Writing in the journal Polymers, a team of scientists from China has published a study investigating the development of improved strippable films for radioactive decontamination purposes. The team has extensively evaluated the proposed materials in their research, demonstrating that they are highly suitable for removing radioactivity from multiple surfaces.

Study: A Sprayable and Visible Light Rapid-Cured Strippable Film for Surface Radioactive Decontamination. Image credit: Andreas Prott/Shutterstock.com

The Dangers of Nuclear Power

Nuclear power plants have existed since the mid-1950s, with the first power plant connected to the electricity grid in Russia. Whilst they produce vast amounts of power which can satisfy the energy needs of entire populations, the danger of nuclear accidents has facilitated the need for stringent safety protocols in their design and operation.

Over the past eighty years, there have been several highly publicized nuclear disasters, including Chernobyl, Three Mile Island, Windscale, and Fukushima. Accidents cause massive amounts of radioactive materials to enter the environment where it causes pollution of land and groundwater supplies, as well as severe health problems in people. Radioactivity is persistent, remaining in the environment for many years.

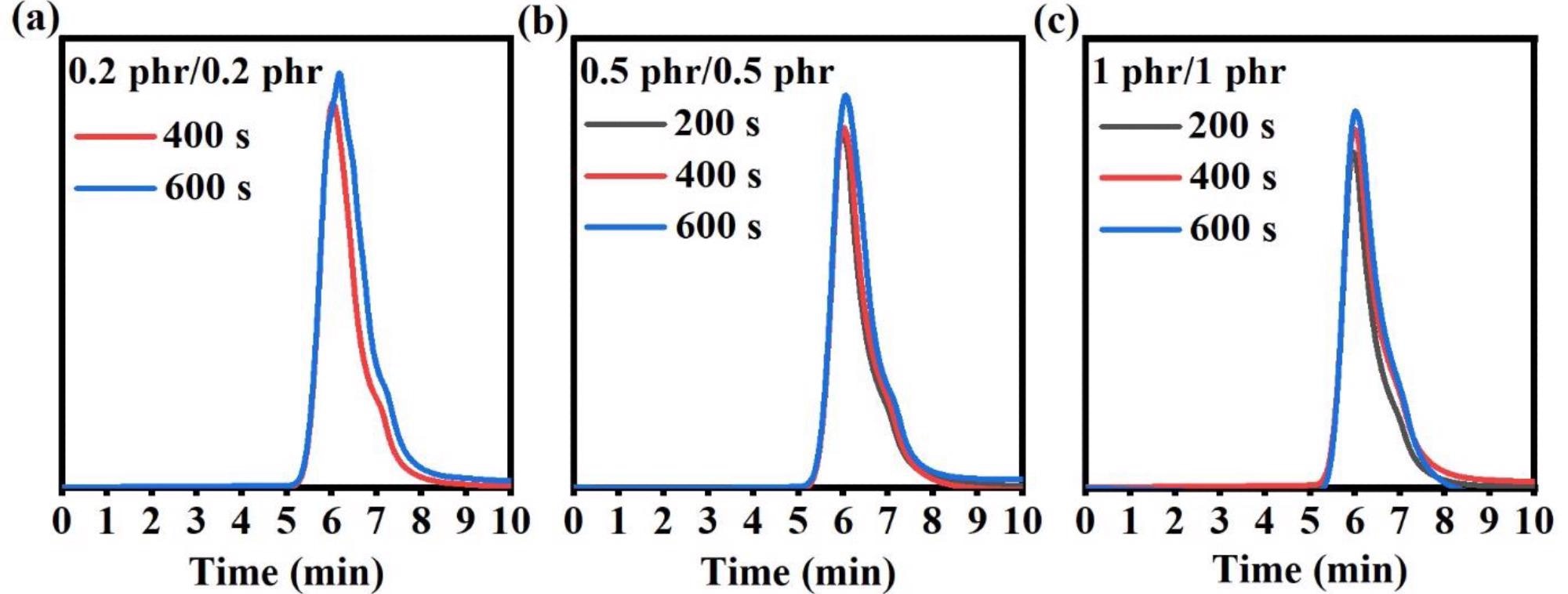

GPC spectra of PTBA prepared with different loadings of CQ/EDB: (a) 0.2 phr/0.2 phr; (b) 0.5 phr/0.5 phr; (c) 1 phr/1 phr, under the household LED panel light irradiation for different times. Image Credit: Zhang, H et al., Polymers

Conventional Decontamination Methods

Over the years, many methods have been employed to decontaminate nuclear accident sites. These methods include high-pressure water washing, ultrasound, electrochemical methods, mechanical grinding, as well as specially formulated gels and foams. Local populations are evacuated to safe areas whilst decontamination efforts are ongoing.

However, these methods are not always effective at removing adequate levels of radiation from contaminated sites. Their application can be limited by cost, logistics, secondary pollutants, the type of contaminant present, and several other factors.

Strippable Films

Amongst recently proposed radioactivity decontamination methods, strippable films have been widely explored for their advantages in terms of cost, ease of application, low waste generation after their use, and their compatibility with multiple surfaces such as glass, metals, ceramics, and cement.

Several strippable decontamination films are available on the market already. These are ALARA 1146, TLC Free, Isotron Radblock, DeconGel 1108, and InstaCote CC Wet/CC Strip. These materials have been widely evaluated for decontamination performance by organizations such as the EPA. They use different materials in their manufacture, and overall, they display good performance and high decontamination factors with different curing times.

Despite the success of these commercial formulations, there is always room for performance improvement. Recent research has concentrated on novel solutions to provide better decontamination materials. Smart materials which indicate the presence of contaminants via color change have been recently developed, as well as fragmentable films which can be easily removed with automatic machinery, reducing the need for human operators, and improving safety.

The main materials used in strippable decontamination films are acrylic copolymers and PVA. PVA-based hydrogels which contain 137CS adsorbent components have recently been developed by the Korean Atomic Energy Research Institute. These hydrogels possess reversible crosslinking characteristics, and the adsorbent components can be separated to reduce radioactive waste volume. However, the hydrogel can only be removed by washing the surface with water.

Issues with strippable films include the use of substantial amounts of solvents, volatile organic compound emissions, utilization of copious amounts of resources such as water, and long drying times. These issues can limit their large-scale application and present sustainability, safety, cost, and environmental issues. UV curable strippable films have been widely explored to overcome these issues but present their own challenges, such as eye damage which can be caused by UV use. Developing films that can be cured using visible light would circumvent this issue.

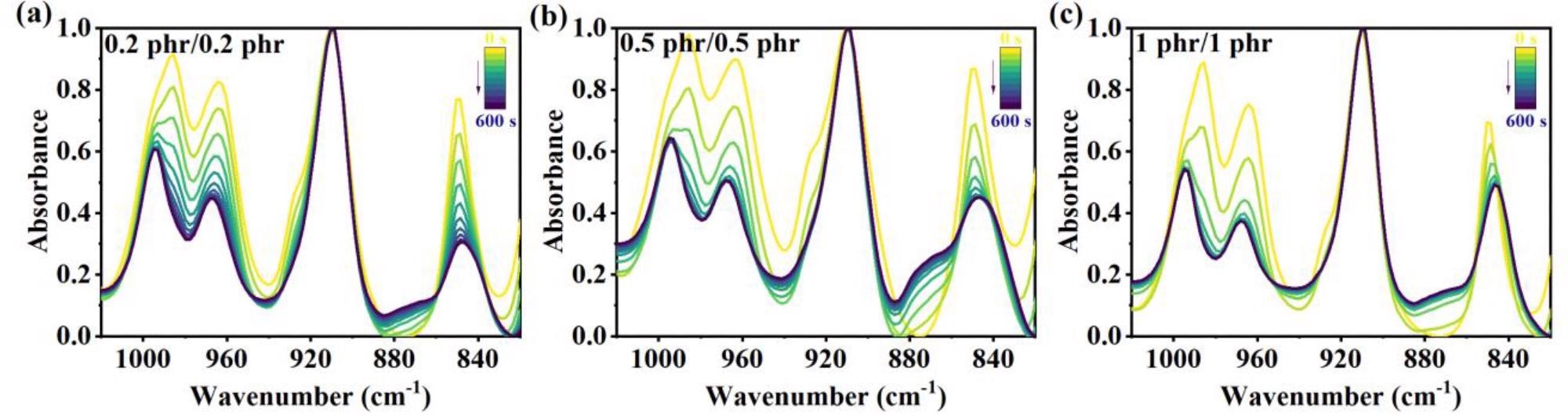

The FTIR spectra ranging from 1020 to 820 cm−1 for liquid polybutadiene/tert-butyl acrylate (LPB/TBA) solution during irradiation (household LED panel light, 50 mW/cm2) in the presence of different loadings of CQ/EDB photoinitiating systems: (a) 0.2 phr/0.2 phr; (b) 0.5 phr/0.5 phr; (c) 1 phr/1 phr, the spectra recorded per 60 s. Image Credit: Zhang, H et al., Polymers

The Research

Writing in the journal Polymers, the authors have presented a novel strategy to prepare sprayable and strippable films. The simple strategy explored in the research utilizes commercially available chemicals. Solvent-free strippable films which exhibit rubber elasticity were obtained by the researchers. Camphorquinone/ethyl 4-dimetyhlyaminobenzoate was used as a photo initiating system, and tert-butyl acrylate and liquid polybutadiene were used as monomers.

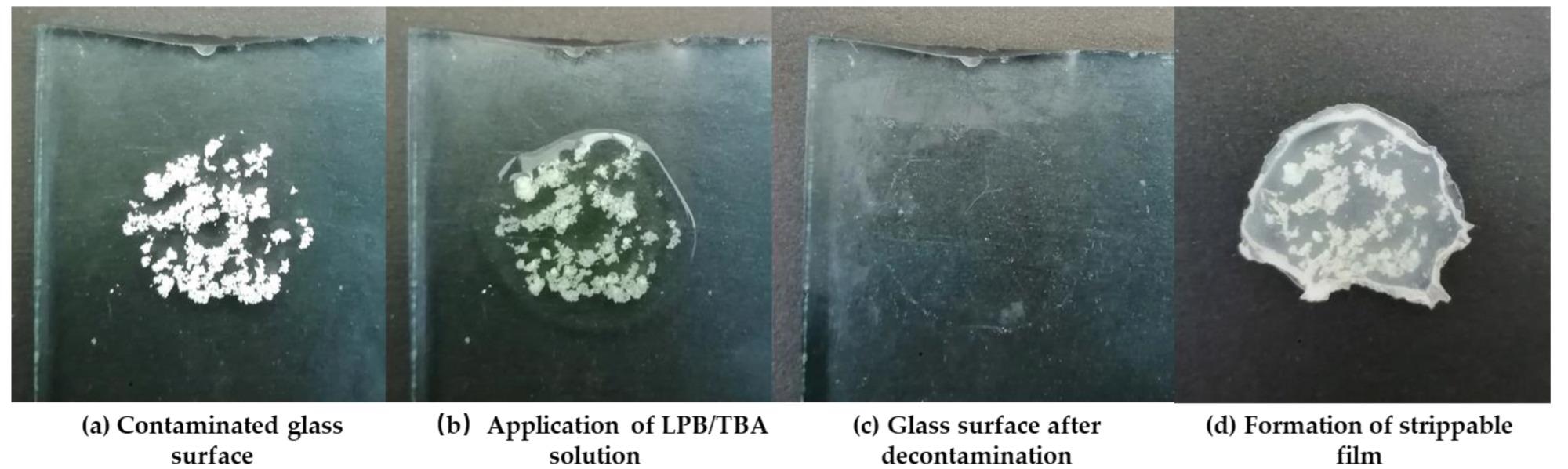

The prepared sprayable and strippable films were cured in under 540 seconds under visible light irradiation, improving both time and safety issues. The film can be cured using both household LED lights and natural sunlight. The films possess superior mechanical properties, high decontamination performance, and superior strippability.

Decontamination procedure of strippable film on glass surface. Image Credit: Zhang, H et al., Polymers

The results of testing demonstrated 98.1% decontamination efficiency for removing CsCl on glass surfaces, 94.3% on ceramic surfaces, and 97.6% on metal surfaces. Viscosity was low, at 0.15 Paꞏs (making it suitable for spraying), and the volatile organic compound content was extremely low, at 12.7 ± 0.7%, making the film extremely environmentally friendly. Additionally, the material also displayed excellent tensile strength and elongation at break.

Moreover, the authors have stated that the sprayable and strippable film presented in the research is suitable for industrial application due to its simplicity, and use of commercially available raw materials. The danger of radioactivity from nuclear accidents facilitates the need for developing improved solutions, and this novel visible-light reactive sprayable and strippable film is an interesting addition to the body of research in the area.

Further Reading

Zhang, H et al. (2022) A Sprayable and Visible Light Rapid-Cured Strippable Film for Surface Radioactive Decontamination [online] Polymers 14(5) 1008 | mdpi.com. Available at: https://www.mdpi.com/2073-4360/14/5/1008

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.