.jpg) By Susha Cheriyedath, M.Sc.Reviewed by Skyla BailyJun 24 2022

By Susha Cheriyedath, M.Sc.Reviewed by Skyla BailyJun 24 2022In a paper recently published in the open-access journal Materials, researchers studied the possibility of utilizing the pyrolysis of wood pellets to generate high-energy fuels. The study also established enhanced energy parameters of previously pelletized biomass pyrolysis, while concluding that there was no increase in the danger of dust explosion from the processing of solid biofuels.

Study: The Use of Wood Pellets in the Production of High Quality Biocarbon Materials. Image Credit: tchara/Shutterstock.com

Background

The need for alternate sources of energy for environmental sustainability and development demands the use of renewable energy such as biomass. A solid-state biomass fuel, wood pellets are manufactured by compaction of ground wood. Pellets, when compared to wood chips, have greater energy density per unit volume and mass. Their compact size facilitates ease of transportation and storage.

The use of pyrolysis allows the acquisition of low-carbon energy from biomass using common substrates like plants and waste biomass. Pyrolysis can be advantageous in increasing the calorific value as well as reducing the bulk density of the materials used.

Processing biomass into small-sized fractions is associated with hazards of dust explosion from the use of milling or crushing equipment. Fatal consequences can result when auto-ignition occurs in the presence of oxygen, combustible dust, dust cloud confinement, dispersion of dust particulates, and ignition. Prevention and control of dust explosions can be achieved by understanding the impact of the interactions between lignocellulosic biomass components. The present research aimed to evaluate the use of wood pellets for fuel production with an increase in the energy value using pyrolysis.

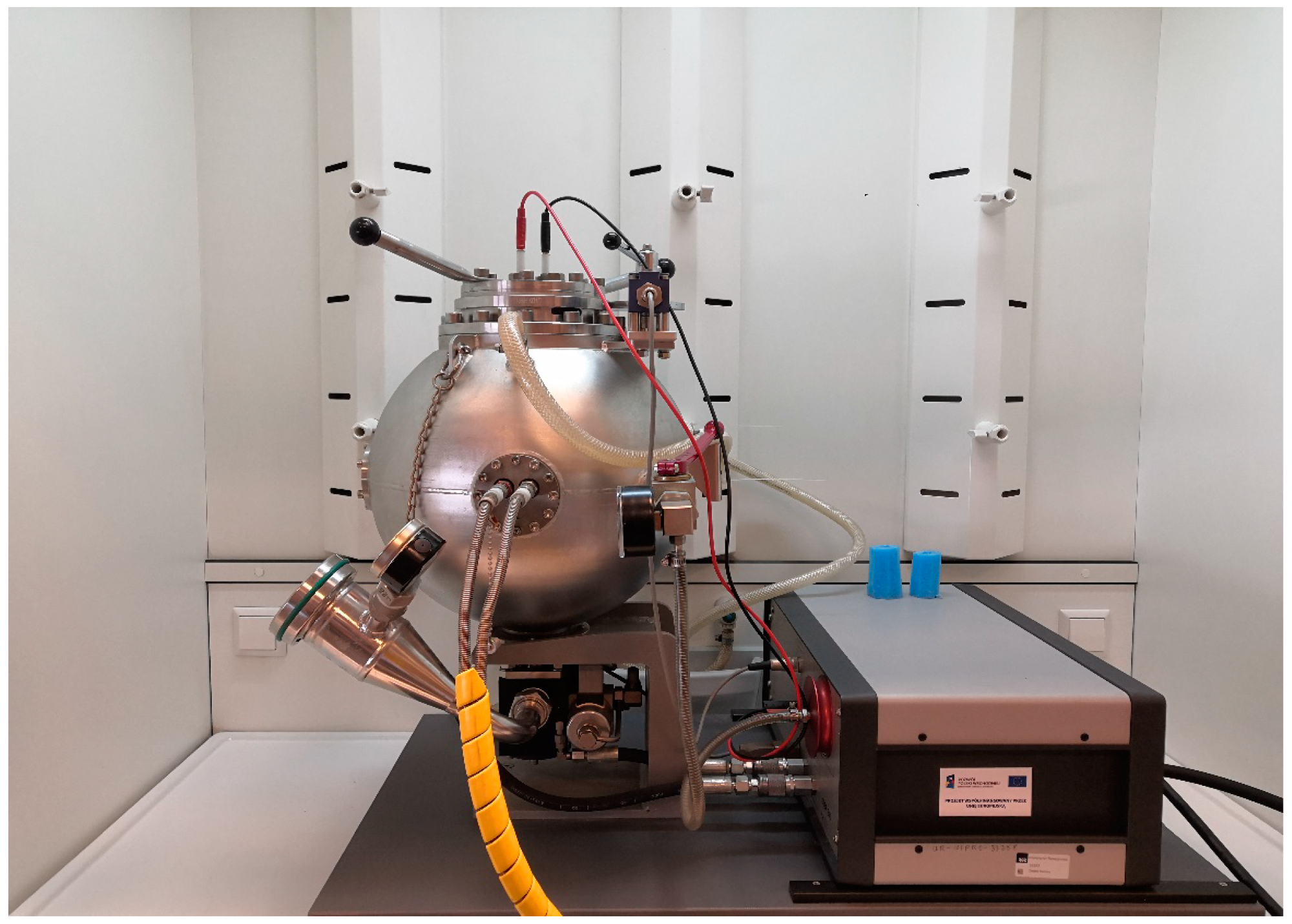

Pyrolysis retort furnace. Image Credit: Saletnik, B et al., Materials

About the Study

In this study, the team used various pellets from the Polish market made up of oak sawdust, coniferous sawdust, and mixed pellets consisting of coniferous and deciduous sawdust. A retort furnace FCF 2R was used to conduct pyrolysis on the test pellets. The samples were then analyzed to determine their physicochemical parameters as well as dust explosiveness.

Dust explosiveness was analyzed with the KSEP20 device featuring a test chamber with a 20 dm3 volume, which calculated the maximum explosion pressure of the combustible mixture present as combustible material with air. The volatile substances and ash contents were analyzed using a TGA 701 device based on a thermogravimetric method.

A Tumbler 1000 apparatus tested the mechanical durability of the samples while the content of heavy metals was measured on an ICP-OES spectrometer. The relationships between the impact of the experimental factors reproduced by the relevant parameters were studied using analysis of variance (ANOVA). The data for each pellet type were analyzed separately.

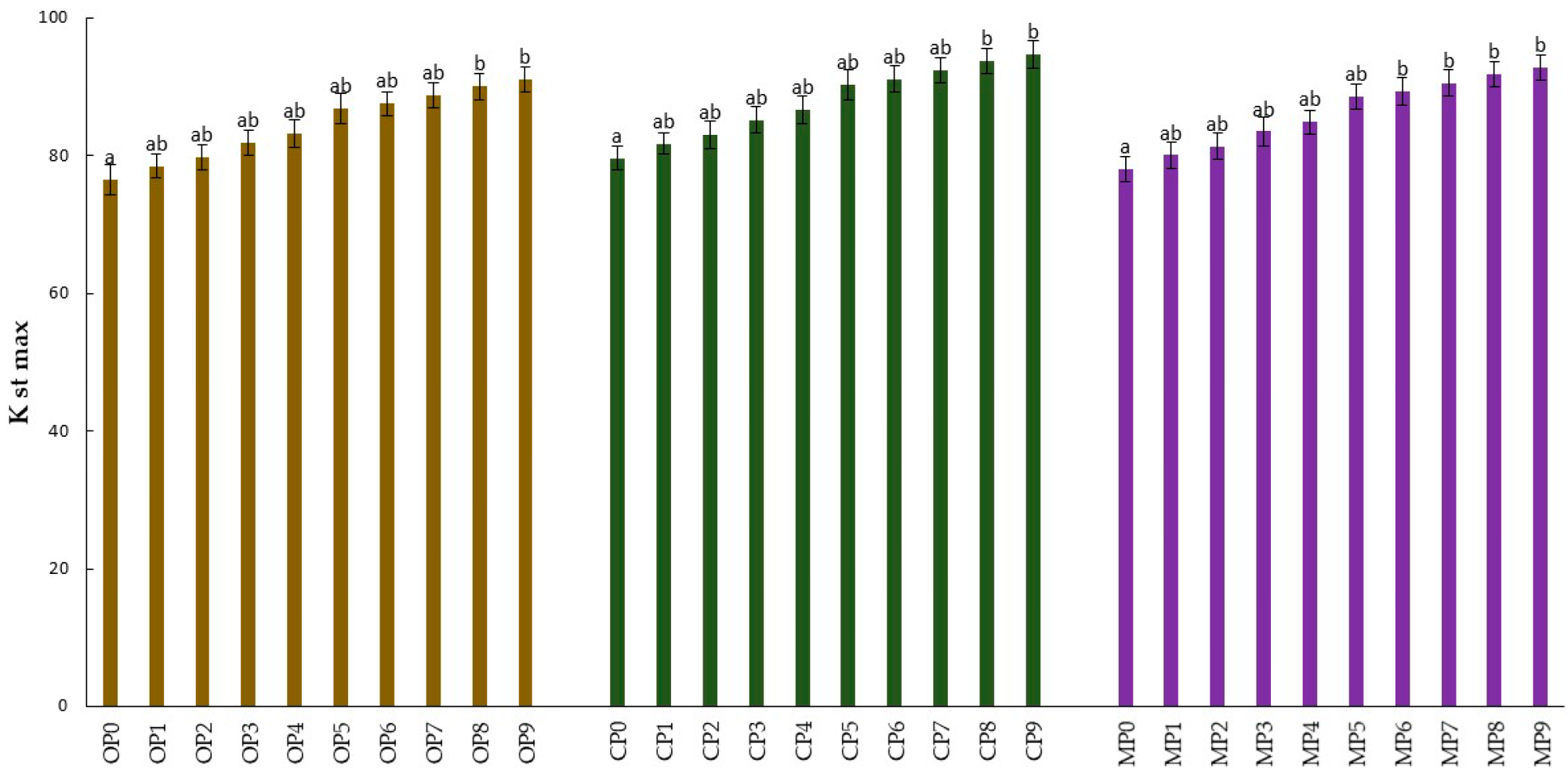

Explosivity Analyzer KSEP 310. Image Credit: Saletnik, B et al., Materials

Observations

The pellet samples showed no nitrogen content, which remained unchanged even after pyrolysis. Pyrolysis carried out at a temperature of 500 oC and a maintenance time of 15 minutes indicated the highest carbon content with oak pellets containing 81.41%, coniferous pellets containing 85.21%, and mixed pellets containing 83.32% carbon. The hydrogen content decreased for all tested materials during pyrolysis, while the ash content for the analyzed pyrolysates was highest for the longest time and maximum temperature.

On the other hand, the volatile substance content differed by more than 40% between the untreated pellet control sample and the pyrolysates. No elevated heavy metal content was detected in the tested pellets. The calorific value saw a substantial increase in the materials subjected to pyrolysis. Although the durability of the processed biocarbons (44.34-56.14%) decreased below the unprocessed sample value (average 98.84%), thermal modification of all test pellets indicated an average increase of 56% in the calorific value relative to the unprocessed sample at 500 °C and a time of 15 minutes.

Biocarbons obtained from the pyrolysis of wood pellets had a higher maximum dust explosion pressure by up to 47% in comparison to the control samples due to the increased fragility of biocarbons and higher volatile and carbon content. However, the rate of increase of maximum pressure was not significant to implement a change in dust classification. The mean explosivity index for the wood pellets was 78.07 bar s-1 and it averaged 87.04 bar s-1 for the biocarbons.

Dust explosivity index of oak, coniferous, mixed pellets and produced biocarbons. Statistically significant differences between values are marked by different letters (p ≤ 0.05). Image Credit: Saletnik, B et al., Materials

Conclusions

Overall, the findings show that the pyrolysis of the tested biochars can considerably increase the calorific value without decreasing the processing safety. A positive correlation was observed between total ash and carbon content, temperature, and the duration of pyrolysis. Thermal valorization showed a visible decrease in the volatile content. The decrease in the durability of the pellets did not affect the quality of the biofuels obtained.

The study pointed out that pyrolysis can be effective in producing biocarbons characteristic of a high calorific value along with safe production and usage. According to the authors, the pyrolysis of wood pellets to produce high-energy biocarbons can be a beneficial solution attractive enough in energy utility as a low-carbon source, with further research needed in this direction.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Saletnik, B.; Saletnik, A.; Zaguła, G.; Bajcar, M.; Puchalski, C. The Use of Wood Pellets in the Production of High Quality Biocarbon Materials. Materials 2022, 15, 4404. https://www.mdpi.com/1996-1944/15/13/4404