By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.May 4 2022

By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.May 4 2022In an article recently published in the open-access journal Sustainability, researchers discussed the development of a battery-free and long-term sustainable powertrain for hydrogen fuel cell city transit buses.

Study: A Battery-Free Sustainable Powertrain Solution for Hydrogen Fuel Cell City Transit Bus Application. Image Credit: Mikbiz/Shutterstock.com

Background

To combat global warming, Europe’s (EU) energy transition and sustainable development policies have set a goal of zero greenhouse gas emissions by 2050. One of the primary initiatives in the EU strategy's transport sector is to replace conventional internal combustion engine (ICE) vehicles with electric vehicles (EV), which will cut CO2 and other GHG emissions.

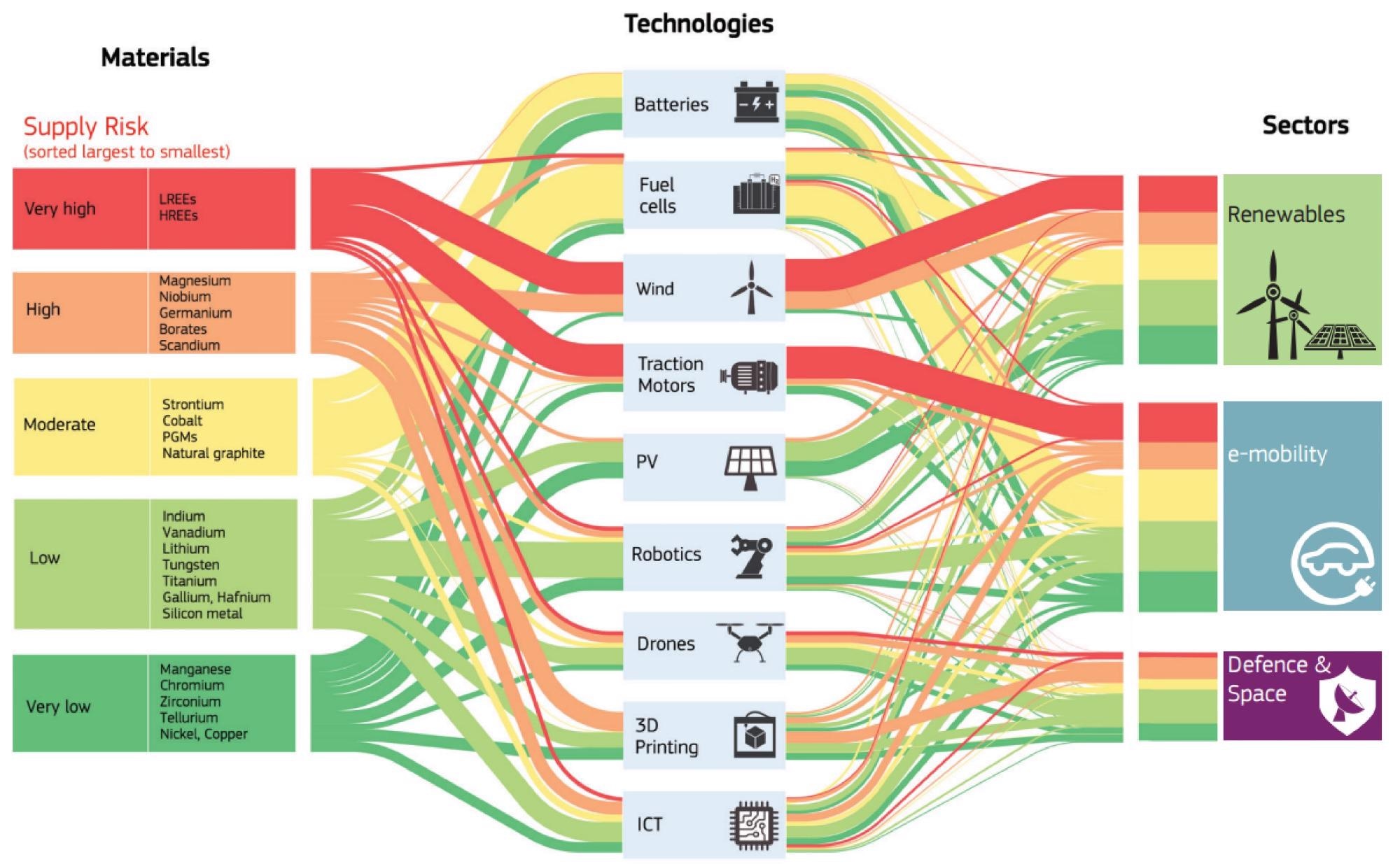

Raw materials used in key technologies for the relevant technology fields, and their related supply risk. Image Credit: Fabri, G et al., Sustainability

Battery electric vehicles (BEV) and hybrid electric vehicles (HEV) both use electrochemical batteries to store electric energy onboard at the moment. Hydrogen-powered (by fuel cell) vehicles (HFCVs) are a technological option for overcoming the limitations of BEVs while maintaining zero local emissions. Flywheel energy storage systems (FESS) can store energy as kinetic energy as an alternative to electrochemical batteries.

High-speed FESS is a new, ecologically friendly technology that is on the rise. Alternatives such as rare earth (RE) free or reduced RE motor technologies are gaining traction, with significant advancements in induction motor and synchronous reluctance motor technology.

About the Study

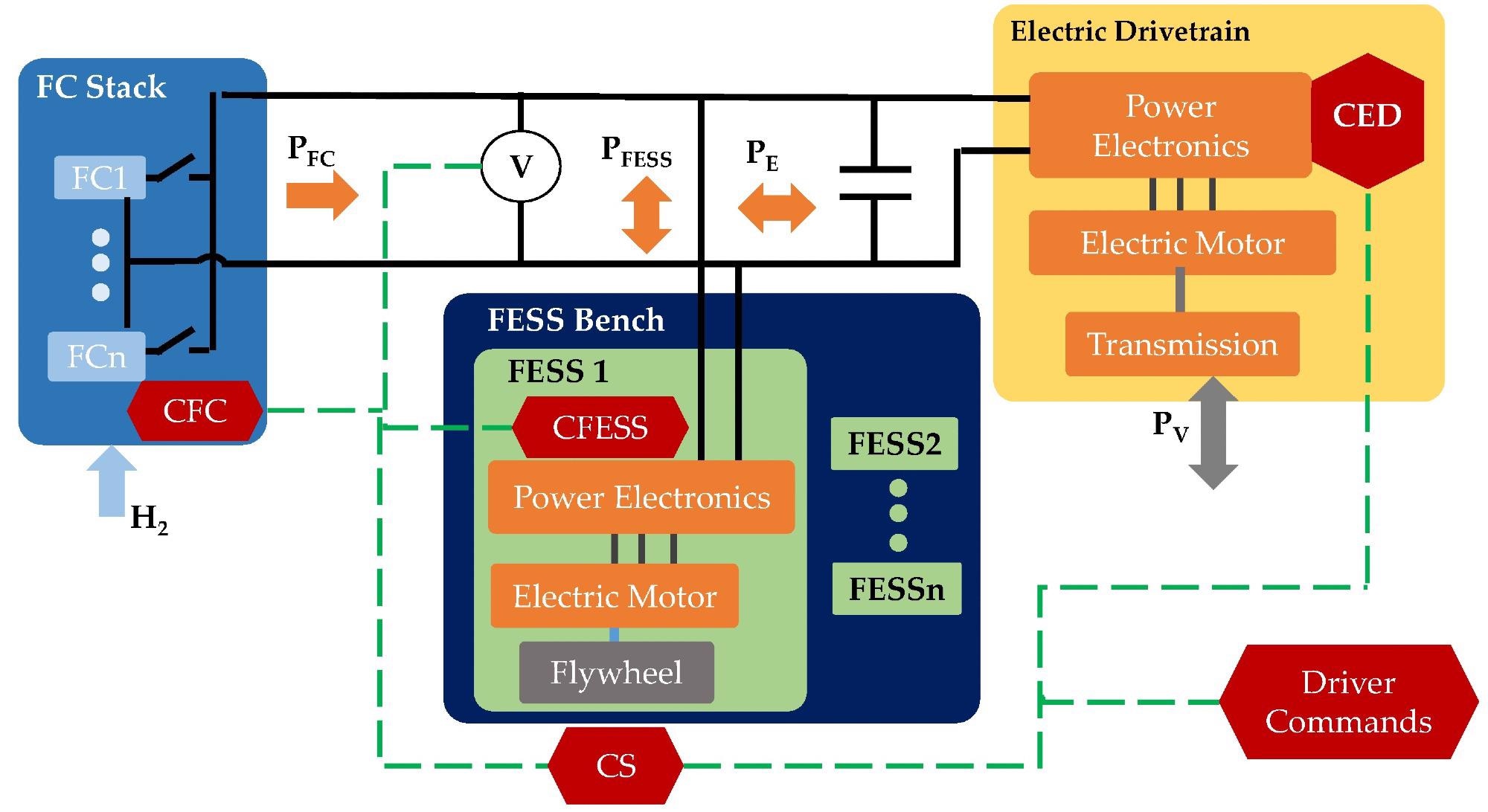

In this study, the authors described a sustainable electric powertrain for a transit city bus that included an electrochemical battery-free power unit made up of a hydrogen fuel cell stack and a high-speed flywheel-based kinetic energy storage system. To achieve a more sustainable vehicle architecture with the restricted use of crucial raw materials, a rare-earth-free high-efficiency motor technology was used.

An appropriate dynamic energetic model of the entire vehicle powertrain was constructed to evaluate the feasibility of the traction system and the associated energy management control technique. The model included losses characterization of the main components of the powertrain as a function of load using experimental tests and literature data.

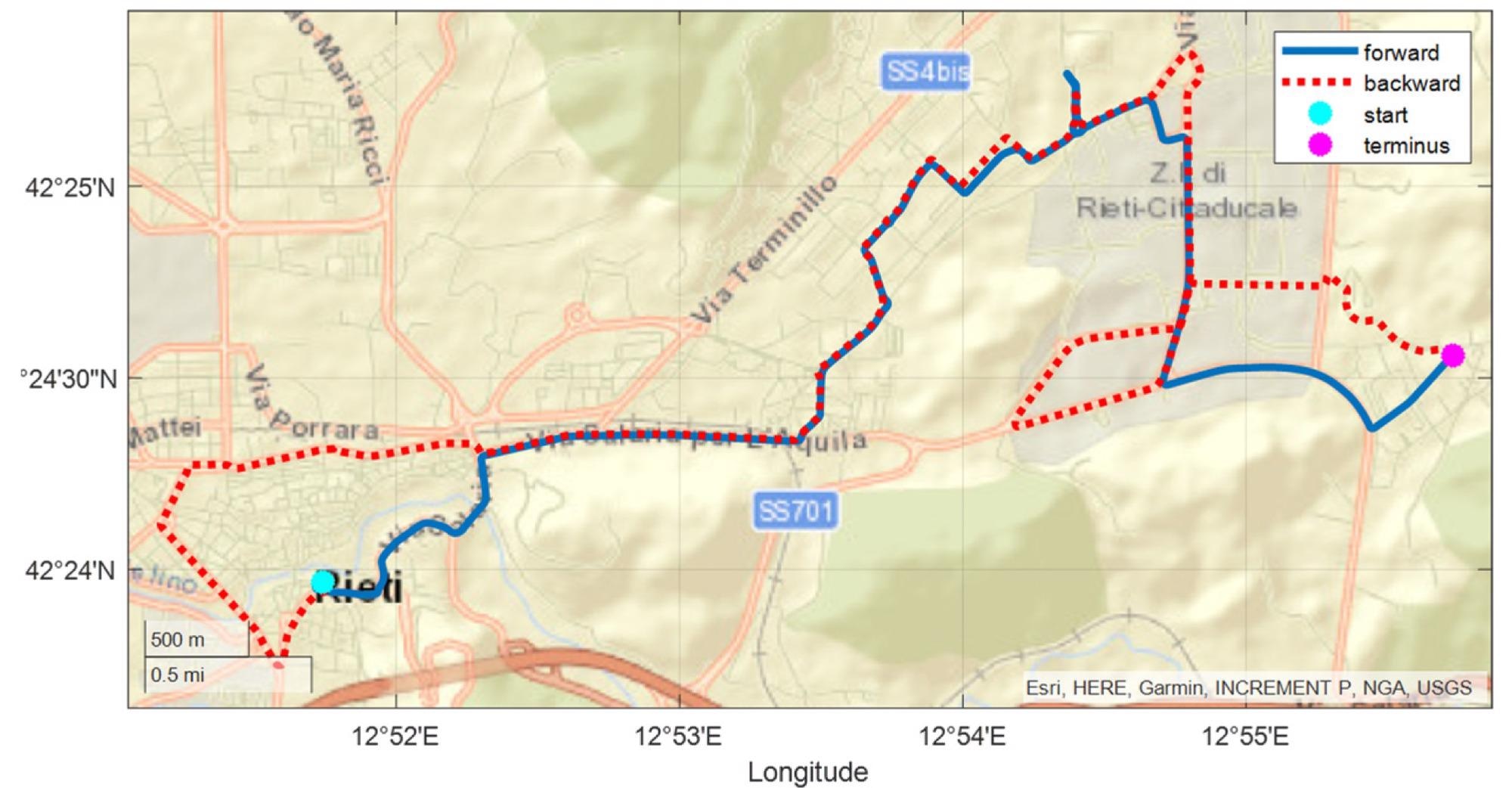

The team assessed the proposed solution's performance by the simulation of a vehicle mission on an urban path in real-world traffic situations. Considerations of the traction system's effectiveness were examined. A more sustainable architecture was offered, which considered battery-free powertrain architecture as well as the adoption of RE-free motor technologies in both traction and FESS motors. The efficiency map of each powertrain component was used and the effect of vehicle auxiliary loads on energy usage was investigated.

The researchers demonstrated the system architecture, the suggested hybrid power unit, and the modeling approach. A case study was also described, which included the driving cycle, vehicle definition, and path topography. The hybrid vehicle configuration was shown, as well as a revolutionary powertrain architecture and power strategy control, as well as models and methods for sizing the primary powertrain components.

Block diagram of the vehicle system architecture. Image Credit: Fabri, G et al., Sustainability

Observations

Because of the FESS losses, the useful energy recovered was only about 8 kWh. The FC stack power of 50 kW was generated by employing five modules of 10 kW each, but the bench FESS comprised four units of 50 kW power according to the motor power. During the flight, the mission reached a top speed of 64 km/h, with negative and positive acceleration peaks of 1.4 m/s2 and 1.21 m/s2, respectively. The logged positive and negative peaks of the slope were +6.8 and -4.8, respectively, due to the partly distinct outbound and return courses.

Simulation analysis based on the created energetic model verified the validity of the suggested vehicle architecture. Additionally, the input data, i.e., vehicle speed and path grade, were empirically logged on a city bus that operated in real traffic conditions over an urban bus line.

The results showed that the FESS bench had strong brake energy recovery capabilities and that the FC's control was capable of responding to output energy changes that occur during driving. Although the auxiliary loads had a significant impact on energy consumption, their energy absorption when braking or driving downhill helped to keep the FESS state of charge (SOC) within its limits.

Despite the fact that the adopted RE-free motors were less efficient than RE-based motors, they appeared to be adequate from an energetic standpoint for the target vehicle application. The improvement of the fuel cell modeling and powertrain scaling were the next steps in the model's development.

Round trip line 143 of the Rieti local transportation network. Image Credit: Fabri, G et al., Sustainability

Conclusions

In conclusion, this study added to the enhancement of system modeling by incorporating a precise representation of the efficiency of electric motors and converters. The adoption of an energy storage flywheel system instead of chemical batteries and the use of RE-free electric motors in both the FESS bench and the electric drive-train are the two primary elements of the proposed powertrain. A specialized efficient model of the RE-free motor drive was chosen, and a suitable control strategy for the flywheel bench and the fuel cell stack was established to evaluate the effectiveness of the proposed design from an energy standpoint.

Data from a vehicle traveling in a metropolitan path covered by the transportation system of the public was recorded as a reference in order to validate the suggested more sustainable vehicle architecture. The proposed vehicle architecture was simulated using actual vehicle trip data to evaluate the energy flow between the powertrain's separate systems, indicating the effectiveness of the accepted architecture.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Fabri, G., Ometto, A., Villani, M., et al. A Battery-Free Sustainable Powertrain Solution for Hydrogen Fuel Cell City Transit Bus Application. Sustainability 14(9) 5401 (2022). https://www.mdpi.com/2071-1050/14/9/5401