As implausible as it sounds, a tooth could have a major role to play in the clean energy future of the world.

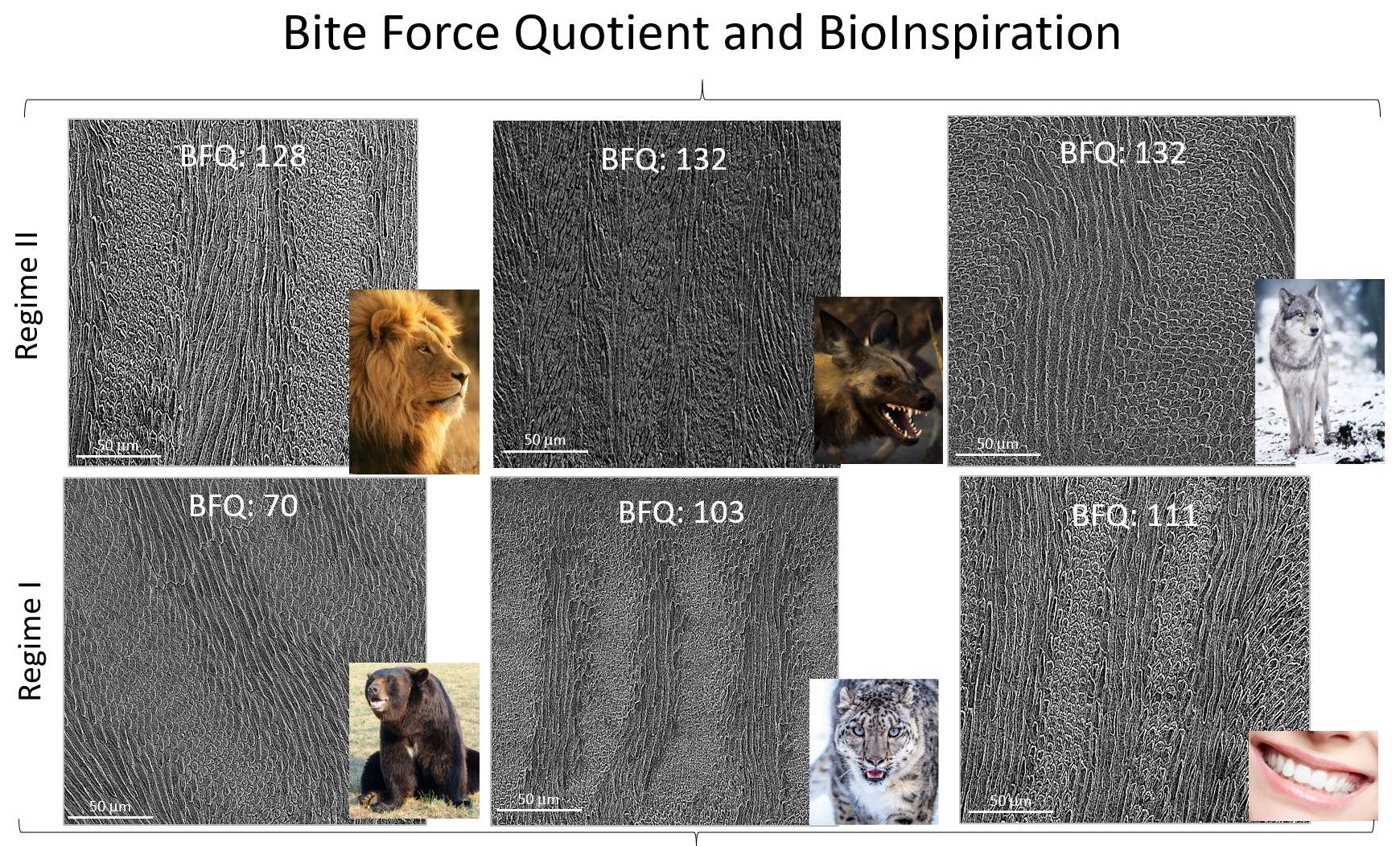

Imaging of the biting force of several animals’ enamel. Image Credit: Idaho National Laboratory.

Imaging of the biting force of several animals’ enamel. Image Credit: Idaho National Laboratory.

As dental enamel has distinctive properties that make it rigid as well as resilient, it has a variety of valuable applications besides chewing and biting. No artificial material possesses these essential innate qualities to the same level. Developing materials with some of those qualities could have a major effect on both national security and clean energy.

Many biological tissues have interesting and distinct properties, but we’re specifically exploring enamel because of its unique combination of strength and toughness.

Carli Marsico, Intern and Graduate Fellow, Idaho National Laboratory, DOE Office of Science

A prestigious fellowship was awarded by the DOE Office of Science to Marsico so that the Idaho National Laboratory (INL) intern could carry on the research, which is critical to both clean energy and national security, two core mission areas for INL.

Marsico’s interest in investigating approaches to reinforce monolithic ceramics originated in their application as body armor for army personnel. Before her internship at INL, she had been inquisitive about the distinctive properties of biological tissues and aimed to comprehend how they might be beneficial in the defense industry. However, this is far from the only groundbreaking result for this study.

The INL researchers are also keen to find out how tougher ceramics could decrease costs across the clean energy industry. As these ceramics are perfect for high-temperature surroundings, they are frequently used for environmental barrier coatings and other turbine components. Presently, these turbine components must be “overdesigned” with reinforcements, due to the brittle structure of the ceramics.

Tough and Strong: The Qualities of a Tooth

In the materials science domain, strength defines a material’s rigidity and ability to withstand deformation. Toughness indicates its ability to endure disastrous failures, such as breaking or cracking under pressure.

The synthetic material most similar to dental enamel is a monolithic ceramic, which refers to any ceramics made from only one material. They are reliable for use in high-temperature applications, which make them valuable in the automotive, electrical and electronics, power, and defense industries.

Carli Marsico, Intern and Graduate Fellow, Idaho National Laboratory, DOE Office of Science

Monolithic ceramics are robust and effortlessly resist deformation, but they are also brittle rather than tough. If it falls, it will easily shatter.

Inside the Tooth: Leveraging State-of-the-Art Imaging Techniques

To imitate the toughness and strength of dental enamel, and eventually apply it to monolithic ceramics, scientists must comprehend how enamel comprises these properties. This understanding necessitates high-quality imaging capabilities. This has been the foundation of Marsico’s study since she started working with INL’s Modeling and Simulation scientist Donna Guillen.

The structure of dental enamel does not lend itself well to the current three-dimensional imaging methods that we have. Our research proposal establishes a way around that—essentially, we’re taking two-dimensional images of dental enamel and transferring them into three-dimensional volumes.

Carli Marsico, Intern and Graduate Fellow, Idaho National Laboratory, DOE Office of Science

To positively move forward with this planned methodology, Marsico and the INL team were required to corroborate it — in this case, via a synchrotron experiment. Synchrotrons are large machines that speed up electrons matching nearly the speed of light, causing them to deflect through magnetic fields and form a very bright light.

That bright light enters the dental enamel sample, passing through it fully and, akin to X-Ray imaging, forming an image of the enamel’s interior.

In 2021, the researchers applied the same synchrotron process for the experiment with animal teeth. Examining animal teeth allows Marsico and Guillen to comprehend the distinctive roles and arrangements of some of the enamel characteristics that appeal to them most. Then, they will develop better computational models to rebuild these characteristics and apply them to artificial materials.

“Different animals’ dental enamel is optimized for specific functions,” Marsico said. “For example, an herbivore’s enamel is designed for slow grinding, whereas a carnivore’s enamel might be more conducive to biting and tearing and might also be more shock resistant.”

Where Do We Go from Here? Clean Energy and Defense Applications

Once we understand what makes dental enamel so tough, we can hopefully mimic those properties when engineering monolithic ceramics. This will allow for lighter weight, lower cost manufacturing of items such as turbine parts and body armor, thereby strengthening both our nation’s security and clean energy future.

Carli Marsico, Intern and Graduate Fellow, Idaho National Laboratory, DOE Office of Science