By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.May 4 2022

By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.May 4 2022In an article recently published in the open-access journal Polymers, researchers discussed the utility of bio-based polymeric substrates on printed hybrid electronics.

Study: Bio-Based Polymeric Substrates for Printed Hybrid Electronics. Image Credit: Olena Yakobchuk/Shutterstock.com

Background

Flexible thin-film electronics are showing great promise in sensor, actuator, display, energy harvesting, and storage applications. One of the most widely used technologies for producing flexible electronics is screen printing. Because of their excellent conductivity, metallic particle inks are commonly utilized in screen printing. The majority of printed electronics substrate materials are now made from non-renewable fossil raw materials.

The increased use of electronic equipment around the world will result in environmental concerns at the end of their life cycle. Biopolymers that are biodegradable or compostable can provide an alternate end-of-life solution.

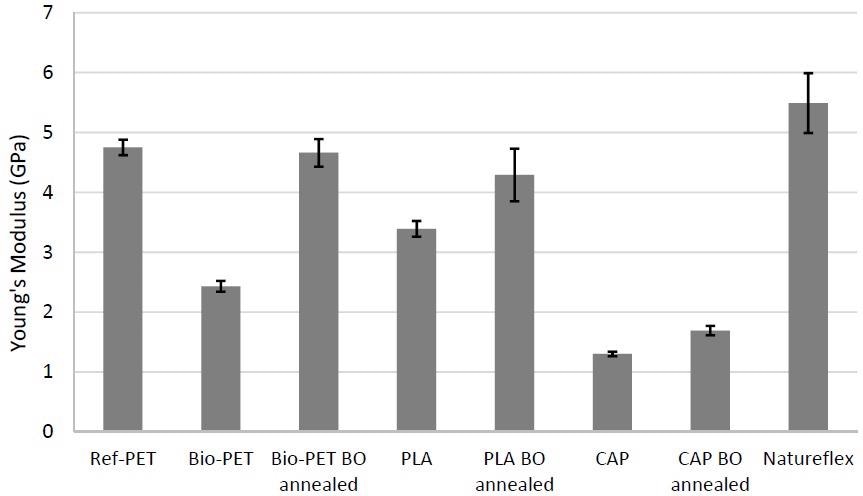

Young’s modulus values for film materials. Image Credit: Bahadoran, A et al., Polymers

Poly(ethylene terephthalate) (PET) is now also available as a partially bio-based resin (bio-PET), which contains 30% bio-based ethylene glycol and has a lower carbon footprint than entirely fossil-based grades. Poly(lactic acid) (PLA) is the most widely produced bioplastic and has already found use in a variety of applications. Given that cellulose esters are among the earliest biopolymers, they have been commercially important polymers since the 18th century. Regenerated cellulose, also known as CellophaneTM, is another cellulose-based substrate with a transparent plastic-like appearance but no thermoplasticity.

About the Study

In this study, the authors discussed the utility of renewable plastic materials in the screen-printing of conductive silver patterns sheet-to-sheet (S2S). Biaxially orientated (BO) bio-based PET (Bio-PET BO), poly(lactic acid) (PLA BO), cellulose acetate propionate (CAP BO), NatureFlexTM (Natureflex), and regenerated cellulose film were the utilized materials.

The researchers investigated the performance of various bio-based materials in the screen-printing process. The major goal was to develop more environmentally friendly substrate film materials for printed electronics applications without sacrificing performance. To generate thinner films with an orientated microstructure, cast films were oriented. Each material's orientation characteristics were tuned to produce the highest possible orientation ratio without tearing the film. Simultaneous biaxial stretching was performed, and differential scanning calorimetry (DSC) was used to investigate the transition temperatures and crystallinities of cast films.

The team used an optical profilometer to determine the film thickness, and an ultraviolet-visible-near infrared (UV-Vis-NIR) spectrophotometer was used to assess the optical transmission. A white light interferometer in vertical scanning interferometry (VSI) mode was used to quantify the surface roughness.

Root-mean-squared roughness (Rq) was estimated by fitting the root-mean-squared data from the surface profile with the mean surface level, and total roughness height (Rt) was computed from the peak-to-valley discrepancies. Scanning electron microscopy (SEM) pictures of cross-sections of the S2S screen-printed polymer films were acquired to investigate adhesion between the silver paste and the film surface.

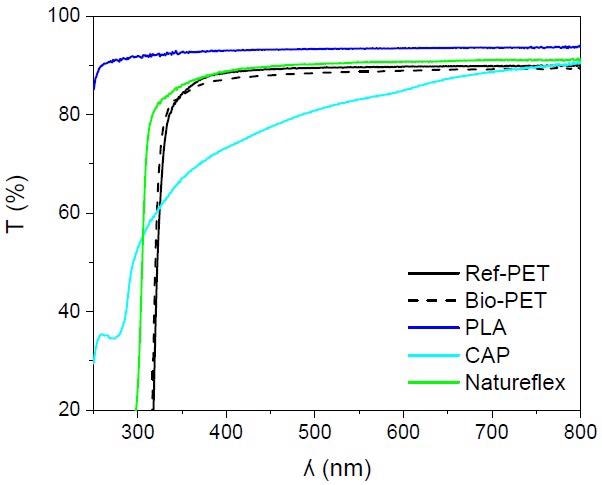

Optical transmission (T) of the Ref-PET, Bio-PET, PLA, CAP and Natureflex films versus wavelength (λ). Image Credit: Bahadoran, A et al., Polymers

Observations

The results revealed that bio-based materials could perform as well as or better than commercial fossil PET film, i.e., Ref-PET, even at lower printing temperatures than the standard 120 °C. In addition, the surface properties and optical transmission of the material were equivalent to those of the reference material. PLA films had greater optical transmission than commercial PET films made from fossil fuels. The compatibility of surface chemistries also promoted the use of bio-derived substrates in hybrid and printed electronics.

Due to more regular and compact structures in the printed patterns, screen-printed silver patterns on the Natureflex and CAP films had 11% and 18% lower resistance values than conventional PET film. The contact between the substrate and screen-printed silver was better with the Natureflex and CAP films. The dimensional changes in the CAP and Natureflex films were lower during the printing process than in the Bio-PET and PLA films, which indicated improved heat stability. Thermal stability during the process of printing had a major impact on the final ink layer structure creation.

The results demonstrated that surface energies alone were insufficient to predict the electrical behavior of new substrates. The thermal stability and surface qualities of bio-based substrates could be improved through film orientation and annealing. Importantly, the utilization of bio-based substrates was supported by strong electrical performance. The biaxially oriented Bio-PET and PLA films showed similar stiffness and tensile strength to commercial PET films in terms of mechanical performance.

Screen-printed hybrid-integrated LED foil. Image Credit: Bahadoran, A et al., Polymers

Conclusions

In conclusion, this study elucidated how well different types of bio-based polymer substrates worked with printed hybrid electronics. Strain-induced crystallization was used to create an orientated microstructure and better heat stability in laboratory-scale fabricated films. The authors encouraged the use of bio-derived substrate materials in flexible electronics, particularly biaxially oriented CAP, without compromising the performance and quality of the film and printed electronics structures. They emphasized that biaxially oriented PLA and Bio-PET films could perform well in applications that need tensile strength, stiffness, and optical clarity.

Silver ink had good printability on all renewable-based substrates and printed pattern resistance comparable to Ref-PET. The creation of the printed pattern to the cellulose-based substrates, Natureflex and CAP BO, was excellent, with 10 to 18% lower resistance than Ref-PET and the least transverse and machine direction deviation among the bio-based substrates in the S2S printing method. The authors believe that the findings of this study will open up new applications for renewable-based substrates as well as possibly biodegradable solutions made possible by the regenerated cellulose film and PLA.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Bahadoran, A., Liu, Q., Ramakrishna, S., et al. Bio-Based Polymeric Substrates for Printed Hybrid Electronics. Polymers 14(9) 1863 (2022). https://www.mdpi.com/2073-4360/14/9/1863