Writing in the journal Polymers, a team of researchers from the United Arab Emirates University has reported the development of a recycled carbon fiber/PLA composite to valorize waste streams and meet growing commercial demands for both materials.

Study: Carbon Fiber/PLA Recycled Composite. Image Credit: Ihor Matsiievskyi/Shutterstock.com

Sustainable Polymers

In recent decades, there has been a growing awareness of the environmental damage caused by human activity. Polymeric materials have shown widespread application in multiple industries due to their favorable mechanical and physiochemical properties, but their manufacture comes with a huge environmental cost due to their accumulation, non-biodegradability, and toxic by-products.

Several strategies have been proposed to address these issues, including manufacturing green plastics by incorporating organic biopolymers, recycling plastic products, and reusing waste streams to produce value-added products such as biofuels, construction materials, and industrial chemicals.

Polylactic acid (PLA) is a commonly used biopolymer, possessing both biodegradability and bioactive properties. This polymer has found widespread application in the automotive, 3D printing, and packaging industries among numerous commercial sectors. PLA is, however, limited for several commercial applications by its lack of thermal and mechanical stability.

Chemical Structure of Polylactide Acid. Image Credit: Al Zahmi, S et al., Polymers

Several composites composed of PLA and filler materials such as carbon fiber, carbon nanotubes, and various organic and inorganic nanomaterials have been developed in recent years to improve the mechanical and thermal properties of this biopolymer. Composites produced from natural fibers and biopolymers such as PLA provide benefits such as biodegradability for a wide range of commercial uses.

Recycling these composites is problematic, however, due to their complex compositions. Mechanical recycling strategies have proven to be the most effective method as they are resource-efficient. However, these processes can be hindered by exposure of materials to harmful substances during recycling.

PLA recycling is a key focus within the green polymer industry, as the eco-friendliness of this material can be retained, and polymers can be reused to manufacture several commercial products. Moreover, PLA is heavier than other commercial polymers such as HDPE and LDPE, meaning that it can be easily separated by density.

Carbon Fiber Reinforced Polymers

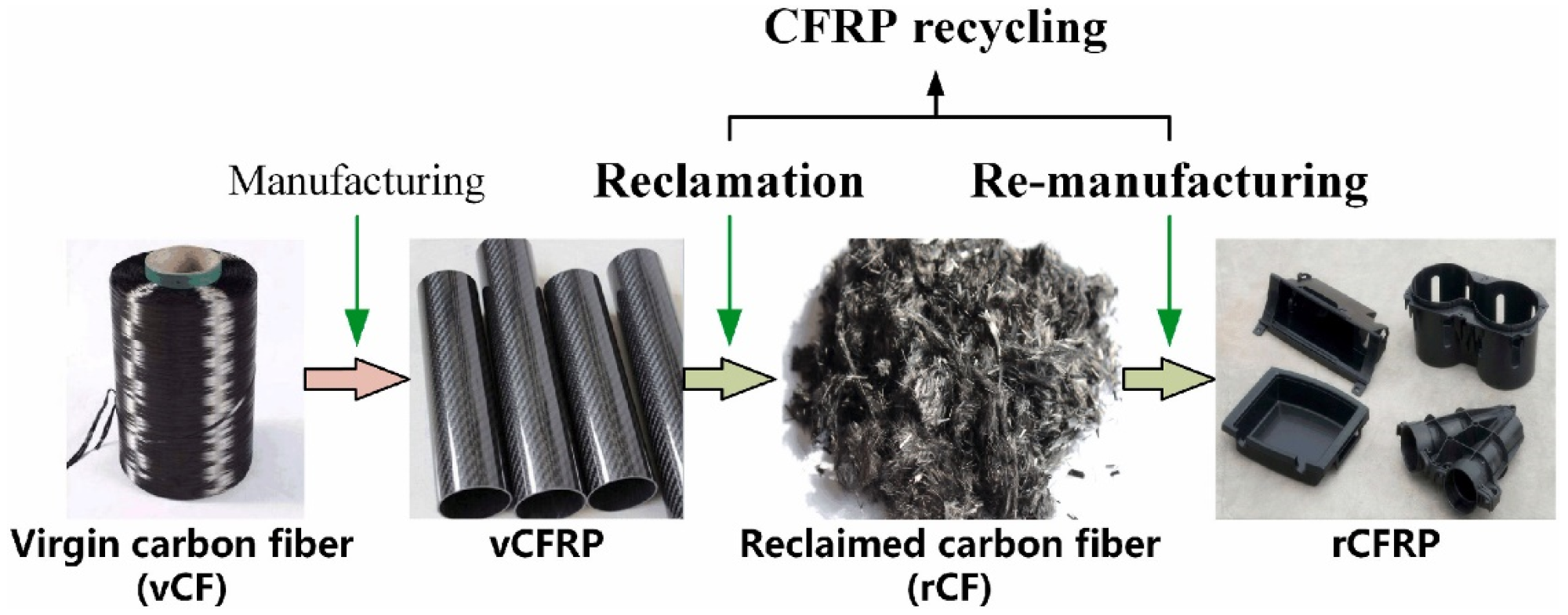

Carbon fiber reinforced polymers have drawn the attention of recent research due to their favorable properties and commercial applications. Since the discovery of carbon fiber in the 1960s, production of this material has increased exponentially to meet the demands of industries such as aviation, transportation, construction, and biomedicine.

Carbon fiber reinforced polymers have also received research focus due to the growing amount of plastic waste caused by increasing plastic consumption. The demand for carbon fiber reinforced polymers is predicted to increase over the coming decades.

Materials can be easily recycled using 3D printing methods. Scrap prepreg can be incorporated into recycled materials to provide enhanced physiochemical, thermal, and mechanical properties. Several studies have reported the manufacture of viable commercial products from recycled carbon fiber composite polymers.

There are, however, challenges associated with recycling and reusing these materials, such as difficulty with heating, shaping, processing, and re-crosslinking processed thermoset carbon fiber reinforced polymers. Due to the substantial benefits of these materials in terms of sustainability and eco-friendliness, research has focused on improving the recyclability of carbon fiber reinforced polymers.

Recycling Process from Virgin Carbon Fiber to CFRP. Image Credit: Al Zahmi, S et al., Polymers

The Study

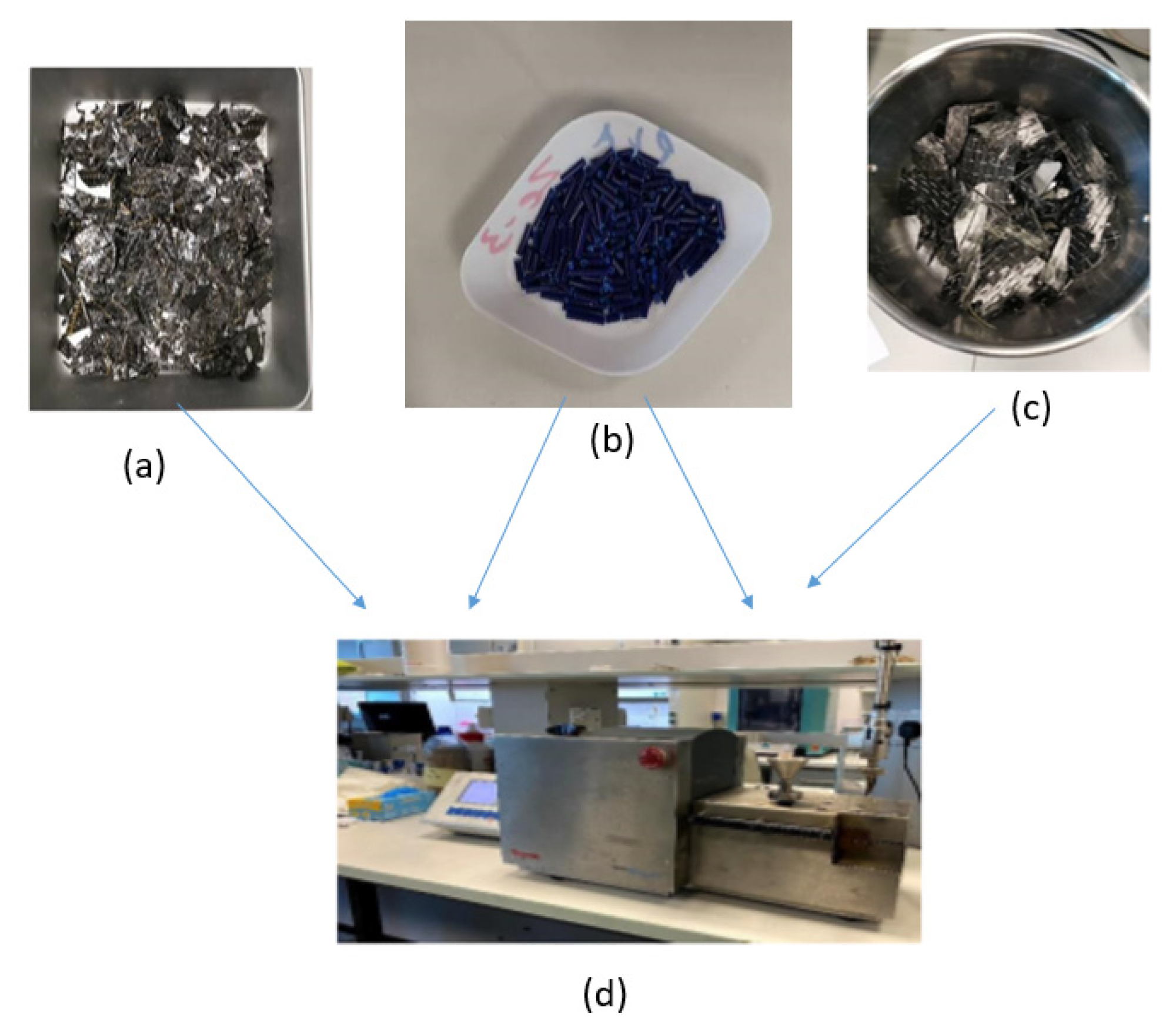

The paper has investigated two different waste materials, polylactic acid, and carbon fiber leftovers. The main objective is to produce and characterize composite materials to provide solutions to increasing industrial waste. Several tests have been performed to study how carbon waste reinforcements impact the properties of processed PLA/carbon fiber composites.

Composite PLA/carbon fiber material samples with different additive percentages were prepared using shredding, grinding, mixing, and melt-blending. A universal testing machine was used to characterize the effect of additives on the composite samples. FTIR, XRD, and TGA testing was employed by the authors to investigate various properties and structural characteristics of the samples.

Study Findings

The authors observed different impacts on composite performance depending on the percentage and type of filler used. For instance, a 20% carbon fiber composite possesses a higher modulus of elasticity than a 20% carbon fiber-prepreg sheet composite. Yield strength was also highest in the 20% carbon fiber composite sample.

Generally speaking, carbon fiber enhanced the PLA composite’s ultimate strength. Negative effects on ductility composite materials using carbon fiber reinforcements was observed, however. Overall, the use of recycled PLA and carbon fiber fillers offers benefits for the manufacture of commercial products in terms of cost, processing efficiency, and simple recycling methods for waste streams.

Samples of (a) CFRP, (b) PLA, (c) CF, (d) twin-screw extruder. Image Credit: Al Zahmi, S et al., Polymers

The study has demonstrated a novel approach to recycling both plastic and carbon fiber waste streams from numerous industries. The composite materials produced in the research can be considered for the manufacture of several commercial products, using different blend ratios to achieve the desired properties.

Whilst the economic benefits of this process have yet to be explored, the authors hope their research will provide a starting point for future research into carbon fiber reinforced polymer composites.

Further Reading

Al Zahmi, S et al. (2022) Carbon Fiber/PLA Recycled Composite Polymers 14(11) 2194 [online] mdpi.com. Available at: https://www.mdpi.com/2073-4360/14/11/2194

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.