In a bid to replace the harmful chemicals used in durable water repellent (DWR) textile coatings, a new research collaboration is developing a sustainable alternative made from biopolymers.

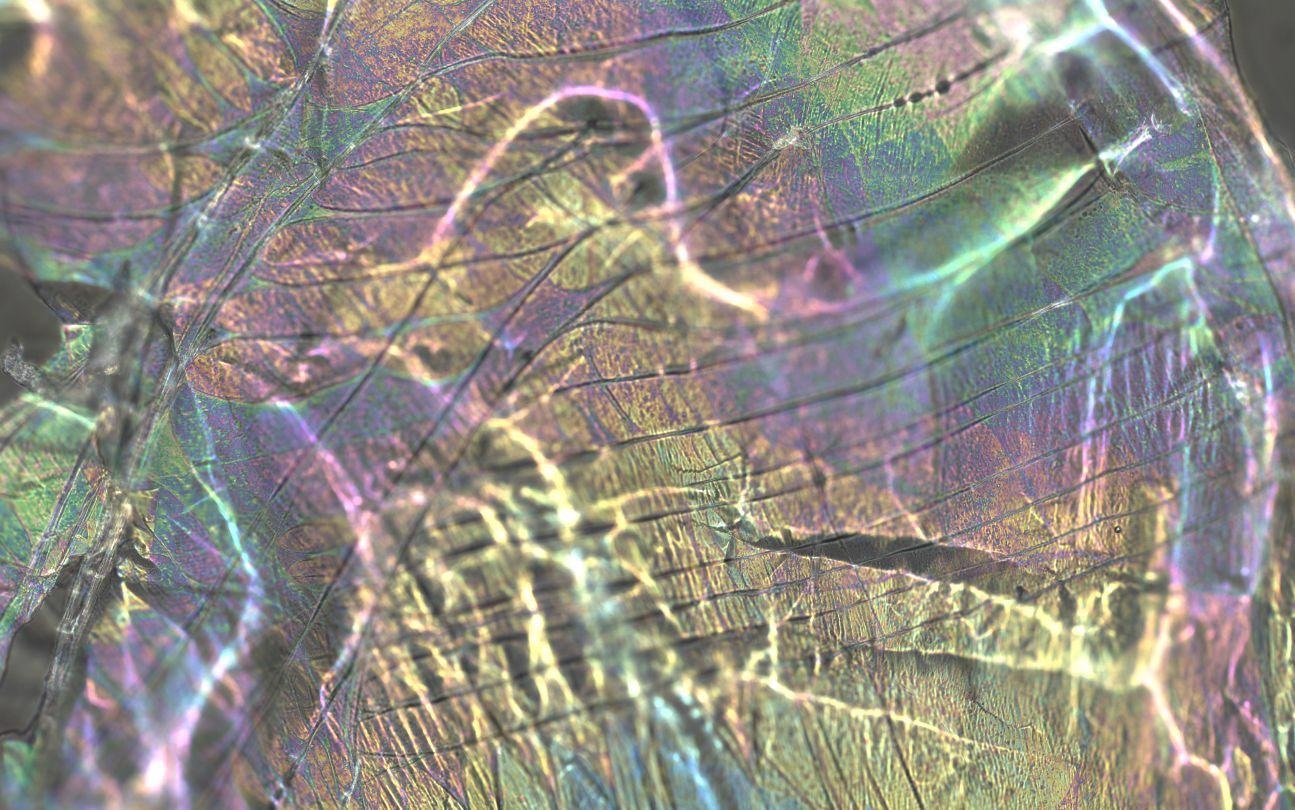

Raman image of Solitary Masked Bee nesting material. Image Credit: Innovative Manufacturing Cooperative Research Centre

Raman image of Solitary Masked Bee nesting material. Image Credit: Innovative Manufacturing Cooperative Research Centre

The Innovative Manufacturing Cooperative Research Centre (IMCRC) has granted New Zealand based biotechnology research company, Humble Bee Bio, and Deakin University $70,000 to develop and sample new textile coatings.

The 7-month project, worth a total of $566,000 cash and in-kind funding, will be based at Deakin’s Institute for Frontier Materials (IFM) and supported by the Australian National Fabrication Facility.

Veronica Harwood-Stevenson, Humble Bee Bio’s CEO and Founder, said the research collaboration would be instrumental to the success of the next stage of development for Humble Bee Bio’s novel biopolymer.

“By mimicking the properties of the solitary masked bee's cellophane-like nesting material, we have created a biopolymer that’s water-repellent and resistant to flames, high temperatures and strong chemicals,” she said.

“This research collaboration will enable Humble Bee Bio to take our proof of concept and develop a formulation and production method for sustainable DWR biopolymer coatings.

“Australia is poised to become an advanced biomanufacturing centre of the world, and we are thrilled to be part of building that success."

Professor Joselito Razal, Director of ARC Research Hub for Future Fibres at IFM, said the project reinforced Deakin’s commitment to re-designing materials for a circular economy.

“Deakin University will utilise its world class expertise and facilities in fibre and materials science to facilitate Humble Bee Bio’s vision of a sustainable Australian textile industry,” he said.

Dr Dylan Hegh, IFM’s Circular Economy Initiatives Manager and project lead, added that the research would provide Humblee Bee Bio with an advanced understanding of the novel material and its properties.

“In refining the formulation, this collaboration has the potential to uncover new and unforeseen applications for the biopolymer and catalyse further research and development into advanced biomanufacturing,” he said.

Dr Matthew Young, IMCRC’s Manufacturing Innovation Manager, said IMCRC was pleased to be supporting the industry-university research collaboration by co-funding the development of Humble Bee Bio’s biopolymer.

“Novel advanced materials are playing a crucial role in achieving a more sustainable future for Australia and the rest of the world,” he said.

“Once commercialised, Humble Bee Bio’s sustainable DWR coatings have the potential to bridge a significant gap that exists within the textiles industry today.”

“By uniting industries and research institutions, we create an ecosystem that drives innovation and commercialisation, generating significant opportunities in specialised, high-value manufacturing.”