A team of researchers recently published a paper in the journal Energies that demonstrated the feasibility of using gas hydrates in power plants.

Study: Prospects of Using Gas Hydrates in Power Plants. Image Credit: ETAJOE/Shutterstock.com

Background

The addition of water to fuels during combustion can help in stabilizing and homogenizing the fuel, minimizing anthropogenic gas emissions, and stabilizing the combustion process to improve explosion and fire safety. Water can be injected as vapor or droplets in the furnace and introduced as part of the fuel samples. Typically, water serves as a carrier or coupling medium for the main fuel component delivery.

Gas hydrates have attracted considerable attention as high-potential fuels with the increasing energy consumption across the world. These compounds of gas and water are formed at high pressures and low temperatures. Ninety percent of marine gas hydrates contain methane. In gas hydrates, methane molecules are trapped in the stable cage-like structure formed by hydrogen-bonded water molecules.

Coal-water slurries (CWS) represent another alternative approach that involves water-based resources in the power generation sector. CWS is a mixture of water with 35 to 65 wt% mass concentration and coal components. Special-purpose additives, such as oil sludge, used oils, and biomass, can be added with 5–20 wt% mass concentrations to the CWS to reduce or increase certain characteristics.

These fuels can be produced from an extensive range of resources, specifically from different quality coals such as low-rank brown coals or high-rank anthracite coals and their processing waste, such as coal slime.

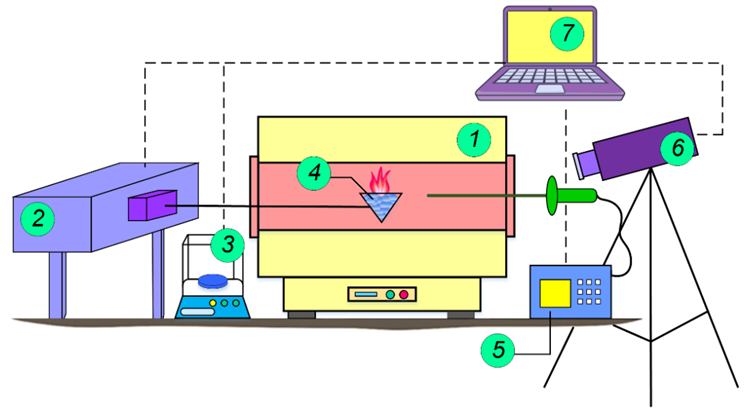

Scheme of the setup for studying the fuel ignition behavior on radiative heating: 1—muffle furnace; 2—positioning mechanism; 3—electronic balance; 4—metal holder with a fuel sample; 5—gas analyzer; 6—high-speed video camera; 7—laptop. Image Credit: Antonov, D et al., Energies

The Study

In this study, researchers compared the combustion and ignition behaviors of high-potential gas hydrates and slurry fuels using mathematical modeling and physical experiments to identify the conditions in which these fuels can burn effectively in power generation plants.

They analyzed the contribution of gas hydrates and slurries to the combustion process and determined their relative combustion efficiency indicator (An) values. Researchers also determined the total performance value of these fuels using multi-criteria decision-making (MCDM).

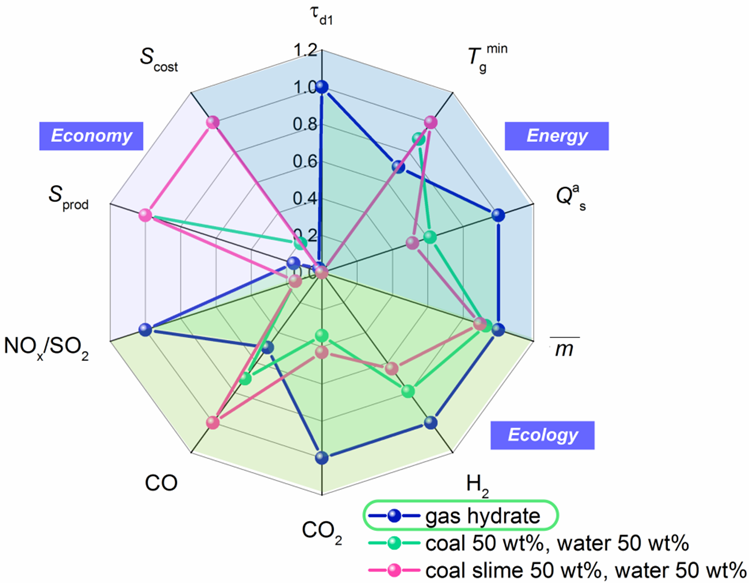

The relative performance indicators of gas hydrate and slurry fuels were determined by considering the energetic parameters such as burnout degree, calorific value, ignition delay times (τd1), minimum ignition temperature (Tgmin), economic parameters such as fuel cost, and environmental parameters such as anthropogenic gaseous emissions.

Specifically, sulfur dioxide (SO2), nitrogen oxide (NOx), carbon monoxide (CO), carbon dioxide (CO2), and hydrogen (H2) emissions were detected in the gas mixture generated from hydrate and slurry fuel combustion.

Combustion of Gas Hydrates

Methane–propane hydrate with 60% methane and 40% propane was used to investigate the combustion and ignition behaviors of gas hydrate theoretically and experimentally. The gas hydrate was used as a powder with a granule size of 0.25 mm.

The ignition behavior of the hydrate was investigated experimentally by radiative heating of the gas hydrate powder using a muffle furnace heated at high temperatures.

Samples of gas hydrate were ignited in a motionless high-temperature air medium generated in a hollow ceramic tube of the R 50/250/13 muffle furnace. The furnace air temperature varied between 700 and 1000 oC and was observed using an in-built type S thermocouple. The muffle furnace was heated to a specific temperature in every series of five experiments.

The gas hydrate at -70 oC/initial temperature was weighed using an AJH-620CE balance and placed in a reservoir/V-shaped fine metal mesh. The gas hydrate reservoir was then introduced into the heated furnace hollow tube using a positioning mechanism.

A high-speed video camera was used to record the processes occurring during the induction period, and the Tema Automotive software was utilized to analyze the obtained video recordings.

A Test 1 gas analyzer was introduced in the muffle furnace/central combustion zone to measure the concentration of main gases emitted during the combustion and a specialized test software was used to monitor the obtained gas concentrations.

The experimental findings were used to develop a mathematical and physical model simulating the gas hydrate ignition by radiative heating to determine the Tgmin and τd1.

The heat transfer solution domain in the numerical simulation under the radiative heating conditions was described using transient partial differential equations. The equations were solved using the finite difference method.

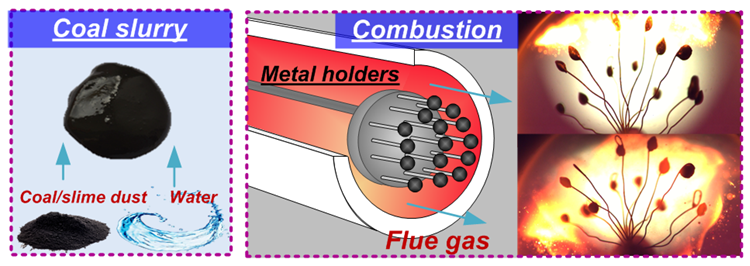

Combustion of coal–water slurry droplets. Image Credit: Antonov, D et al., Energies

Combustion of Slurry Fuels

The combustion and ignition behaviors of slurry fuels were analyzed based on the experimental data. Coking bituminous coal and its processing waste, coal slime, were used to synthesize two slurries with 50% coal/coal slime and 50% tap water mass fractions.

The concentration of the gases emitted during combustion, gas-phase ignition delay (τd1), burnout degree, heterogeneous ignition delay (τd2), and Tgmin were determined to characterize the slurry droplet combustion and ignition. The calorific value (Qas) of the slurry fuels was also measured.

The experimental setup used during the gas hydrate ignition and combustion was also employed for this study, excluding the technique used to introduce the fuel in the combustion chamber.

The variation range of furnace temperature was 700-1000 oC for ignition and combustion of fuel slurries. The combustion stage was followed by active vaporization, where the concentration of the emitted gases after fuel slurry combustion was measured.

The efficiency indicators were calculated using the average values obtained in a series of experiments. The outliers were removed and the variation coefficients were determined for all measured coefficients, and the confidence interval was calculated with a 0.95 confidence probability.

Observations

The ignition and combustion behaviors of coal/coal slime-water slurries and methane-propane hydrate were investigated. The Tgmin of the methane-propane hydrate was 570 oC. The τd1 of the gas hydrate reduced from 0.043 s to 0.005 s with the increasing temperature of the radiative heating source.

The concentration of the gaseous products generated from the hydrate combustion increased by 2.5 times with a rise in temperature from 700 to 1000 oC. However, the zero SO2 emission was the major environmental advantage of gas hydrates over the traditional fuels.

The Tgmin of the coal-water and coal slime-water slurries were 450 oC and 400 oC, respectively, while the τd1 of the was 20% shorter in the coal-water slurry compared to the coal slime-water slurry. The burnout degree of the coal-water slurry was 2–6% higher than the coal slime-water slurry due to higher ash content in coal slime.

Relative performance values for three fuels (Rd = 2 mm, Tg = 900 °C). Image Credit: Antonov, D et al., Energies

The NOx, CO, and CO2 emissions after coal-water combustion were 9–17%, 36–72%, and 26–33% higher compared to the emissions of these gases after coal slime-water combustion. However, the emission of SO2 was higher after coal slime-water combustion due to the presence of sulfur as the primary content in the fuel.

Based on ten separate indicators, including fuel cost and production cost, NOx, SO2, CO, CO2, and H2 emissions, and τd1, Tgmin, Qas, and burnout degree, gas hydrate demonstrated the highest total performance value compared to CWS. Moreover, the An value of gas hydrates at temperatures between 700 and 1000 oC was 10–31% higher than the slurry fuels.

Conclusion

Taken together, the findings of this study demonstrated the feasibility of using gas hydrates in power plants and could be used to predict conditions for effective gas hydrate combustion and the shortest possible ignition delay. The findings can also be used to rationalize alternative ways to involve water resources, such as composite fuel droplets and gas hydrates, in the power generation industry.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Antonov, D., Gaidukova, O., Nyashina, G. et al. Prospects of Using Gas Hydrates in Power Plants. Energies 2022. https://www.mdpi.com/1996-1073/15/12/4188