In a paper recently published in the journal Materials, researchers studied the influence of the morphological properties of manufactured sand (MS) and their correlation with particle shape and the properties of concrete. Five types of manufactured sands were tested for their mechanical properties, performance, and concrete durability. The results were used to evaluate the relationship between the shape parameters of the MS and the concrete properties.

Study: Particle Characterization of Manufactured Sand and Its Influence on Concrete Properties. Image Credit: Mariyana M/Shutterstock.com

Background

Concrete consists of coarse to fine aggregates that constitute at least three-quarters of its volume. Its vast applications have led to unsustainable exploitation of non-renewable natural sands, which raises the issue of sand scarcity with significant economic, sociopolitical, and economic consequences. This situation, coupled with the increasing development of infrastructure, has led to the search for alternative sand resources.

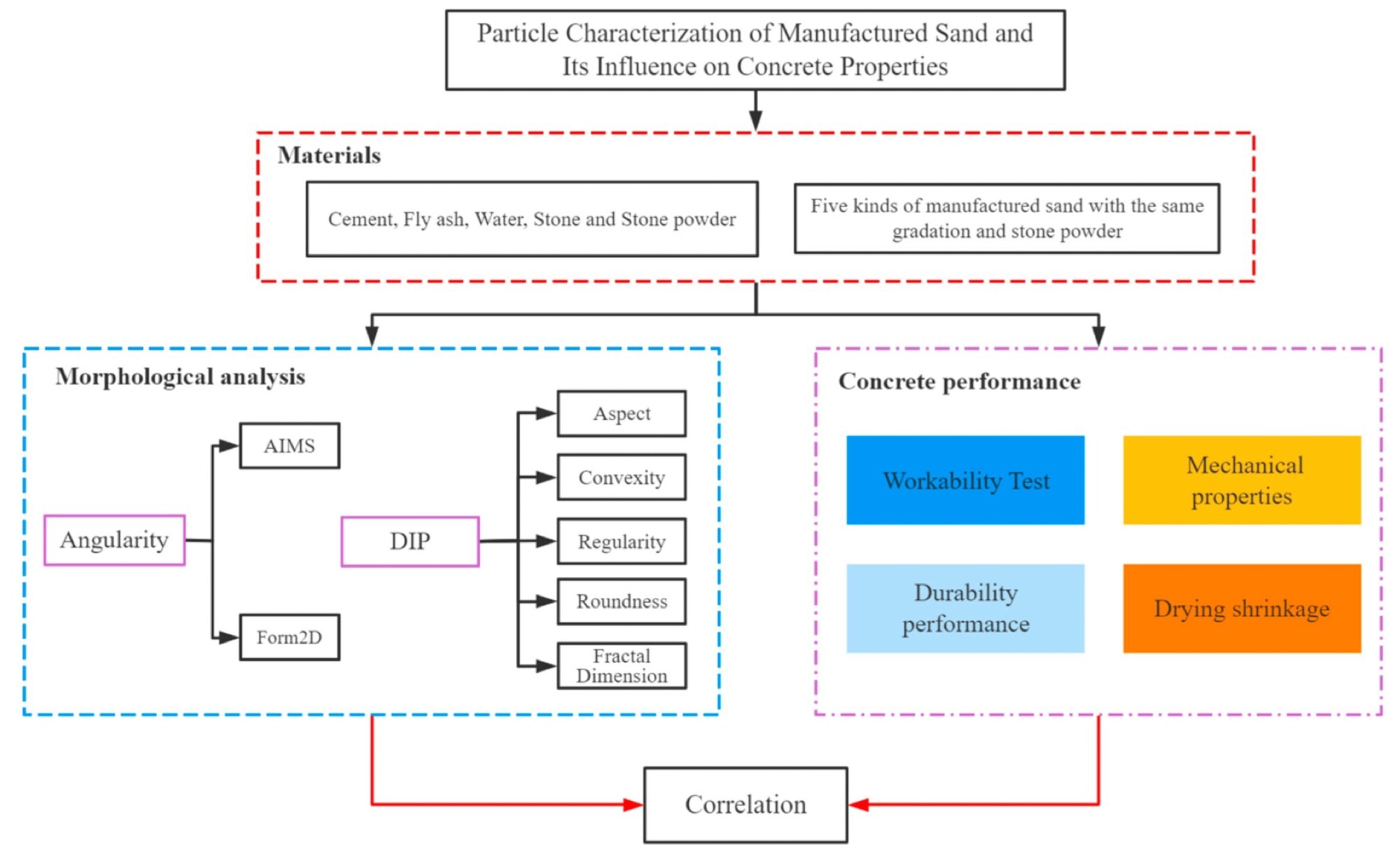

Technical route of this research. Image Credit: Wu, J et al., Materials

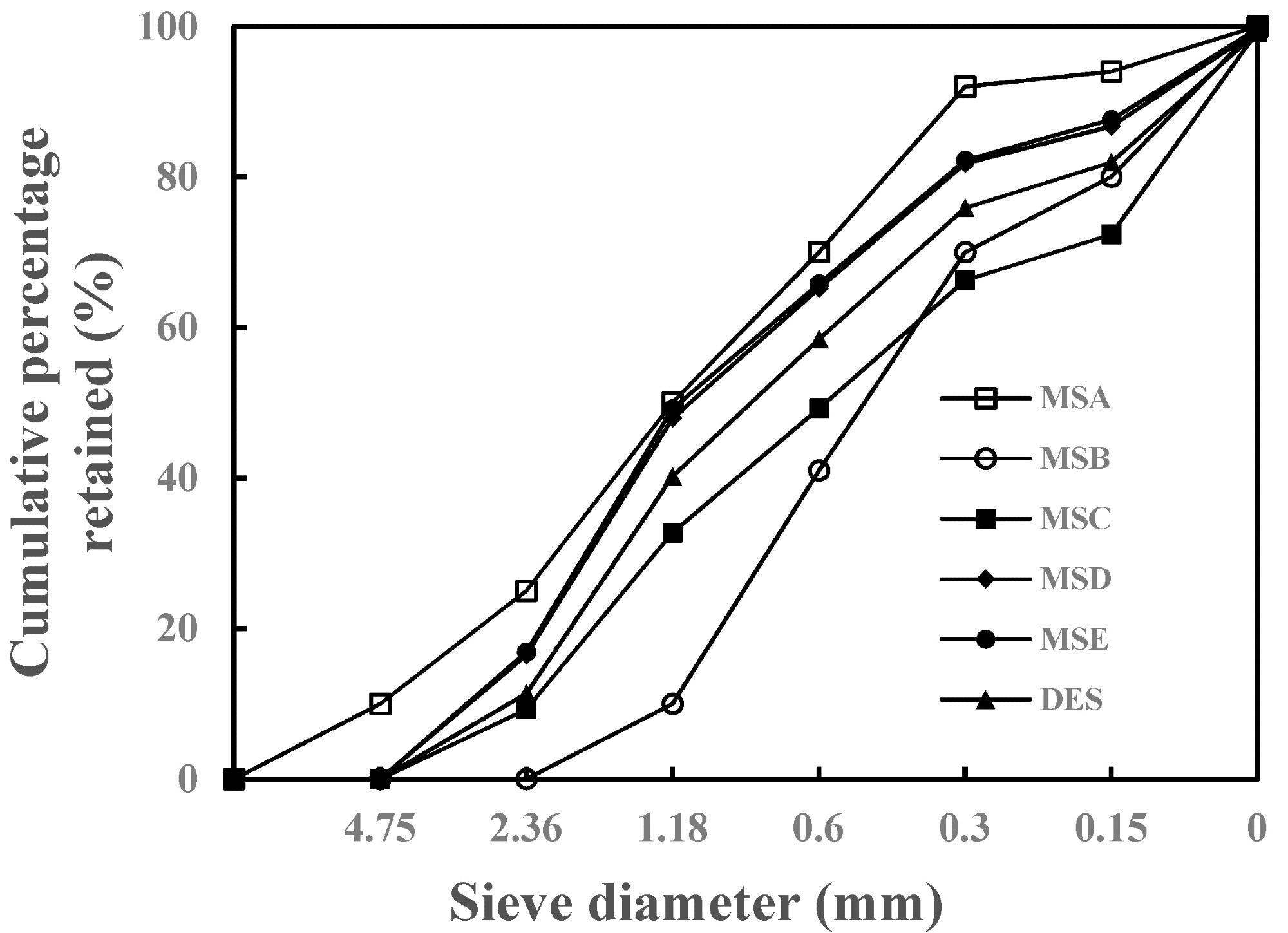

MS has been widely studied as the primary alternative to natural sand, despite having a rough surface, irregular shape, poor gradation, and the fact it contains high flaky particle content and stone powder. Current research has focused on the optimization of concrete performance based on methylene blue value (MBV), gradation, and stone powder content.

Materials and Methods

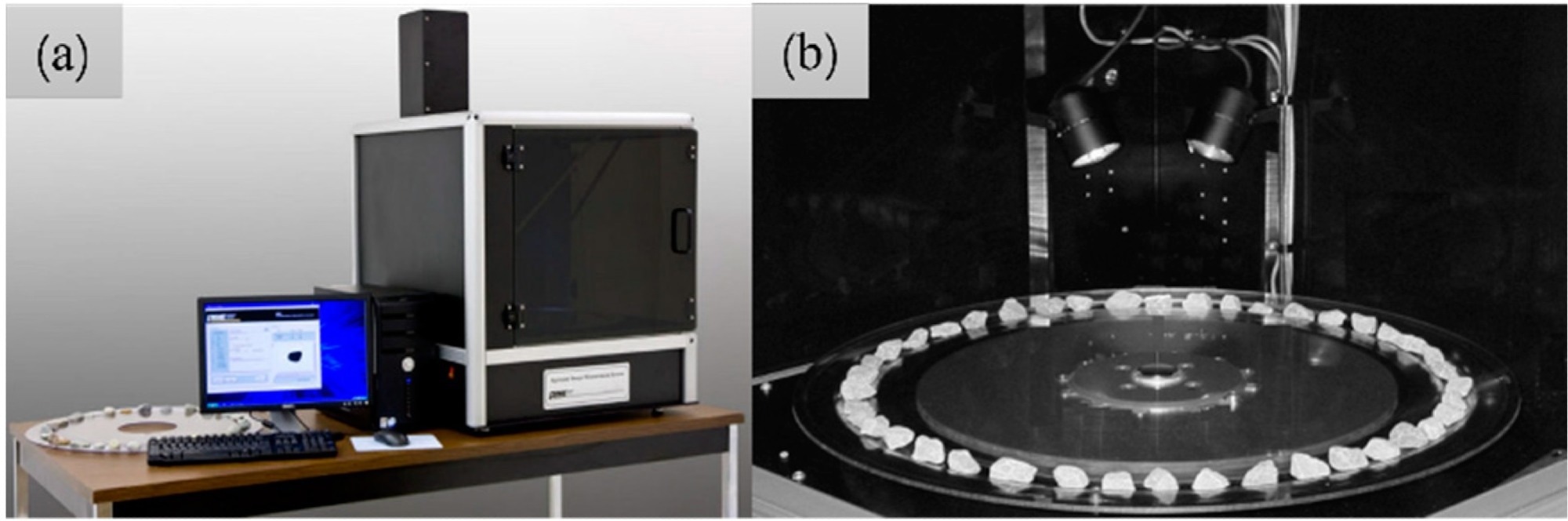

In the present study, the researchers used five kinds of manufactured sand to obtain their particle shape parameters with the help of digital image processing (DIP) and aggregate image measurement systems (AIMS). The team prepared two mixed proportions of concrete consisting of cement, fly ash, re-crushed stone, MS, water, and a superplasticizer.

Six parameters for the particle shape were assessed, including angularity, aspect, convexity, regularity, roundness, and fractal dimension. The angularity, which is the average change in the gradient vectors, was characterized by AIMS. The DIP method employed sieving, clicking photos from different directions, binarizing each image using photoshop, and obtaining the parameters using image pro plus.

The concrete was tested for slump flow following GB/T50080-2016. The compressive strength was measured in accordance with the Chinese standard GB/T50081-2002, while the durability, shrinkage, and chloride penetration resistance were measured following the GB/T50082-2009 standard. These performance parameters were then correlated with the shape parameters of the manufactured sands.

Gradation curves of six sands. Image Credit: Wu, J et al., Materials

Study Results

The team observed that the particle size of MS had a considerable impact on its angularity, and particle sizes ranging from 0.075-0.15 mm have minimum angularity. The angularity values of the five types of MS were higher than the minimum values, and the increase in angularity contributed to a downward trend in concrete workability. The increased specific surface area due to the irregular shape increased the interlocking effect as well as the frictional resistance between aggregates, and further reduced the concrete’s fluidity. This property also contributed to an improvement in the compressive strength of the concrete.

Furthermore, particle shapes had a greater effect on the concrete’s workability at a low water-cement ratio, which can be increased to improve the compatibility with poorer particles. It was also noted that particle defects can be reduced by increasing the cementitious material, which enriches the slurry in concrete and makes up for the effects of poor manufacturing of the sand particles, thus improving the concrete strength.

Cracks in concrete occur due to drying shrinkage, the rate of which increases with age. Drying shrinkage was observed to be reduced with additional cementitious materials. This prevented the volume deformation of the concrete due to an increase in the hydration products at various ages. The difference in fractal dimension was too minuscule for the particle shapes to be distinguished, and as a result, the fractal dimension was discarded from the correlation analysis.

Aggregate image measurement system (a) and aggregates being tested (b). Image Credit: Wu, J et al., Materials

Conclusions

To summarize, the angularity of MS can be significantly impacted by the size and type of the MS particles, which has a significant impact on concrete performance. The negative impacts of poor particle shape can be minimized by altering the water-cement ratio or the cementitious material amount. The compressive strength and slump display decent correlations with the morphological parameters of the particles. However, the shape of the MS did not affect concrete durability.

Moreover, particle shape parameters measured using a single projection had extensive variation and hence were ineffective in accurately determining the shape of the MS. The accuracy can be increased with additional numbers and directions of the projections.

Since concrete performance is greatly impacted by the particle shape, morphological characteristics of the MS require accurate understanding to optimize the concrete mix designs which will be beneficial for construction, the sustainable use of raw materials, and reduction in the solid waste generated. Thus, the authors recommend incorporating particle shape evaluation in the standardization of aggregates.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Wu, J.; Shen, W.; Zhao, D.; Wu, M.; Yu, Z.; Zhao, Z.; Li, Z.; Wu, D.; Sun, J. Particle Characterization of Manufactured Sand and Its Influence on Concrete Properties. Materials 2022, 15, 4593. https://www.mdpi.com/1996-1944/15/13/4593