In a recent study published in the journal MethodsX, researchers from Taiwan developed a novel method to synthesize naturally soft and colored polyester through esterification polymerization of collagen peptides extracted from fish scale waste.

Study: A method for the process of collagen modified polyester from fish scales waste. Image Credit: mycteria/Shutterstock.com

The collagen peptide formed a triple helix structure containing glycine, proline, and hydroxyproline, which resulted in enhanced hydrophilicity, antistatic properties, ductility, durability, strength, and resistance to wrinkle and shrink, which are comparable to that of traditional polyethylene terephthalate (PET) fibers. Moreover, its champaign like natural color and soft texture makes it suitable for dye-less skin-friendly valuable textile fabric.

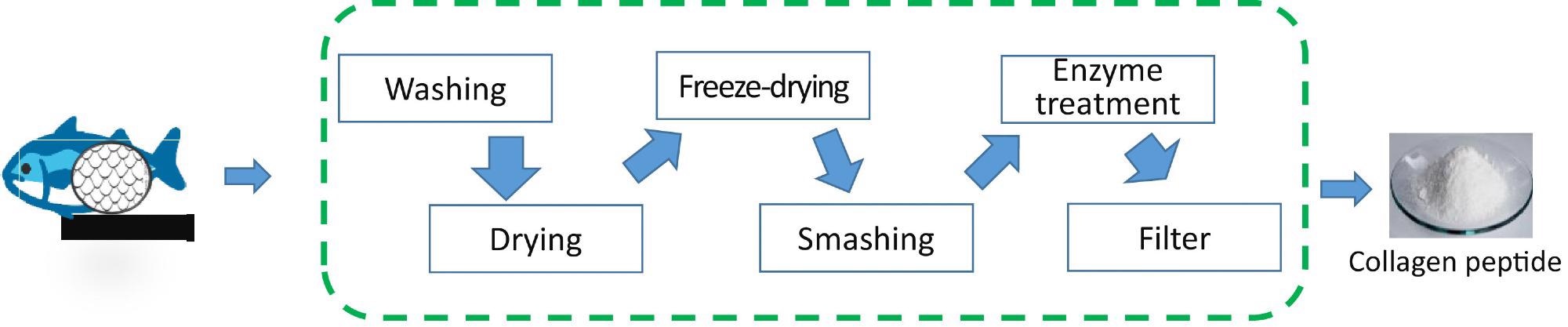

The process of Collagen peptide from fish scales. Image Credit: Hou, E et al., MethodsX

Background

The most commonly used thermoplastic polyester is PET ([C10H8O4]n), which is the fourth most produced synthetic polymer and contributes to 18% of the total polymer production of the world. It is composed of more than 85%, ethylene glycol, and terephthalic acid. PET-based textiles are lightweight, durable, and wrinkle-free. However, its airtightness, harder texture, and poor hygroscopicity make it an uncomfortable textile material in pure form. Thus, polyesters are mostly blended with other fabrics or interwoven in textile products.

Meanwhile, collagen peptides are essential protein supplements for human beings, which can only be obtained from animals but cannot be obtained from plants. Aquatic animals such as fish have a high content of collagen peptides in their skin and scales.

Many coastal regions have a large number of fishing hubs that produce aquatic waste materials. Moreover, collagen extracted from fish scales are fat-, prion-, and antibiotic-free contrary to collagens extracted from land animals. Three α-chains of collagen consisting of glycine, proline, and hydroxyproline can be assembled into complex hierarchical fibers for use in textile materials.

Extraction of Collagen Peptides from Fish Scales

Firstly, researchers in this study extracted the collagen peptide from the fish scales in powder form. The fish scales were thoroughly washed with deionized water and dried and cooled under vacuum conditions. Later, they were crushed and ground to fine powder form, followed by treatment with enzymes. Finally, the hydrolyzed liquid was segregated from the solid mineral base via centrifugal filtration and further dried to obtain the collagen peptide in powder form.

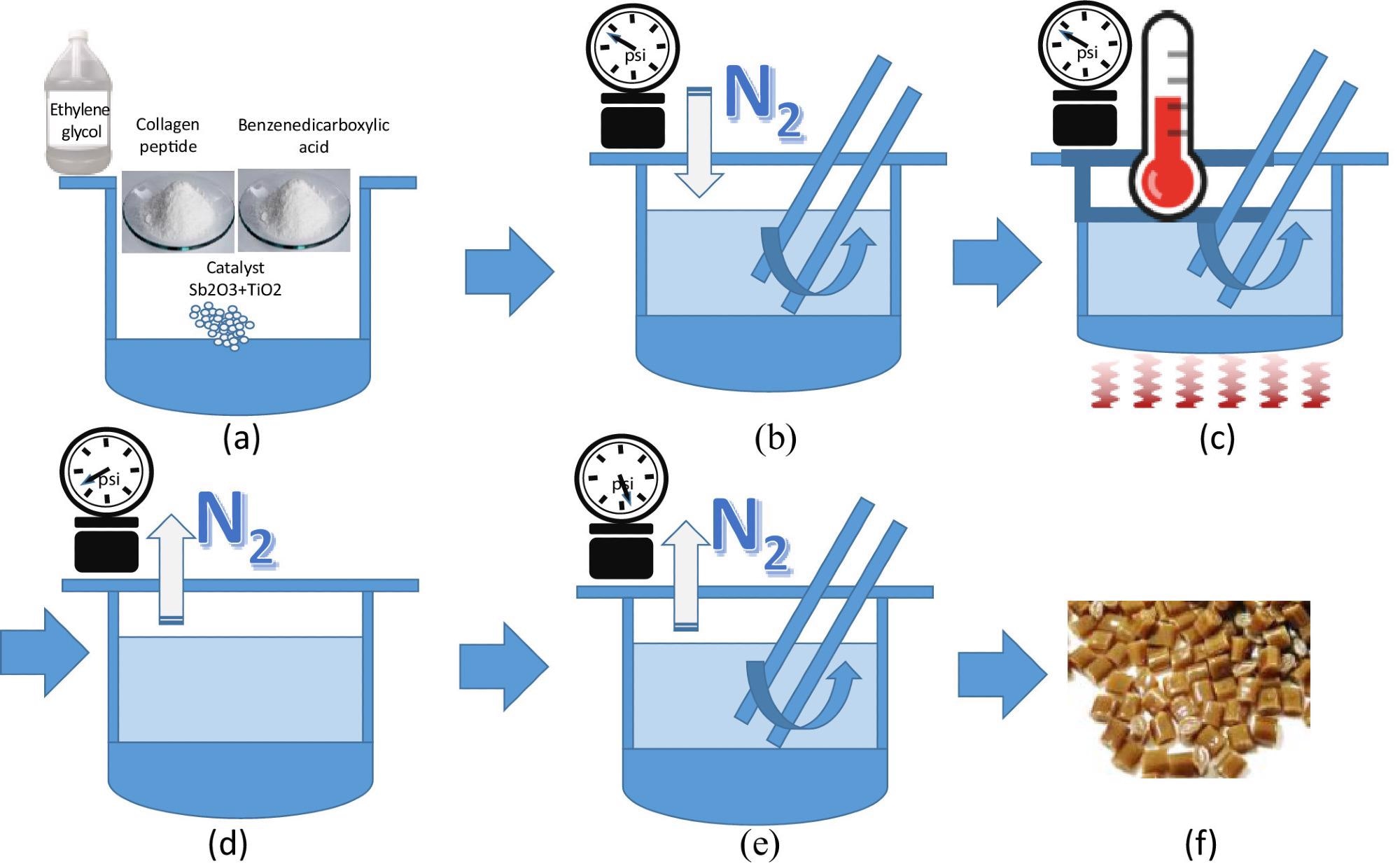

The stages of supramolecular polymerization. (a) mixing of raw materials and catalysts, (b) Introducing nitrogen into the container and stirring the mixture, (c) Heating the mixture for executing an esterification reaction from 210°C to 270°C, (d) Decreasing the pressure to 20 torr in the container for a polycondensation reaction, (e) Decreasing the pressure to 3 torr in the container and forming copolyester material and (f) the produced bionic polyester pellets. The values of pressure are not limited thereto and can be changed in accordance with the needs. Image Credit: Hou, E et al., MethodsX

Esterification of Collagen Peptide into Polyester

The collagen peptide powder extracted from the fish scales was mixed with benzene dicarboxylic acid, ethylene glycol, and several catalysts. Benzene dicarboxylic acid can be pure terephthalic acid (TPA) or pure iso-phthalic acid (IPA), or a mixture of TPA and IPA. The catalyst was a mixture of antimony oxide (Sb2O3) and titanium oxide (TiO2) with a parts per million (ppm) concentration ratio in a range of (160-360):(0-60).

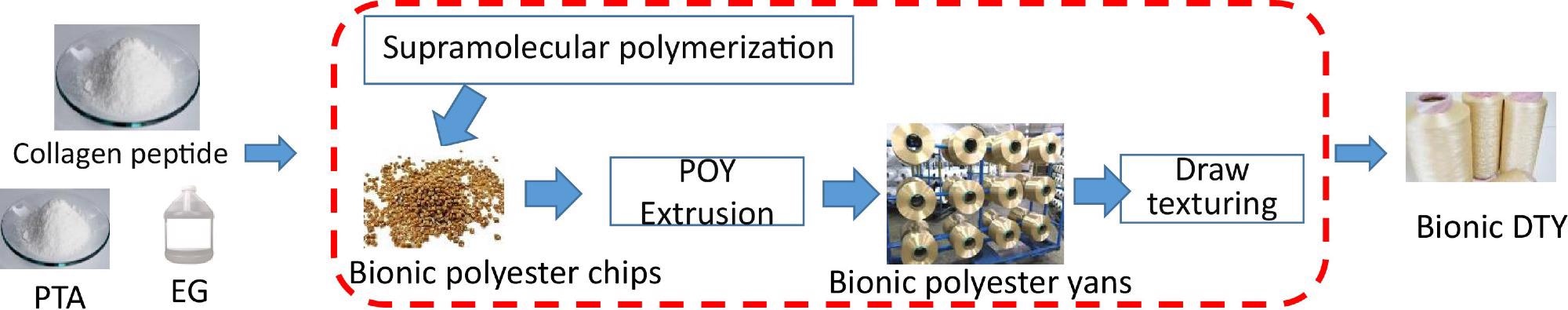

Subsequently, the mixture was melted at 210-270 ℃ temperature and 20 torr pressure into a syrup-like solution under a nitrogen atmosphere and poured into a spinneret. The solution was centrifugally forced through the tiny holes of the spinneret to form partially oriented yarns (POYs). After that, the collagen-modified POY was drawn to form drawn textured yarns (DTYs). Finally, the produced bionic DIY was used for the fabrication of textile products.

The process of producing collagen modified polyester materials. Image Credit: Hou, E et al., MethodsX

Conclusions

To summarize, the researchers of this study fabricated textile fabric from collagen peptides extracted from the fish scales. The prepared fabric had a natural champaign-like color and soft texture compared to the commercially available PET textiles. Moreover, the triple helix α-chain hierarchical structure with improved strength, hydrophilicity, and the same wrinkle-free behavior makes it more appealing. Bio-waste recycling also adds a premium value to the finished product and, at the same time, contributes to the circular economy.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Hou, E., Huang, C., Lee, Y., Han, Y., Chu, H., A method for the process of collagen modified polyester from fish scales waste, MethodsX, 2022, 101636, ISSN 2215-0161, https://www.sciencedirect.com/science/article/pii/S2215016122000218