Manufacturing biopolymers from agricultural and industrial wastes is a growing area of research in materials sciences. Exploring the potential for producing commercially viable biopolymers from plantain agro-industrial waste, a team of researchers has published a new paper in Polymers.

Study: Development and Characterization of Plantain (Musa paradisiaca) Flour-Based Biopolymer Films Reinforced with Plantain Fibers. Image Credit: Jacobo Castro Cristo/Shutterstock.com

Producing Sustainable Biopolymers and Biocomposites

Plastic is one of the most revolutionary materials of the 20th century. They have become an essential part of modern society, finding use in packaging, aerospace and automotive materials, electronic components, and many more applications. Their superior mechanical, physiochemical, and thermal properties have facilitated extensive research into these materials for numerous innovative commercial products.

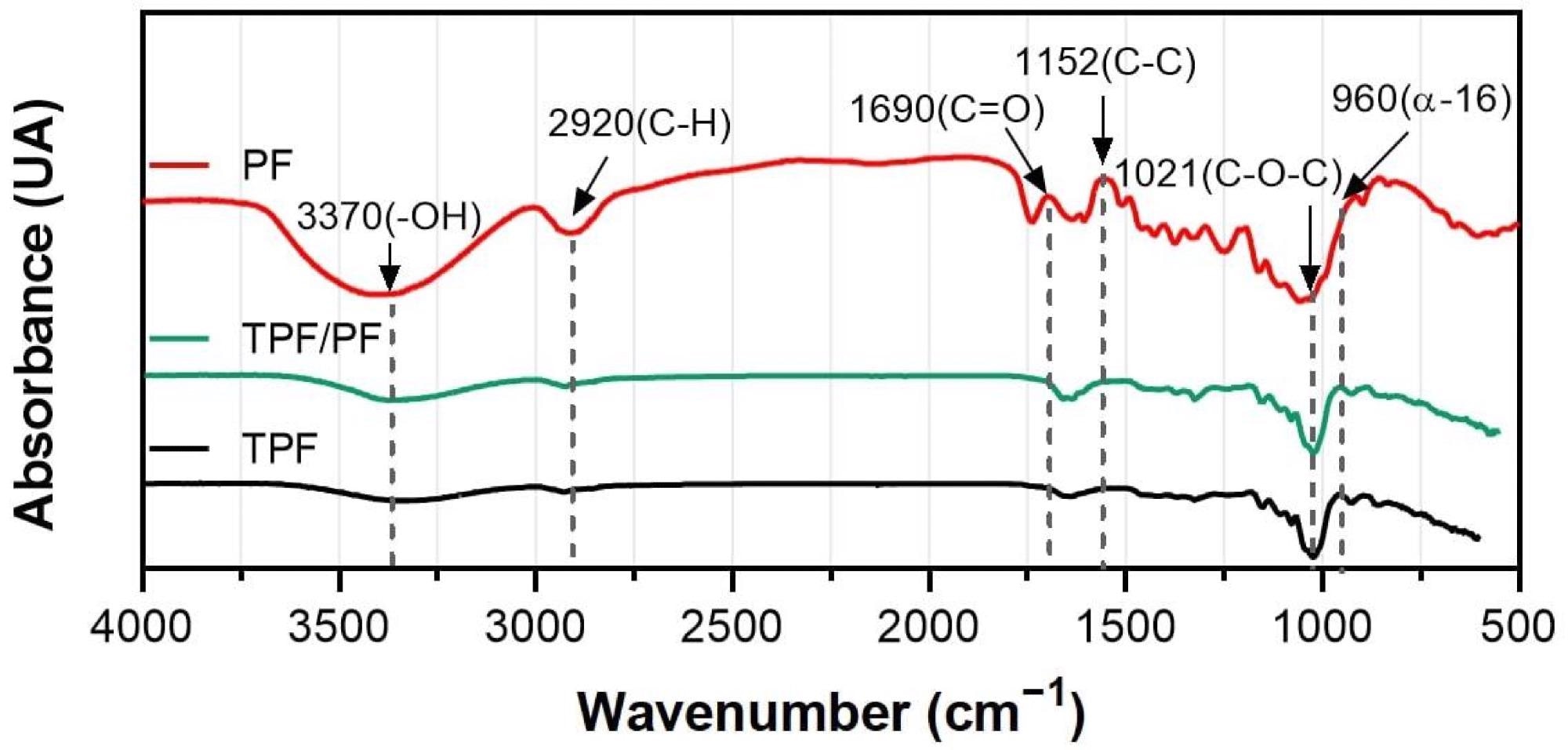

Fourier-transformed spectroscopy of the TPF, PF, and TPF/PF. Image Credit: Vanegas et al., Polymers

However, plastic manufacturing places a significant burden on both the environment and society. The plastics industry is responsible for a considerable proportion of the carbon emissions and waste produced globally, with polymers taking hundreds of years to degrade within the environment. Additionally, the production and disposal of conventional fossil-fuel-derived polymers leach toxic chemicals into the environment, where they accumulate. Microplastics and chemical by-products also enter the food chain, presenting a risk to human health.

Due to the well-recognized damage that conventional hydrocarbon-based plastics cause, research has focused in recent years on the production of biopolymers and biocomposite materials. Many different renewable, non-toxic, and carbon-neutral biomass sources for plastics have been explored by researchers across the world. To be commercially viable, biocomposites and bioplastics must display comparable properties to plastics conventionally produced from fossil fuel sources.

Studies have mainly focused on a few biomass sources for biocomposite plastics, including hemp, flax, bamboo, and sisal. The search for alternative biomass materials which can be used as fiber reinforcement to improve the physical and mechanical properties of biocomposites has been a key focus in bioplastics research over the past few years. Sources explored include plant species such as Prosopis juliflora and Abelomoschus escuelentus.

Using Starch as a Bio-polymer Material

Due to their ability to form viable bio-based polymers, organic macromolecules such as proteins and polysaccharides have been widely explored by researchers. These macromolecules are abundant in waste streams, but unfortunately at the moment most are sent to landfills or incinerated, wasting a potentially valuable sustainable source of materials for the bioplastics and bio-composite industry.

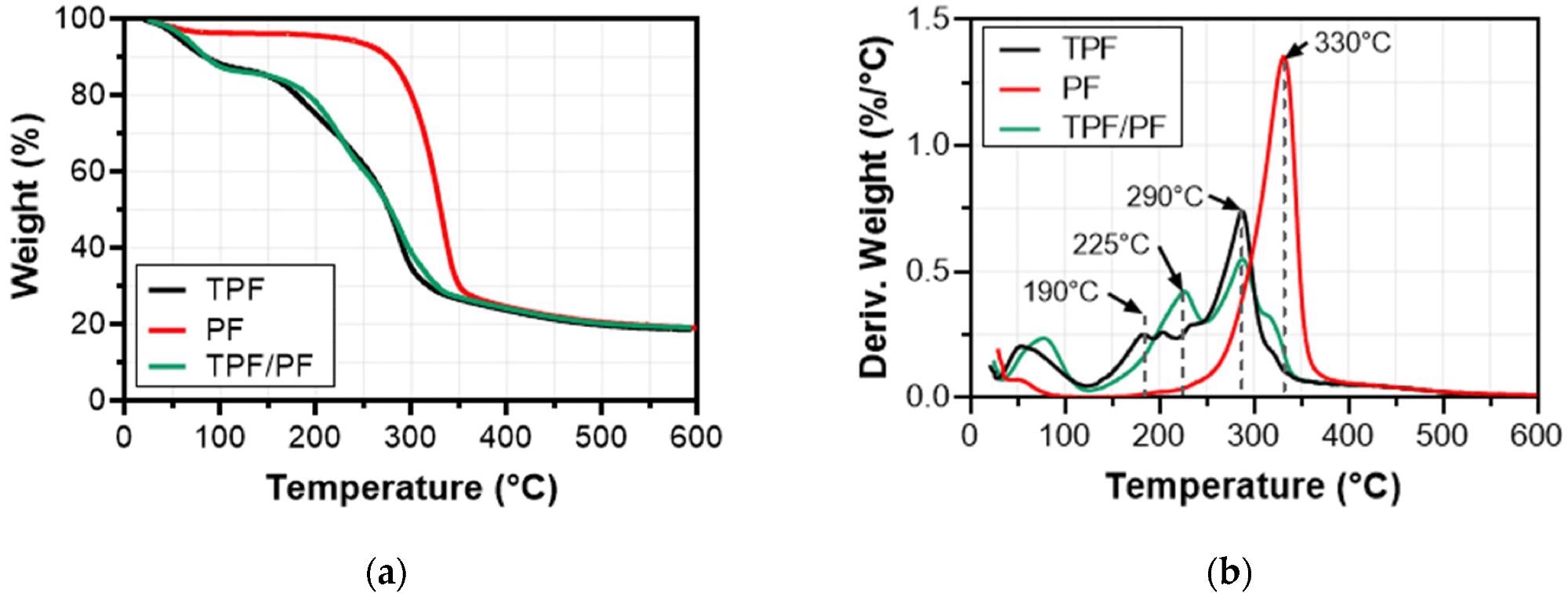

TGA (a) and DTGA (b) for TPF, PF, and TPF/PF. Image Credit: Vanegas et al., Polymers

Amongst these macromolecules, starch has emerged as an attractive candidate for this purpose in multiple studies. Starch has been used as the main component of biodegradable films and coatings, indicating that there is significant research interest in the fabrication of starch-based biopolymers for manufacturing biodegradable products. These biopolymers are also known as starch thermoplastics.

However, starch is commonly found in the edible part of plant material; therefore, to reduce the potential burden on the food industry by utilizing valuable crops for purposes other than food production, fruit-peel waste flour has been proposed as an alternative source of starch for the bio-polymers industry. Along with starch, these flours contain other macromolecules including other polysaccharides, lipids, proteins, and fibers.

The growing interest in using starch-based polymers which include natural fiber reinforcement has led to the possibility of creating value-added products using agro-industrial waste materials, which significantly improves the circularity of the food industry alongside reducing emissions, waste, and pollution from the plastics industry.

The Study

Writing in Polymers, the team of Venegas et al. has presented a novel bio-composite film consisting of a thermoplastic banana flour matrix reinforced with plantain fibers. Bananas and plantains are solely used as a food crop, meaning that their harvesting and processing produce valuable waste materials such as peel, stems, and pseudostems that currently have no commercially viable industrial use, leading to their disposal in landfills and incinerators.

Studies of plantain for use as a source of starch for biopolymers have been conducted over the past decade, with the physical, morphological, thermal, and mechanical properties of plantain flour and starch-based biopolymer films thoroughly investigated by Pelisaari et al. in 2013. However, even though the use of organic fibers as reinforcement materials has been evaluated in current literature, their integration into starch-based biological matrices has not been extensively explored.

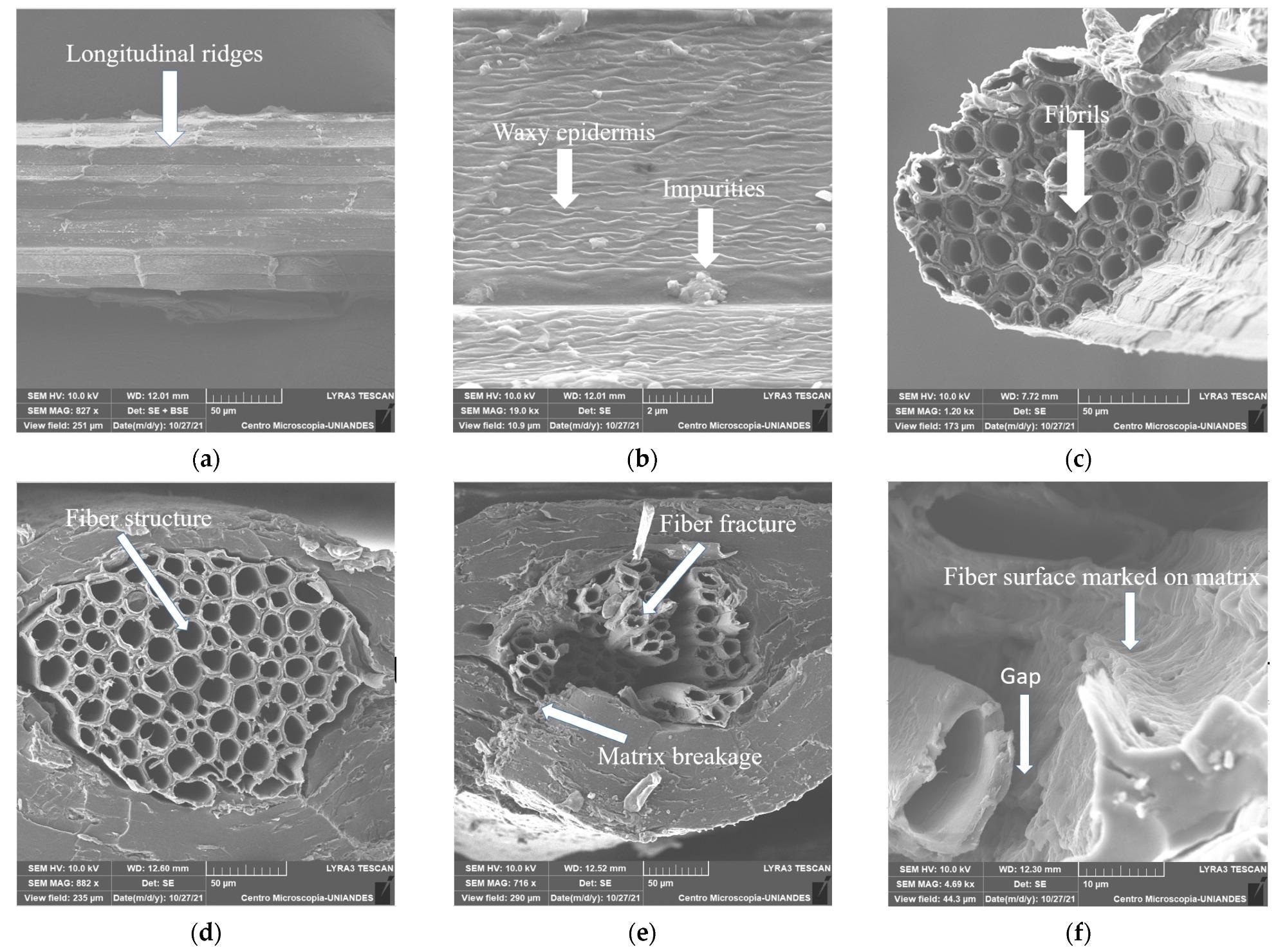

SEM images of PF at (a) ×827, (b) ×19,000, (c) ×1200 and TPF/PF (d) ×882, (e) ×716, (f) ×4690 longitudinal and cross sections. Image Credit: Vanegas et al., Polymers

Due to the possibility of valorizing waste streams from plantain and banana production, the team developed and categorized the novel bio-composite fiber-reinforced polymer presented in the research. Chemical composition analysis, TGA, SEM, and FTIR were used to analyze and categorize the thermal, chemical, morphological, and mechanical properties of thermoplastic banana flour, untreated plantain fibers, and the composite thermoplastic banana flour/plantain fiber biopolymer.

Analysis of the physical properties demonstrated a lightweight, biodegradable, and renewable material. Thermal analysis revealed that the thermoplastic degrades at lower temperatures than the reinforcing plantain fibers, and thus determines the temperature used for processing. The low lignin and high cellulose contents of the plantain fibers were revealed by spectral and chemical composition analysis, indicating their suitability as reinforcing materials.

Mechanical tests demonstrated enhanced tensile properties in the composite materials. Young’s modulus was improved by 1196%, whilst tensile strength showed a 345% improvement. Moreover, SEM revealed superior mechanical interlocking and bonding between the two components of the bio-composite material.

The results of the study have demonstrated a potentially attractive source of bio-composite reinforced biopolymers, with superior physical, mechanical, morphological, and thermal properties. Moreover, the material is sustainable and biodegradable and valorizes waste streams from the cultivation, harvesting, and processing of bananas and plantains, which improves the circularity of the food industry.

Further Reading

Vanegas et al. (2022) Development and Characterization of Plantain (Musa paradisiaca) Flour-Based Biopolymer Films Reinforced with Plantain Fibers [online] Polymers 14(4)748 | mdpi.com. Available at: https://www.mdpi.com/2073-4360/14/4/748

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.