By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.Apr 8 2022

By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.Apr 8 2022In a review recently published in the open-access journal Materials, researchers presented the role of washing polyester fabrics in increasing microplastics in wastewater.

Study: Microplastics in Wastewater by Washing Polyester Fabrics. Image Credit: chayanuphol/Shutterstock.com

Background

Microplastics have emerged as one of the most serious environmental threats today, prompting fears that levels will continue to climb in the near future. When plastic breaks down into microscopic fragments owing to mechanical or photochemical processes, micro/nanoparticles are formed. Microplastics are ubiquitous, and they have a strong inclination to interact with the ecosystem, posing a threat to biogenic fauna and flora.

As a result, even before research studies on the long-term hazards and repercussions are accessible, the slow release and usage of microplastics, which occurs directly in the fiber production process, must be significantly curtailed and be part of a global campaign.

Microfibres detected in laundry effluent, wastewater and seawater. Image Credit: Šaravanja, A et al., Materials

About the Study

In this study, the authors discussed the most common causes of microplastic pollution in the environment and provided an overview of washable polyester materials. The impact of microplastics on the environment and human health was also discussed.

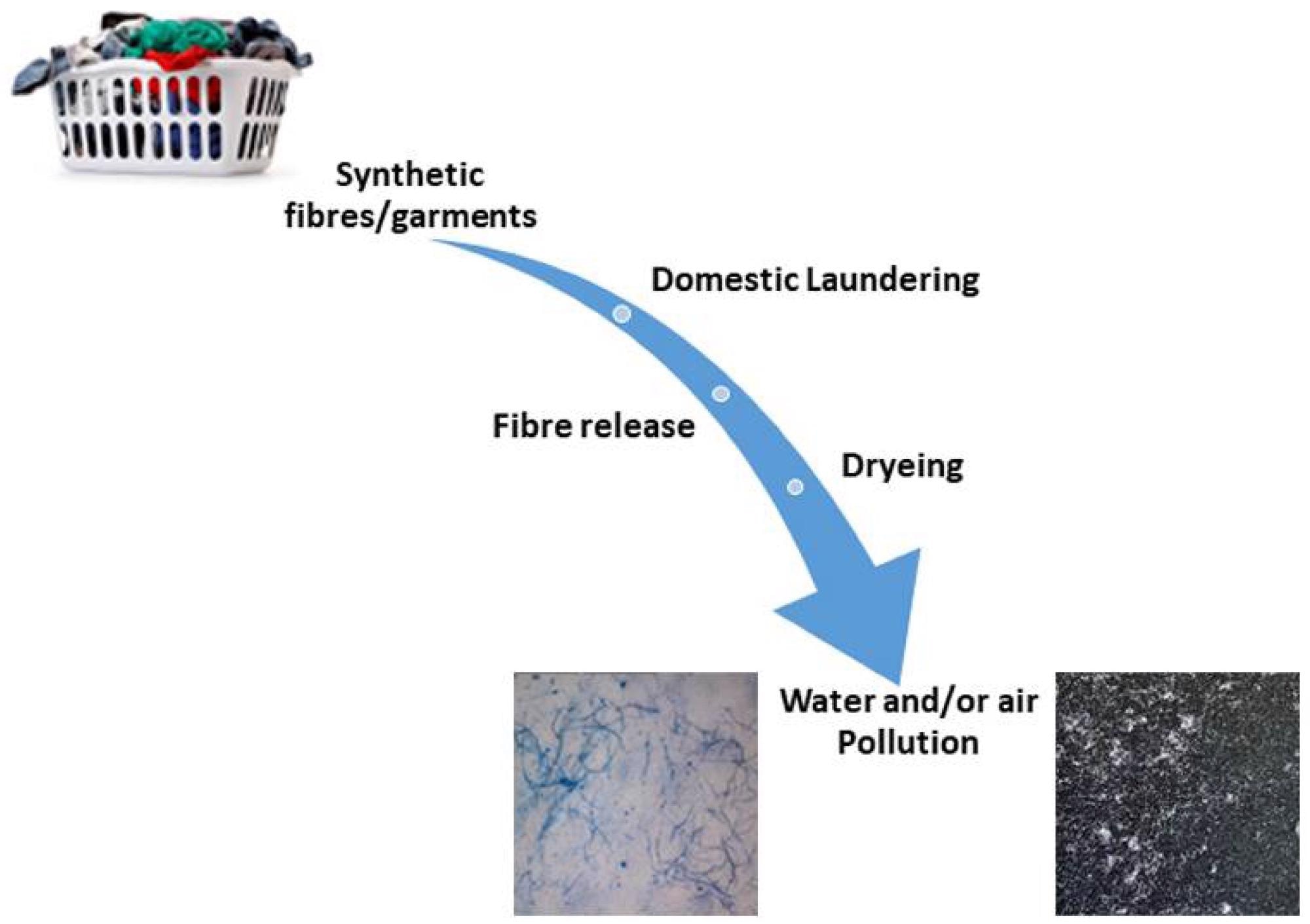

The researchers presented a detailed analysis of polyester (PET) and polyamide (PA) as two of the most widely used synthetic fibers, as they account for over 60% of total global fiber output. The need for synthetic textiles for clothing, carpets, and a range of other products was also discussed. The potential of synthetic fabrics to discharge microplastics into the environment during the production or washing process was illustrated.

The team evaluated the need to create as many programs as possible to monitor microplastics and their role in microplastic pollution prevention and management.

Observations

Comamonas Testosteroni, a type of biocatalyst cell, could break down PES and thereby minimize microplastic discharge. The diameter of PES was 7.30 µm at the start of the process and after treatment in the alkaline medium, the diameter reduced to 1.58 µm, which promoted rapid degradation of PES by bacteria under alkaline degradation conditions, as well as biosorption, which facilitated the binding of the adsorbate and the adsorbent surface.

Microfibers that were accumulated could be easily removed by hand. Many studies demonstrated that the ball absorbed roughly 35% of the total amount of fibers in each wash. The washed treated materials' test results revealed a considerable reduction in microfibers of up to 90% when compared to untreated fabrics, as well as a promising resistance to washing.

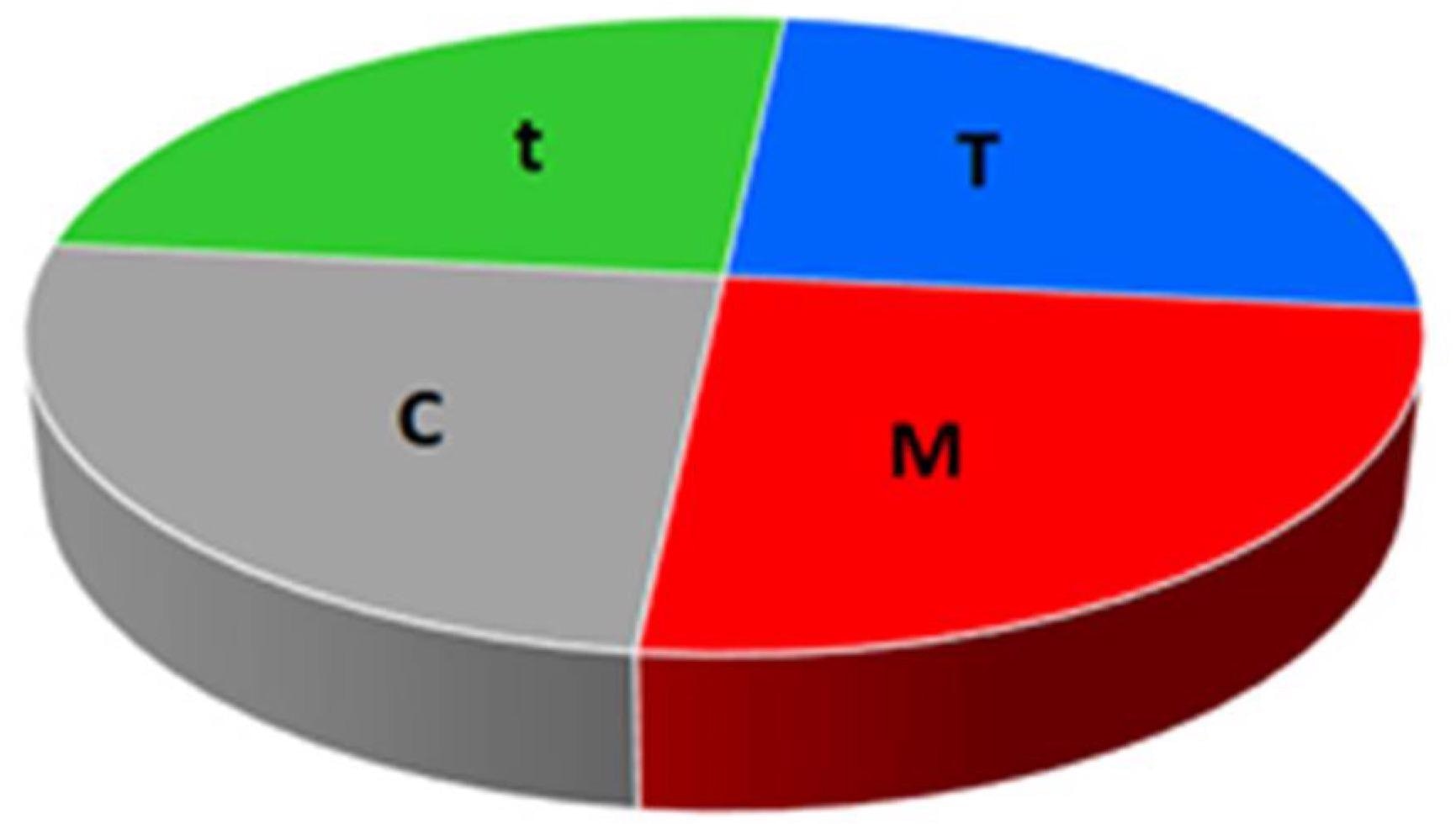

Washing factors according to Sinner’s cycle: t—time, T—temperature, M—mechanics, C—chemistry. Image Credit: Šaravanja, A et al., Materials

According to several studies, a human could swallow between 39,000 and 520,000 microplastics per year through food and beverages, with levels that were naturally varied by age and gender. With a 95% efficiency, microplastic particles with a diameter of up to 10 µm could be eliminated. Finland's yearly microfibre emissions were projected to be 154,000 kg (PES) and 411,000 kg (PES) (cotton). The average diameter of the released fiber during washing was 11.9 to 17.7 µm, and the length was 5.0 to 7.8 mm.

The results revealed that materials aged for 12 and 35 minutes at temperatures below 160°C exhibited no difference from untreated yarns. Materials processed at temperatures over 160°C but below 200°C lost strength below 1.11 cN/tex.

When polyester samples were aged at temperatures of 140°C and 160°C for 12 minutes and 35 minutes, there was essentially no difference in strength between the treated and untreated samples. However, as the temperature increased, the strength and hardness of the material decreased by around 5% at 200°C and 19% at 220°C, respectively. The strength of a sample aged at 220°C for 35 minutes was nearly 31% lower than the untreated polyester.

The microfiber shedding mode. Image Credit: Šaravanja, A et al., Materials

Conclusions

In conclusion, this study showed that many countries have yet to develop a comprehensive strategy for the biggest sources of microplastics in water, as well as ways to effectively clean them up. Several research initiatives have looked into the impact of microplastics on ultimate waste and the removal of microplastics in wastewater treatment plants at each step of the process. The authors emphasized that it's critical for the machines to be energy-efficient, cost-effective, and ecologically friendly in order to limit microplastic emissions as much as possible.

They mentioned that in terms of polyester and microplastics, the key goal is to make polyester with the best structural properties and transition to as many recycled products as possible. They determined that it's critical to employ the best agents for protecting the polymer's structure and preventing the release of microplastics during washing. According to the results, synthetic materials' washing and drying procedures must also be optimized, as they are market-relevant and unique. The authors believe that this interdisciplinary topic will remain significant in the future, with plenty of room for more research.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Šaravanja, A., Puši´c, T., Dekani´c, T., Microplastics in Wastewater by Washing Polyester Fabrics. Materials 15(7) 2683 (2022). https://www.mdpi.com/1996-1944/15/7/2683