A team of scientists from Romania has investigated the effect of acidic environments on the performance of power cables. Stresses which power cables face in the field have been analyzed by the authors using laboratory-based simulations of operating conditions. The results of their findings have appeared in the journal Energies.

Study: Study of the Accelerated Degradation of the Insulation of Power Cables under the Action of the Acid Environment. Image Credit: demarcomedia/Shutterstock.com

Background to the Research

Power cables are essential elements of modern infrastructure. Designing reliable cables which have a long life and minimal need for maintenance is vital for the consistent supply of electricity to urban and rural areas. However, several factors can affect the performance and lifespan of cables and change the dielectric material’s characteristics over time.

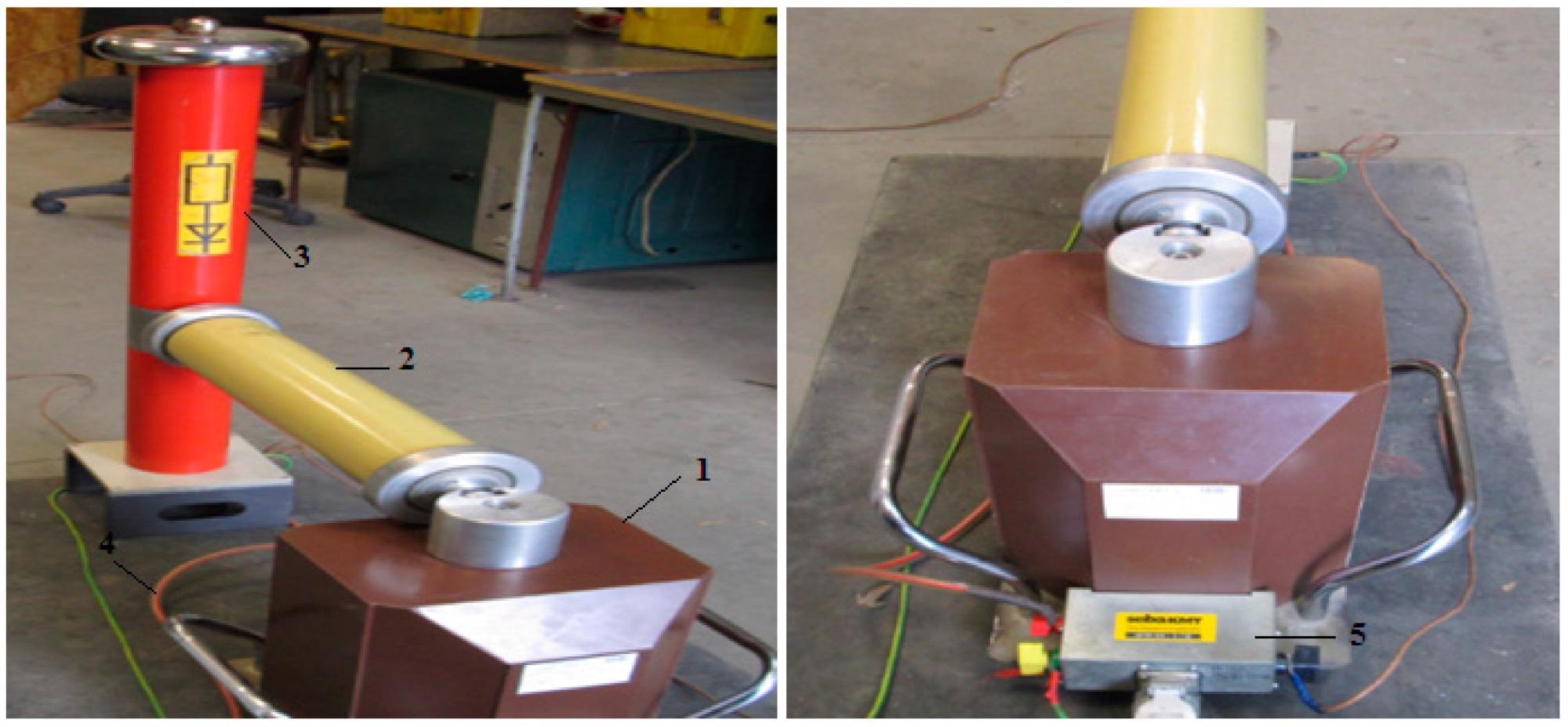

High-voltage test installation type HPG 70 D: (1) IT transformer; (2) Capacitor coupling and multiplication; (3) Multiplier rectifier diodes; (4) Connection cables; (5) Connection box. Image Credit: Preduș, M.F et al., Energies

In environments that have high pollution and levels of acidity, the chemicals present can penetrate the insulating coverings of cables. This changes the properties of the insulation and leads to decreased operating times. This leads to the cable being decommissioned and replaced, adding to maintenance burdens and interrupted power supplies.

Different voltages are supplied during cable operation. Current studies have been conducted on the behavior of electrical insulating materials at low voltages, with different methods employed to investigate degradation and highlight its effect in these conditions.

In lower-intensity electrical fields, the breakthrough phenomenon is preceded by electrical discharges, and the occurrence of discharges tends to occur in small portions of the insulation. Monitoring these partial discharges is essential to assess the state of insulating materials.

The Research

The research has investigated the degradation mechanisms of insulating materials in operational conditions using lab-based experiments. Samples of PVC and XLPE were selected by the authors for the experiments. Measurements at predetermined intervals were conducted.

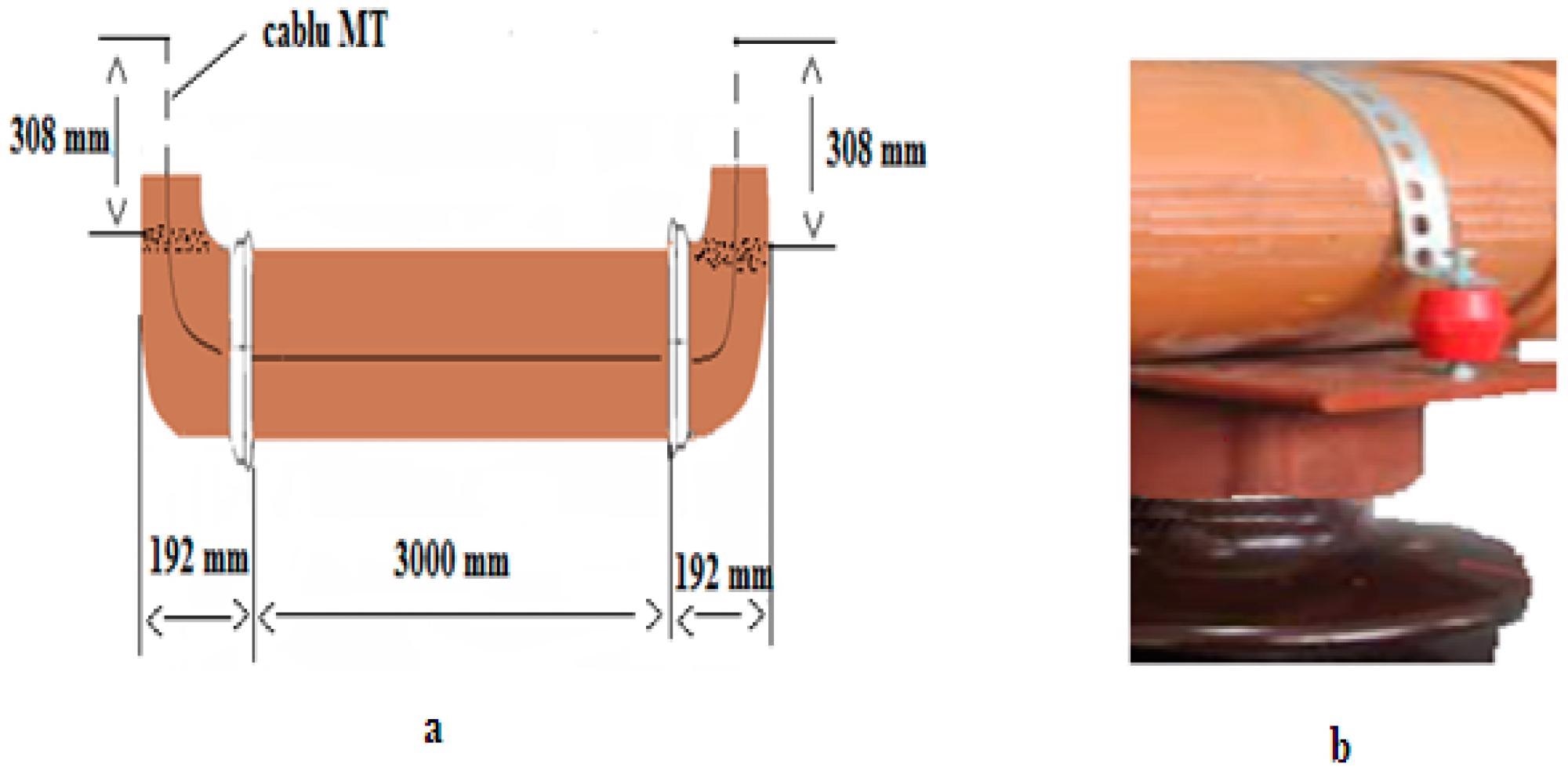

Samples were placed in a rigid PVC pipe containing electrolytes. The composition of the electrolyte was formulated to simulate environmental conditions that cables experience during their operational lifespan. The electrolyte was composed of sulphuric acid and nitric acid and diluted with water to mimic acid rain. A 4 m length of monopolar cable was inserted into the experimental equipment with both ends protruding from the equipment to avoid contouring phenomena.

A two-stage test was performed on the cable samples. Firstly, samples were tested at voltages above the recommended voltage. Insulation resistance, conduction currents, and electrolyte temperature were monitored at intervals of 24 hours. Cables were evaluated under direct current.

The second stage involved testing samples without the presence of a supply voltage. The samples were only subjected to the acidic environment of the electrolyte present in the equipment. At regular time intervals, different voltage values were used to refuel the electrolyte, and the samples were monitored until degradation occurred.

(a) Assembly of the multilayer PVC pipe, fireproof type SN4-125×3.2, PVC elbow type D125 87°; (b) Method used for fixing the tube on the IT insulating support. Image Credit: Preduș, M.F et al., Energies

Results of the Study

The paper highlighted three key findings from the experimental analysis of electrical cables. Under normal operating conditions at nominal voltage values, the insulation is kept at a positive temperature, influenced by the circulating conduction current. In this case, electrolyte absorption is reduced.

When the supply voltage is higher in relation to nominal voltage, continuous insulation degradation occurs because of elevated heating, leading to a loss of insulating properties and a rapid decrease in insulation resistance. Finally, when there is no supply voltage, the degradation process increases, and the cable’s internal temperature decreases with electrolyte temperature. This is due to the elevated absorption of electrolytes, again causing insulation resistance to significantly decrease.

Validation of the results was conducted to confirm insulation degradation behavior in cables in environments such as mining areas, near industrial waste, and environments with high water pH. Insulation defects were characterized by breakdowns induced by aggressive acidic substances, with the insulation material becoming a gelatinous substance. This was especially pronounced near joint sleeves.

Visualization of the place of breakdown of the insulation: (a) after the removal of the outer shell; (b) after the removal of the semiconductor layer. Image Credit: Preduș, M.F et al., Energies

Recommendations of the Study

Based on the experimental findings, the authors have made a series of recommendations. Firstly, connection sleeves and cables for electrical insulation should be constructed of materials with superior chemical resistance. This will limit the effect of acidic environments on electrical cables.

Due to the results obtained for degradation without the presence of a voltage supply, it is recommended that unpowered electrical cables should be avoided wherever possible, especially for prolonged periods. Moreover, operating cables at higher voltages than the recommended values should be avoided as this accelerates the degradation process.

The study has provided important insights into the degradation behavior of electrical cable insulation in real operating conditions. This will help to identify the cause of defects and prevent premature penetration occurring, limiting the lifespan of cables.

Further Reading

Preduș, M.F et al. (2022) Study of the Accelerated Degradation of the Insulation of Power Cables under the Action of the Acid Environment Energies 15(10) 3550 [online] mdpi.com. Available at: https://www.mdpi.com/1996-1073/15/10/3550

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.