By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.May 17 2022

By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.May 17 2022 In an article recently published in the journal ACS Applied Energy Materials, researchers discussed the utility of non-textured and textured anti-reflective coatings for planar monolithic silicon-perovskite tandem solar cells.

Study: A Comparison of Different Textured and Non-Textured Anti-Reflective Coatings for Planar Monolithic Silicon-Perovskite Tandem Solar Cells. Image Credit: Wichien Tepsuttinun/Shutterstock.com

Background

Perovskite silicon tandems combine emerging perovskite thin-film materials with well-established silicon technology. Due to the fewer interlayers required, two-terminal monolithic devices have the advantages of simplified processing and lower parasitic absorption over four-terminal devices; however, they must be carefully constructed to assure current matching in both the sub-cells.

The planar top silicon sub-cell allows standard solution processing, allowing for the best efficiency perovskite films in single-junction devices and low-cost, scalable perovskite device manufacture. Anti-reflective coatings (ARCs) have been employed in the majority of the efficient devices on the flat silicon bottom cells to reduce reflection losses.

Due to their advantageous refractive indices, commercially available planar films like MgF2 and LiF have been utilized to increase tandem cell performance. Textured anti-reflective films, which have been proved to be effective in the silicon-perovskite tandem cells, are increasingly being considered as a possible method for providing this light trapping on flat surfaces. Random inverted pyramid textures applied to solar cells have been proven to outperform upright pyramids, in addition to lowering the number of process steps.

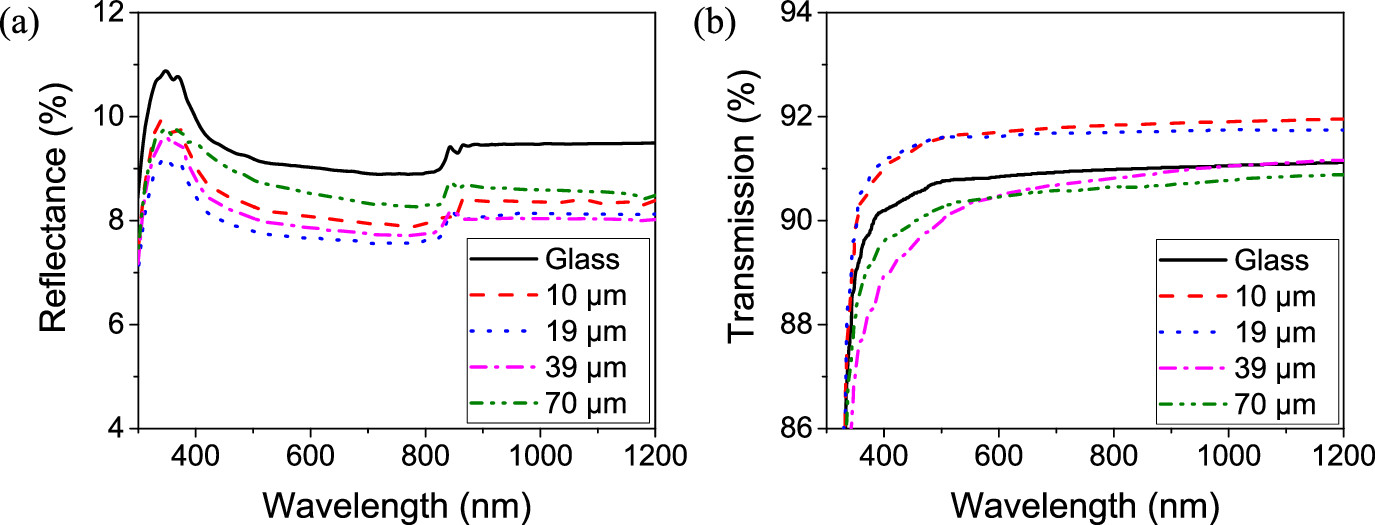

(a) Percentage reflectance and (b) percentage transmission spectra for planar PDMS layers of different thicknesses coated on soda-lime glass substrates. Image Credit: Michael Spence et al., ACS Applied Energy Materials

About the Study

In this study, the authors discussed the role of change in the texture geometry and film thickness of PDMS anti-reflective foils on the foil's reflectance. The best film was chosen, and its anti-reflective performance was compared to that of two standard planar ARCs, MgF2 and LiF, to reveal a significant decrease in reflectance for a non-textured silicon-perovskite tandem cell.

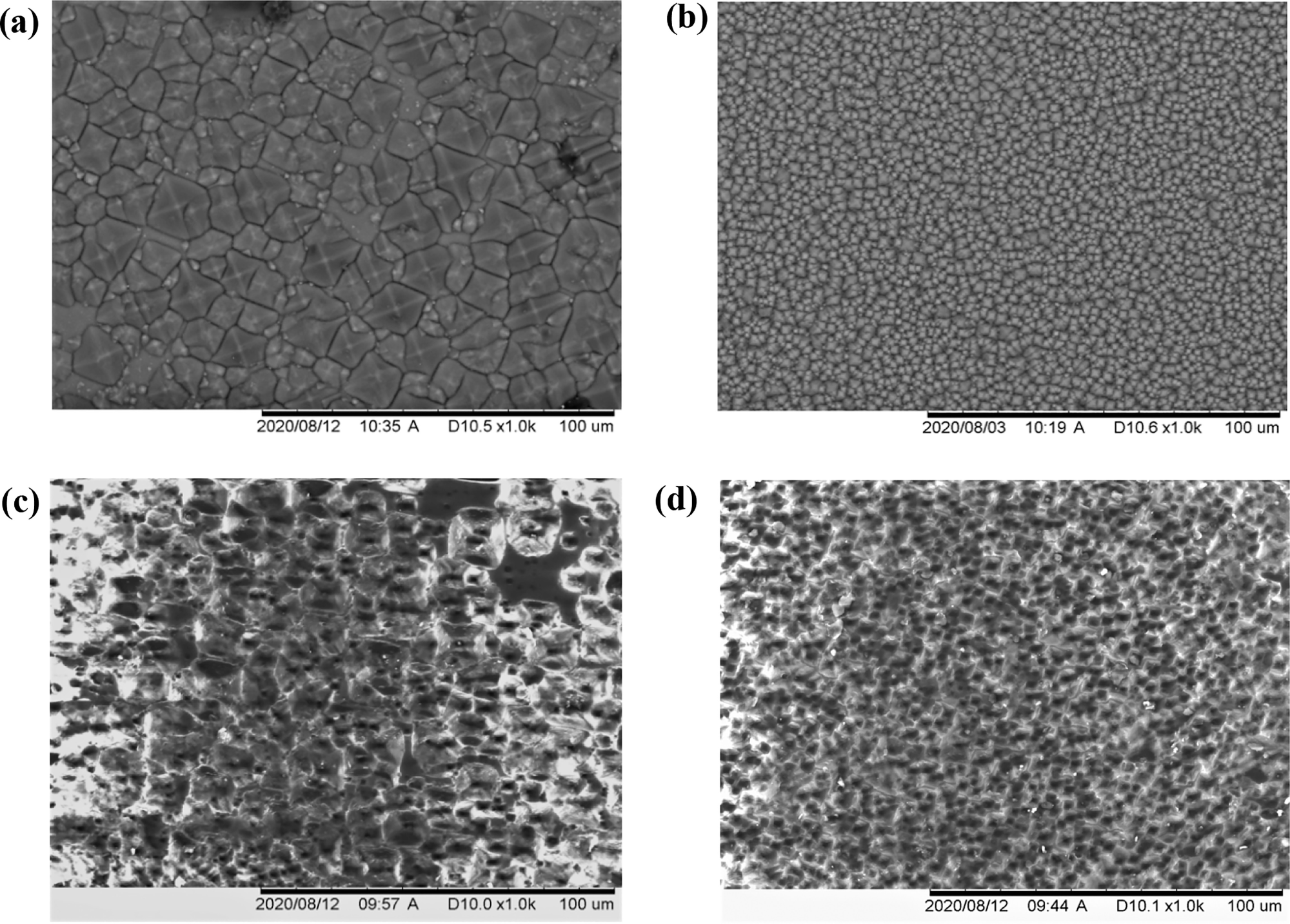

The researchers investigated the optical properties of non-textured and textured anti-reflective materials. The anti-reflective foils were made of polydimethylsiloxane (PDMS). Inverted pyramid textured and planar PDMS foils were made, and the effect of layer thickness on each type of the foil's optical performance was studied.

The team evaluated the impact of thickness and pyramid size of the foil on the antireflective qualities of the anti-reflective coating. Overall reflection was compared to common planar anti-reflective layers after the top-performing textured ARC layer was added to a non-textured silicon-perovskite tandem.

Scanning electron micrographs of (a) micron (T1) and (b) sub-micron (T2) scale silicon molds and the corresponding (c) micron and (d) sub-micron scale inverted pyramid textured PDMS layers produced by these molds. Image Credit: Michael Spence et al., ACS Applied Energy Materials

Observations

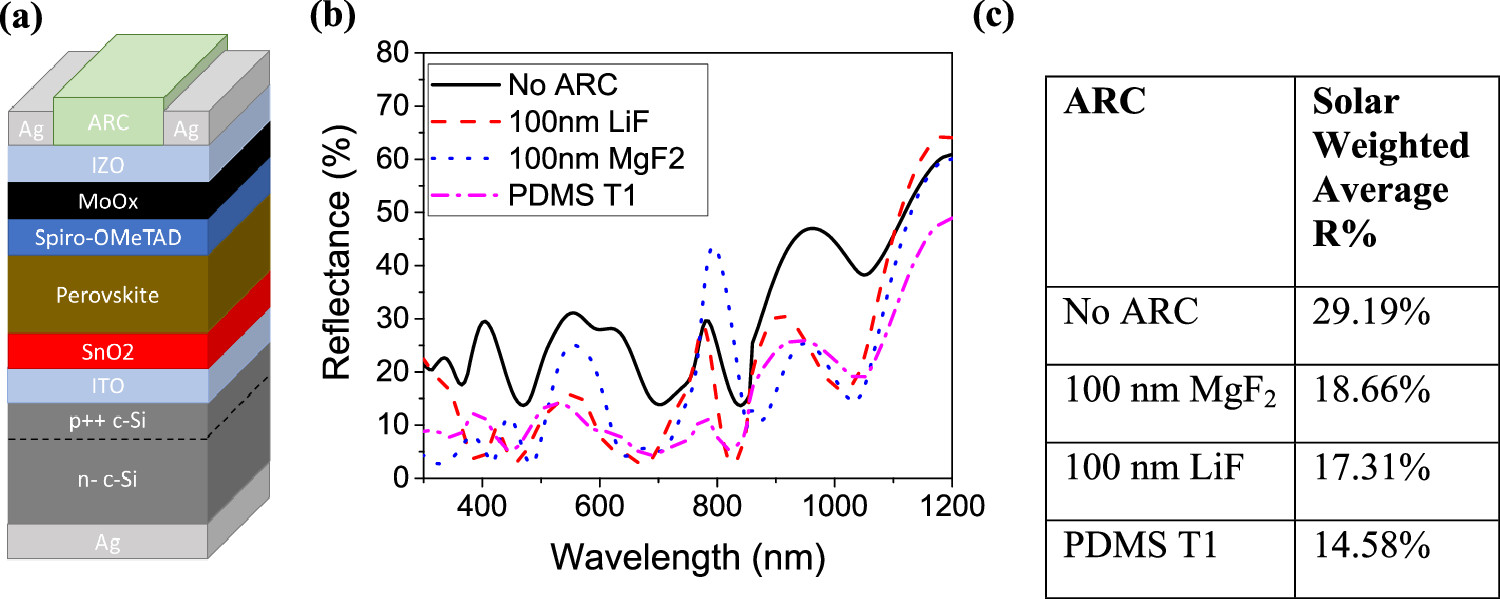

With a reflectance peak at 770 nm, the LiF showed a negligible loss in reflectance for wavelengths beyond 1100 nm and below 350 nm. With an average weighted reflectance of 29.19% across the 300-1200 nm range, the tandem structure exhibited a high reflectivity.

The tandem device with the textured PDMS anti-reflective layer had the lowest solar weighted average reflectance of 14.58%, while the LiF and MgF2 had higher weighted average reflectance of 17.31 and 18.66%, respectively, but were still inferior to the textured PDMS ARC. In each sub-cell of a silicon-perovskite tandem device, the use of a PDMS coating resulted in a 3-5% increase in integrated JSC.

Due to a tiny but considerable rise in external quantum efficiency (EQE) between 850 and 1000 nm, the silicon showed a bigger improvement of 0.58 mA cm-2 with the application of the textured PDMS ARC. Due to its higher JSC, the perovskite showed a smaller absolute rise of 0.50 mA cm-2, which resulted in a smaller percentage gain in an integrated JSC of 3%. After the application of textured PDMS ARC to the tandem, the total produced current density increased by 1.08 mA/cm2. After applying the textured anti-reflective foil, quantum efficiency measurements of the identical tandem indicated significant gains in integrated photocurrent.

When applied to a silicon-perovskite tandem, the textured film with the best thickness and texture height showed superior anti-reflective performance. For a silicon-perovskite tandem with a planar top surface, the best performing textured PDMS ARC resulted in a nearly 50% reduction in average reflectance.

For the measured tandem device, this resulted in a small but considerable increase in an integrated JSC of greater than 0.5 mA cm-2 in both perovskite and silicon sub-cells.

By the addition of the film to an optimized single-junction perovskite cell, a 6% relative increase was achieved in integrated JSC. The anti-reflective performance of the PDMS layer was influenced by both texture shape and total film thickness. A textured PDMS sheet, with some tweaking, outperformed standard planar anti-reflective coatings and helped decrease reflection losses in non-textured silicon-perovskite tandem cells.

(a) Schematic of the flat surface silicon-perovskite tandem used for evaluation of different anti-reflective coatings. (b) Reflectance spectra of the flat surface silicon-perovskite tandem with the optimized micron scale PDMS ARC (T1) compared with the commonly used planar ARC. (c) Tabulated mean reflectance over 300–1200 nm for the silicon-perovskite tandem with each ARC. Image Credit: Michael Spence et al., ACS Applied Energy Materials

Conclusions

In conclusion, this study elucidated a straightforward approach for fabricating an inverted pyramid textured film of PDMS that was compatible with the silicon-perovskite tandem solar cells. Different thicknesses of the planar film were examined, and it was discovered that a 19 μm film formed by spin coating at 3000 rpm produced the best reflectance losses.

A film mostly formed of sub-micron pyramids had reduced reflection losses than a wider texture geometry having an average height of pyramid as 8 μm. The thinnest foil that could be delaminated had the best anti-reflective qualities in terms of overall film thickness.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Michael Spence, Richard Hammond, Adam Pockett, Zhengfei Wei, Andrew Johnson, Trystan Watson, and Matthew J. Carnie. A Comparison of Different Textured and Non-Textured Anti-Reflective Coatings for Planar Monolithic Silicon-Perovskite Tandem Solar Cells. ACS Applied Energy Materials 2022 5 (5), 5974-5982. https://pubs.acs.org/doi/10.1021/acsaem.2c00361 DOI: 10.1021/acsaem.2c00361