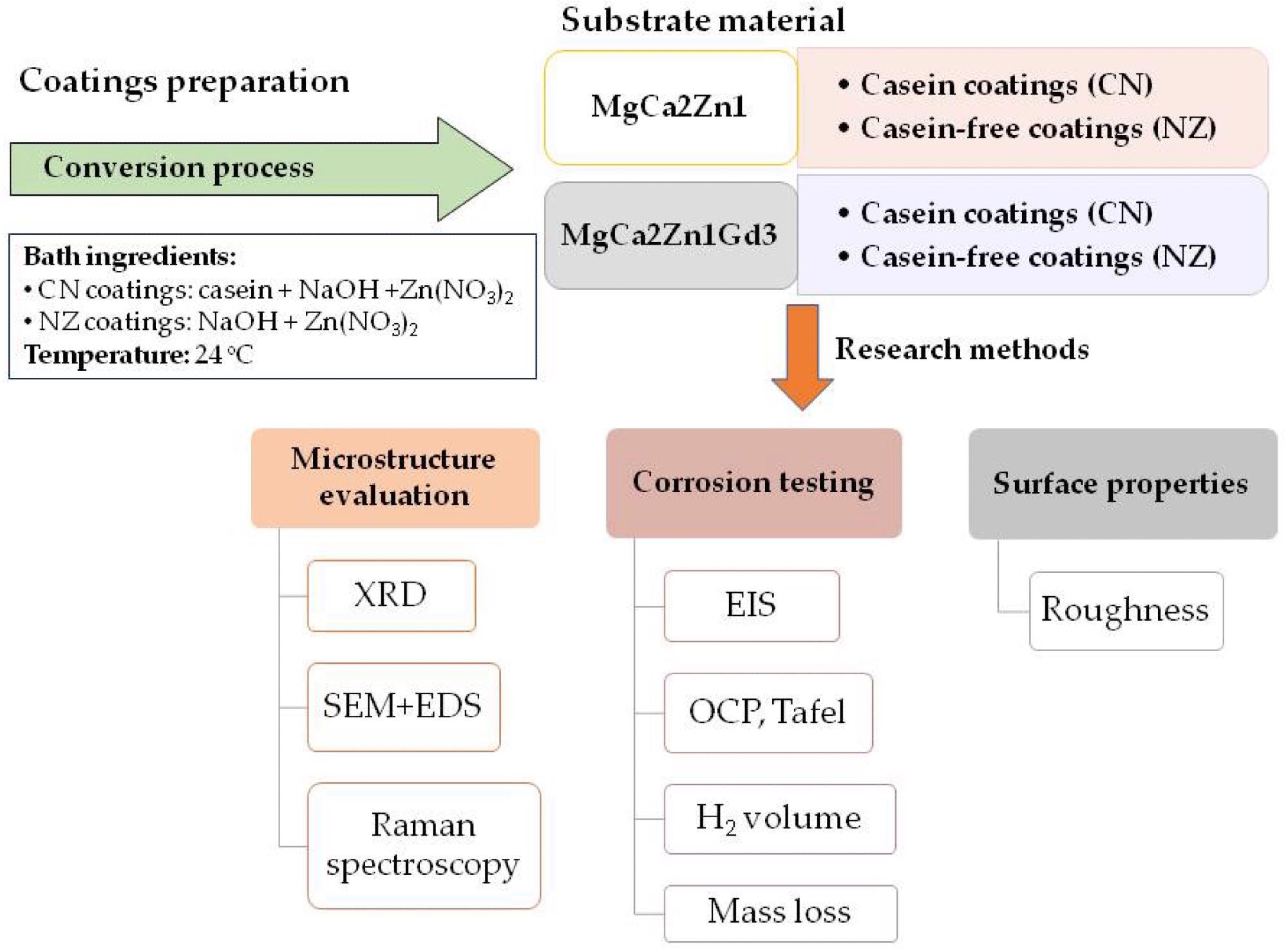

Diagram of research performed in the work. Image Credit: Kania, A et al., Materials

Increasing Lifespan of Mg Alloy-based Implants

Mg-based alloys are extensively used for orthopedic implants owing to their biocompatibility, similar density and yield strength to that of human bone, and most importantly their biodegradability. The recuperative type implants need to be removed from the body after the damaged bone or tissues recover unless they are biodegradable. Thus, Mg alloy-based implants are a comfortable, cost-effective, and eco-friendly solution.

Controlling the lifespan and dimensionality of Mg alloys in a body fluid environment to match with the recuperation pace of bones and tissues without causing discomfort is an ongoing field of research. The degradation/corrosion rate of Mg alloys is often expressed by the rate at which hydrogen (H2) gas is released.

There are many approaches to increase the corrosion resistance of Mg alloys. The first approach is to control the microstructure, i.e., promoting fine grain size, reducing precipitation of secondary alloy phases, and eliminating impurities in grain boundaries. Moreover, many alloying elements such as Gd improves the resistance to oxidation at high temperature. It is ferromagnetic below its Curie temperature of 20℃. Many previous studies also have shown that Gd decreases the degradation rate of Mg alloys. The addition of Gd increases the Mg(OH)2 content on the alloy surface that slows down the dissolution of corrosion products.

Calcium and phosphorus-rich casein are found in milk, which helps in bone growth. Previously, casein and chitosan-coated Co-Cr-Mo alloy demonstrated zero cytotoxicity. Hence, casein can be a potential coating material that can slow down Mg degradation in the body fluid environment.

About the Study

In this study, researchers fabricated casein-coated two Mg alloys viz. MgCa2Zn1 and MgCa2Zn1Gd3. Both alloys prepared by induction melting at 750 ℃ had a cylindrical shape with 13 mm diameter and 6 mm height. The surfaces of samples were polished with SiC paper and diamond suspension, followed by cleansing in acetone and distilled water. All samples were conversion/dip-coated in two types of baths, one consisted of casein and another one did not.

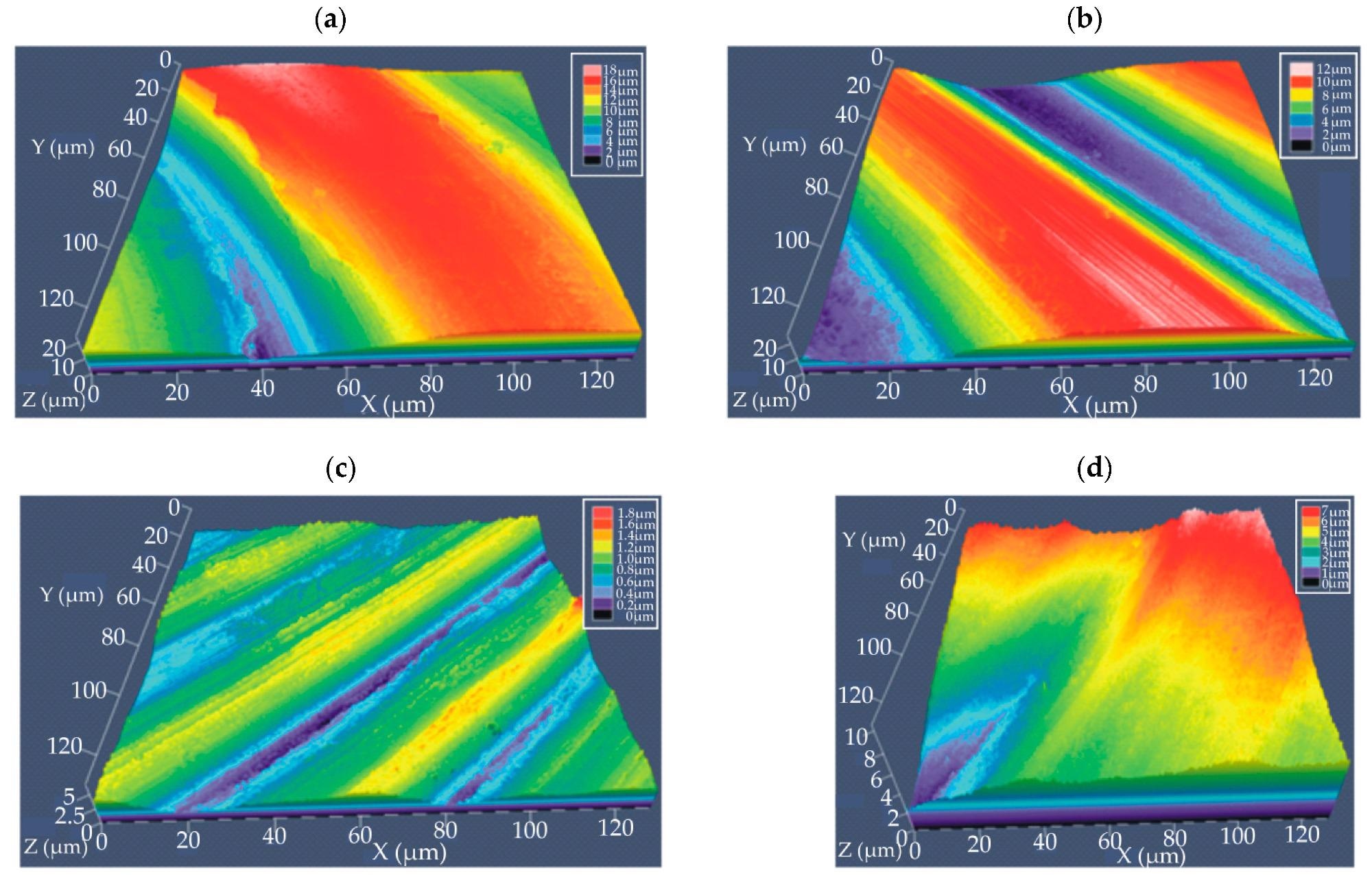

Confocal images of conversion coatings surface topography deposited on MgCa2Zn1 alloy: (a) casein coating (CN); (b) casein-free coating (NZ), and MgCa2Zn1Gd3 alloy: (c) casein coating (CN); (d) casein-free coating (NZ). Image Credit: Kania, A et al., Materials

The casein (CN) bath was comprised of casein, NaOH, and Zn(NO3)2, whereas the casein-free (NC) bath consisted of only NaOH and Zn(NO3)2. Samples were immersed in chlorine (Cl)-rich Ringer solution at 37 ℃ for 48 hours and the volume of released H2 was measured.

Observations

Scanning electron microscopy (SEM) images showed that the casein and casein-free coatings had an average thickness of 20 and 22 µm, respectively. The casein coatings were more porous and compact than casein-free coatings. Moreover, the roughness value of casein-coated MgCa2Zn1Gd3 alloy was lower than that of MgCa2Zn1 owing to the presence of Gd content, which reduced the microporosity by preventing the shrinkage of the alloy during casting.

Polarization curves of casein coated, casein-free coated, and uncoated MgCa2Zn1 alloys were in the current range of 10-2–10-3 A.cm-2, which was higher than that for MgCa2Zn1Gd3 alloys (i.e., 10-3–10-4 A.cm-2). That indicated Gd containing Mg alloy had higher corrosion resistance. Meanwhile, all types of coated alloys exhibited higher corrosion resistance than uncoated alloys. Similarly, coated samples demonstrated higher corrosion potentials, higher polarization potentials, and lower corrosion current densities.

The Bode representation of phase angle vs. frequency showed that the casein-doped coating exhibited a larger phase angle and impedance modulus over a wide range of frequencies than the casein-free specimen. Furthermore, the casein-coated MgCa2Zn1 and MgCa2Zn1Gd3 alloys released 19.25 and 12.42 mL/cm2 of H2, respectively, when immersed in Ringer solution for 216 hours. The lower the volume of H2 released, the higher the corrosion resistance.

Volume of hydrogen evolution as a function of immersion time in Ringer solution at 37 °C for 48 h for the coatings applied to the MgCa2Zn1 alloy and uncoated alloy. Image Credit: Kania, A et al., Materials

Conclusions

To conclude, the researchers of this study fabricated casein-coated, casein-free-coated, and uncoated Mg alloys viz. MgCa2Zn1 and MgCa2Zn1Gd3 . The coated samples of both alloys exhibited higher corrosion potential, high polarization potential, and lower volume of H2 release than the corresponding uncoated alloy. This shows that the coated samples effectively reduced the degradation of Mg alloys in Ringer solution. Based on the same parameters, it is evident that the casein-coated Gd-doped Mg alloy exhibited better corrosion resistance than standard Mg-Ca-Zn alloy.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Kania, A., Cesarz-Andraczke, K., Brytan, Z., Reimann, Ł., Smolarczyk, P., The Influence of Casein Coatings on the Corrosion Behavior of Mg-Based Alloys. Materials 2022, 15, 1399, https://www.mdpi.com/1996-1944/15/4/1399