Reviewed by Alex SmithMay 3 2022

Ruthenium atoms on a network of copper nanowires may be an important step toward transforming the international ammonia industry that also supports the environment.

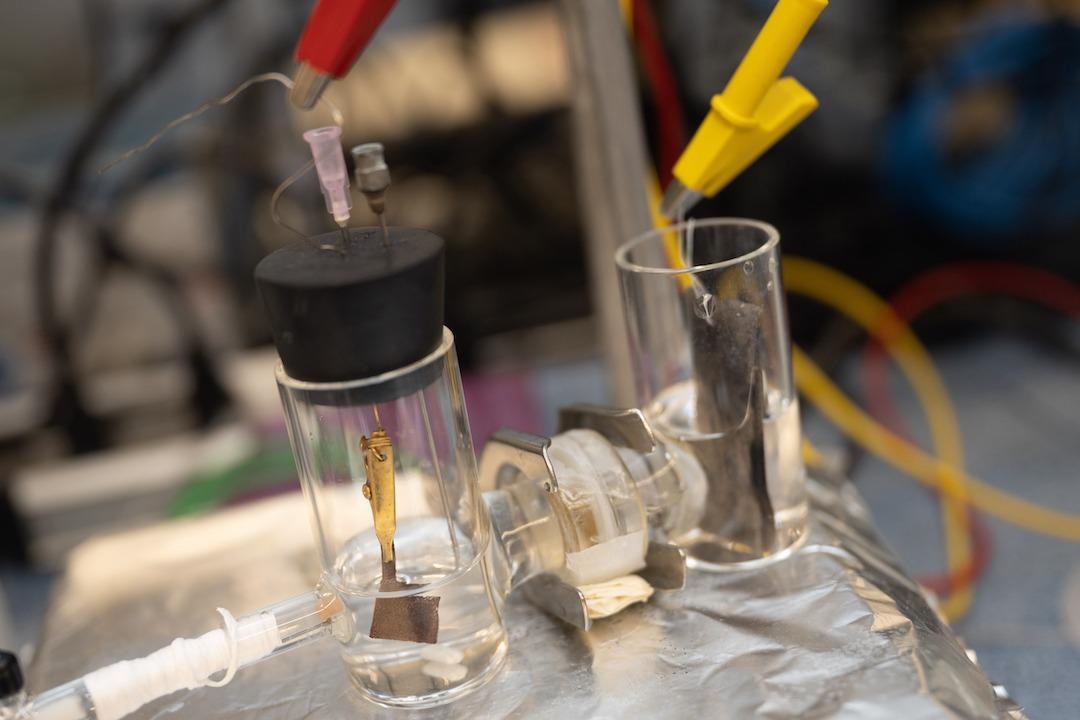

Rice University engineers have designed a catalyst of ruthenium atoms in a copper mesh to extract ammonia and fertilizer from wastewater. The process would also reduce carbon dioxide emissions from the traditional industrial production of ammonia. Image Credit: Jeff Fitlow.

Rice University engineers have designed a catalyst of ruthenium atoms in a copper mesh to extract ammonia and fertilizer from wastewater. The process would also reduce carbon dioxide emissions from the traditional industrial production of ammonia. Image Credit: Jeff Fitlow.

Researchers at Rice University’s George R. Brown School of Engineering, Pacific Northwest National Laboratory, and Arizona State University created the high-performance catalyst that is capable of, with almost 100% efficiency, extracting ammonia and solid ammonia — also known as fertilizer — from low quantities of nitrates that are extensive in polluted groundwater and industrial wastewater.

A study directed by Haotian Wang, Rice University’s chemical and biomolecular engineer, demonstrates that the process turns nitrate levels of 2,000 parts per million into ammonia, followed by an effective gas stripping process for ammonia product collection. The residual nitrogen contents following these treatments can be lowered to “drinkable” levels as stipulated by the World Health Organization.

We fulfilled a complete water denitrification process. With further water treatment on other contaminants, we can potentially turn industrial wastewater back to drinking water.

Feng-Yang Chen, Graduate Student and Study Lead Author, Rice University

Chen is one of three lead authors of the study that has been reported in the journal Nature Nanotechnology.

The research demonstrates a favorable substitute for efficient processes for an industry that relies upon an energy-concentrated process to create over 170 million tons of ammonia annually.

The scientists were aware from earlier studies that ruthenium atoms are excellent at catalyzing nitrate-abundant wastewater. Their twist, however, involved merging it with copper, which subdues the hydrogen evolution reaction, a process to create hydrogen from water that in this case is an unnecessary side effect.

We knew that ruthenium was a good metal candidate for nitrate reduction, but we also knew there was a big problem, that it could easily have a competing reaction, which is hydrogen evolution. When we applied current, a lot of the electrons would just go to hydrogen, not the product we want.

Feng-Yang Chen, Graduate Student and Study Lead Author, Rice University

“We borrowed a concept from other fields like carbon dioxide reduction, which uses copper to suppress hydrogen evolution,” added Wang. “Then we had to find a way to organically combine ruthenium and copper. It turns out that dispersing single ruthenium atoms into the copper matrix works the best.”

The researchers used density functional theory calculations to describe the reason for ruthenium atoms making the chemical path that links ammonia and nitrate easier to cross, according to the study’s co-corresponding author Christopher Muhich, an assistant professor of chemical engineering at Arizona State University.

When there is only ruthenium, the water gets in the way. When there is only copper, there isn’t enough water to provide hydrogen atoms. But on the single ruthenium sites water doesn’t compete as well, providing just enough hydrogen without taking up spots for nitrate to react.

Christopher Muhich, Study Co-Corresponding Author and Assistant Professor of Chemical Engineering, Arizona State University

The method works at ambient temperature and under ambient pressure, and at what the scientists termed an “industrial-relevant” nitrate reduction current of 1 amp per square centimeter, the amount of electricity required to heighten the catalysis rate. That should render it easy to expand, Chen stated.

I think this has big potential, but it’s been ignored because it’s been hard for previous studies to reach such a good current density while still maintaining good product selectivity, especially under low nitrate concentrations. But now we’re demonstrating just that. I’m confident we’ll have opportunities to push this process for industrial applications, especially because it doesn’t require big infrastructure.

Feng-Yang Chen, Graduate Student and Study Lead Author, Rice University

A crucial advantage of the method is the decrease of carbon dioxide emissions from the conventional industrial manufacture of ammonia. These are not insignificant amounts as they add up to 1.4% of the annual emissions worldwide, the scientists observed.

“While we understood that converting nitrate wastes to ammonia may not be able to fully replace the existing ammonia industry in the short term, we believe this process could make significant contributions to decentralized ammonia production, especially in places with high nitrate sources,” Wang said.

Together with the new research, Wang’s lab and that of Rice environmental engineer Pedro Alvarez, director of the Nanotechnology Enabled Water Treatment (NEWT) Center, recently published a paper in the Journal of Physical Chemistry C describing the application of cobalt-copper nanoparticles on a three-dimensional carbon fiber paper substrate as an efficient catalyst to produce ammonia from nitrate reduction. This inexpensive catalyst also demonstrated substantial promise for the denitrification of wastewater.

Co-lead authors of the Nature Nanotechnology paper are Rice University’s postdoctoral fellow Zhen-Yu Wu, and Srishti Gupta, a graduate student at Arizona State University.

Co-authors include graduate student Daniel Rivera of Arizona State; Sten Lambeets of the Pacific Northwest National Laboratory, Richland, Washington; research scientist Guanhui Gao, undergraduate Stephanie Pecaut, graduate students Jung Yoon Kim and Peng Zhu, and Yimo Han, an assistant professor of materials science and nanoengineering, at Rice University; Zou Finfrock, Hua Zhou and Wenqian Xu of Argonne National Laboratory, Lemont, Illinois; Debora Motta Meira and Graham King of Canadian Light Source, Saskatoon, Saskatchewan; and David Cullen of Oak Ridge National Laboratory, Oak Ridge, Tennessee.

Daniel Perea of the Pacific Northwest lab is the paper’s co-corresponding author. Wang is the William March Rice Trustee Chair and an assistant professor of chemical and biomolecular engineering.

The study was supported by the National Science Foundation Nanosystems Engineering Research Center for Nanotechnology Enabled Water Treatment (1449500) and the Welch Foundation (C-2051-20200401, C-2065-20210327).

Journal Reference:

Chen, F-Y., et al. (2022) Efficient conversion of low-concentration nitrate sources into ammonia on a Ru-dispersed Cu nanowire electrocatalyst. Nature Nanotechnology. doi.org/10.1038/s41565-022-01121-4.