By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.Jul 4 2022

By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.Jul 4 2022In an article recently published in the open-access journal Materials, researchers discussed the gel evolution of green geopolymers based on copper tailings in marine environments.

Study: Gel Evolution of Copper Tailing-Based Green Geopolymers in Marine Related Environments. Image Credit: AYA images/Shutterstock.com

Background

An amorphous substance with a three-dimensional (3D) microstructure is called a geopolymer. Although there are other specific applications of geopolymers that are also interesting, such as the synthesis of waste-based materials into marine concrete geopolymers, these materials are primarily studied in the application of green concrete materials for the replacement of ordinary Portland cement (OPC) material.

Marine concrete is more susceptible to damage from physical pressures and chemical corrosions than regular concrete. Due to its greater mechanical properties and higher resistance in the maritime environment than OPC concrete, the geopolymer has garnered considerable attention.

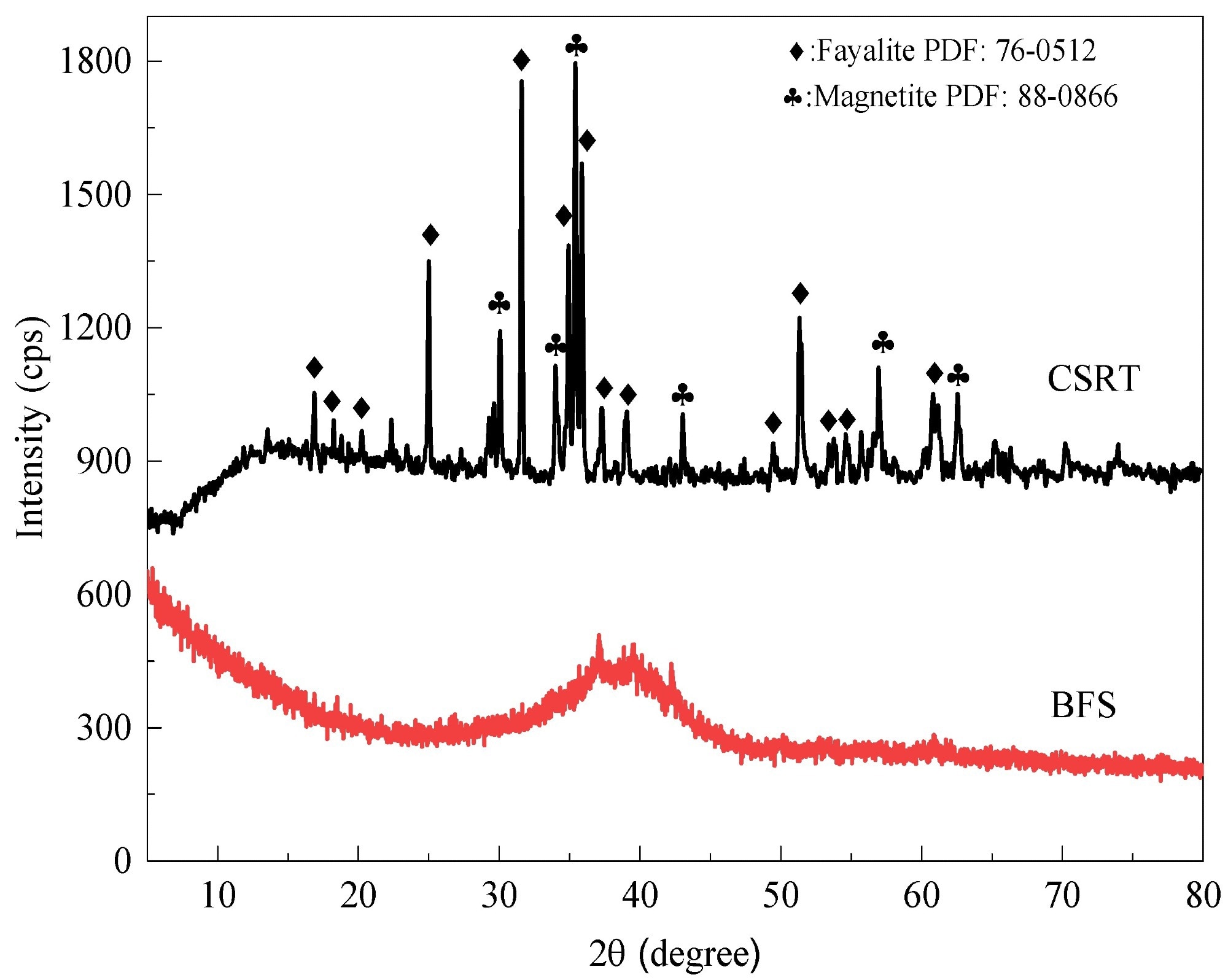

XRD patterns of the CT and BFS. Image Credit: Li, J et al., Materials

Prior research has shown that aluminosilicate minerals and industrial wastes fly ash and slag may significantly increase the compressive and freezing resistance of the geopolymer, with slag outperforming fly ash in both tests. However, the enormous number of tailings and slag could have negative effects on the ecosystem.

Reprocessing the tailings and slag is therefore urgently required to lessen their negative consequences. The mechanisms of their geopolymerization and the variations in their microstructures under diverse exposure settings, particularly the natural sea environment, have been the subject of recent studies. In order to create enhanced marine concrete, it is useful to examine the gel evolution and microstructure variation of the geopolymer under varied natural settings.

About the Study

In this study, the authors investigated the green geopolymers made from copper tailings as they evolved as gels in various conditions, including air, deionized water, freeze-thaw cycles, seawater, and carbonization. Compressive strength testing, nuclear magnetic resonance, X-ray diffraction, scanning electron microscopy, and Fourier-transform infrared spectroscopy were used to analyze the materials' mechanical characteristics and microstructures.

The team created the geopolymer by using copper tailings (CT) and blast furnace slag (BFS). An effort was made to investigate the geopolymerization process and viability of using a mine-tailings-based geopolymer as marine concrete.

The researchers investigated the evolution of the mechanical properties and microstructure of mine-tailings-based geopolymer concrete in different marine-related environments and prepared green marine geopolymer concrete using two solid wastes, BFS and CT, by geopolymeric reaction technology.

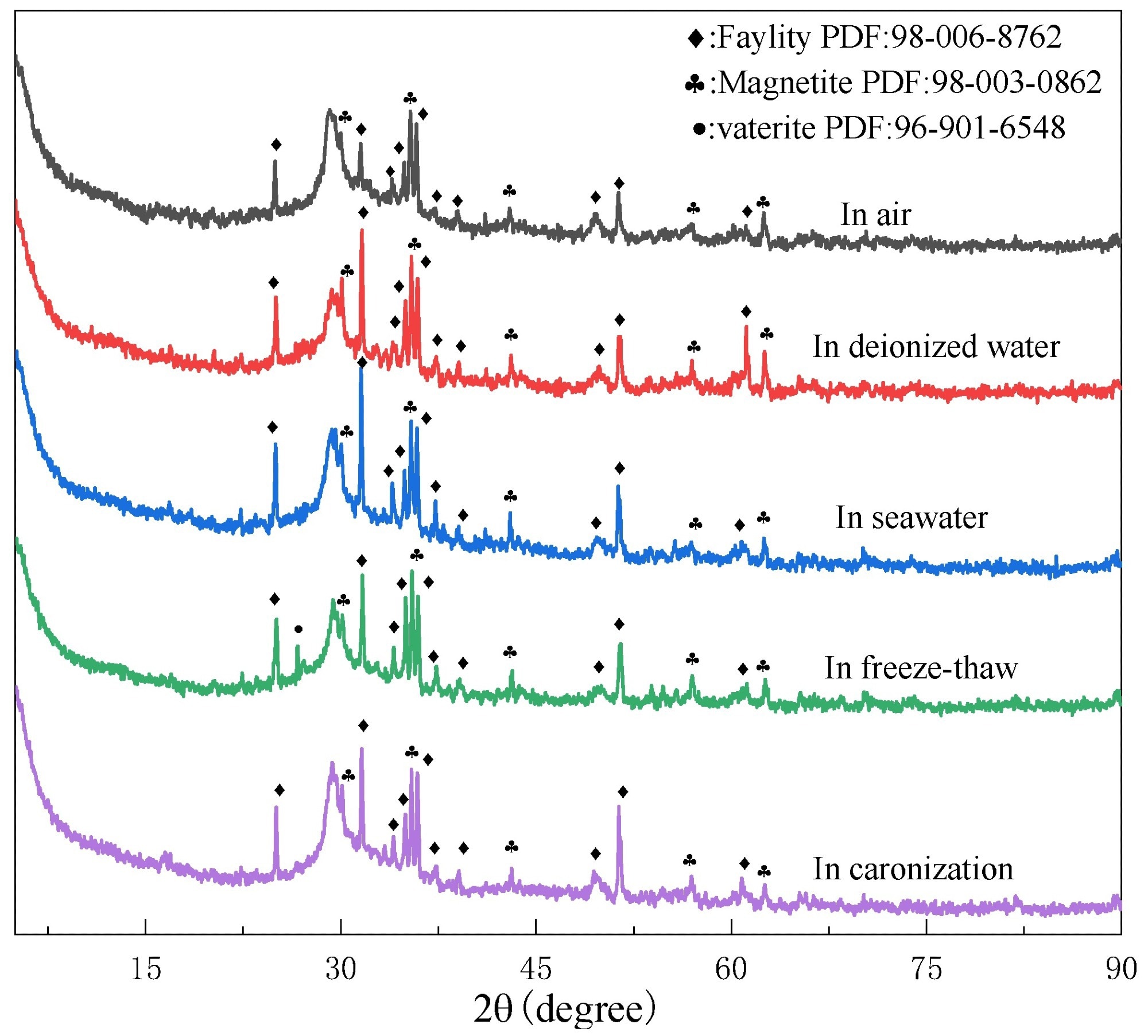

XRD patterns of geopolymers prepared with 60% BFS that underwent different exposures for 28 days. Image Credit: Li, J et al., Materials

Observations

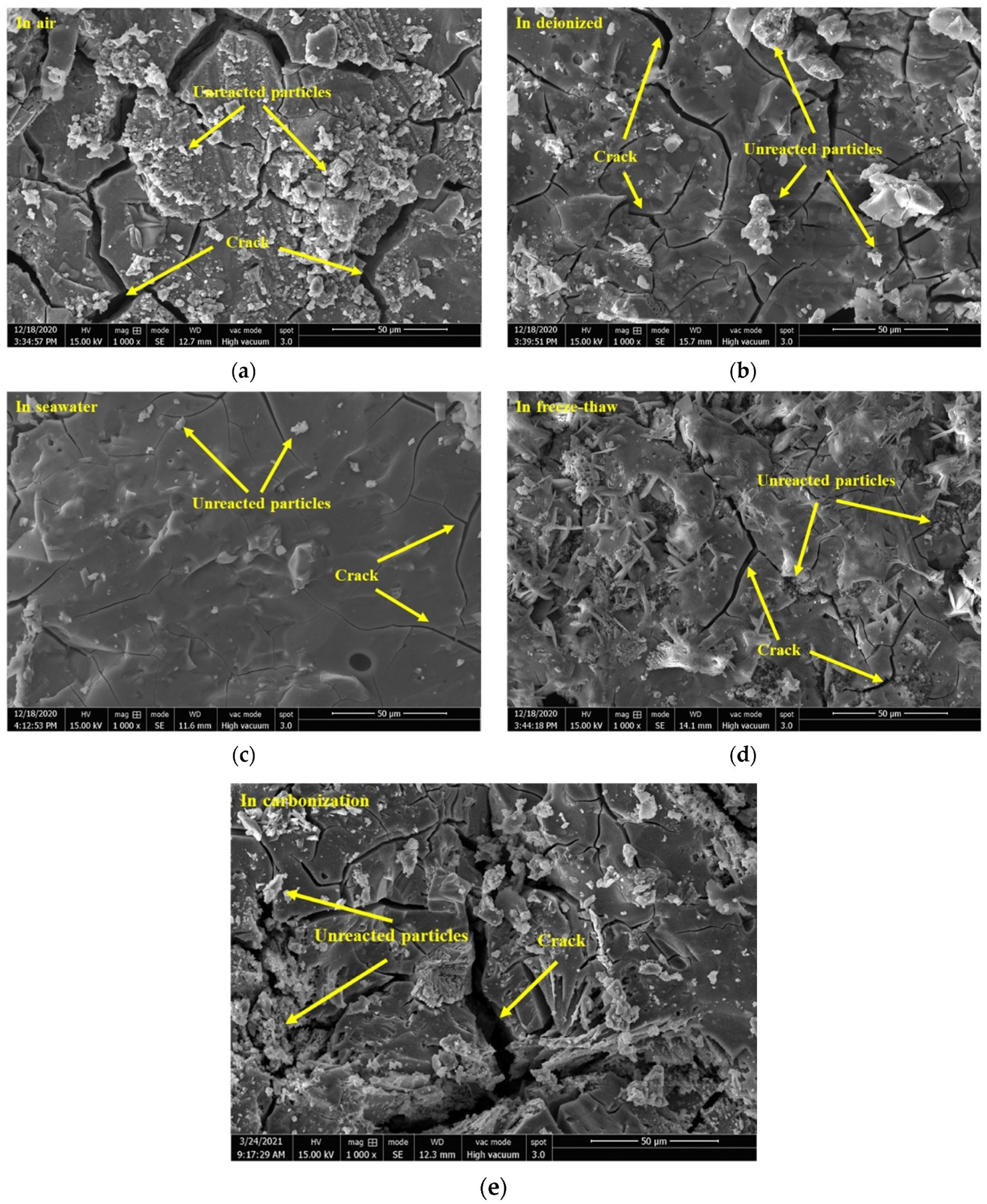

When the BFS content was 60%, the anti-freeze-thaw effect was superior to that of the three samples with varying BFS contents. In contrast to the 7-day freeze-thaw cycle, the 14-day geopolymer developed edge peeling and cracks. On the other hand, all the blocks collapsed, and the geopolymers revealed an unconsolidated matrix after 21 days of cure. In the geopolymer subjected to the carbonation environment, Q4 (1Al), Q4 (2Al), and Q4 (0Al) vanished, whilst the proportion of Q0 and Q1 increased.

The Si sites in the silicate monomers, i.e., Q0, and silicate dimmer, such as Q1, were 20.11 %, 35.45%, and 9.54 %, respectively, for the geopolymers exposed to deionized water, air, and seawater.

The Si sites in the C-(A)-S-H and N-A-S-H gel were 64.55 %, 79.89 %, and 90.46 %, respectively. The stretching vibrations of the OH and H-OH bonds in free water, which correspond to the adsorbed H2O in geopolymers, were responsible for the absorption maxima at 3440 cm-1 and 1650 cm-1, respectively. The asymmetric stretching of the O-C-O bonds in CO32- groups, which occurred as a result of carbonation during the geopolymers' curing and exposure processes, was attributed to the absorption peak at 1420 cm-1.

In contrast, exposure to the carbonization environment was found to weaken the gel evolution and reduce the cross-linking degree of the sodium aluminosilicate hydrate (N-A-S-H)gel structure, which led to a decrease in compressive strength.

Deionized water and natural marine water exposure facilitated the evolution degree of geopolymers and improved their compressive strength. The expansion brought on by crystallization in the geopolymer produced the worst damage in the geopolymer exposed to the freeze-thaw cycle. These findings were crucial and helpful for understanding how gel formed in varied maritime conditions and could encourage research towards green concrete.

SEM images of the geopolymers prepared with 60% BFS subjected to different exposure. Image Credit: Li, J et al., Materials

Conclusions

In conclusion, this study examined the gel development of a geopolymer based on CT in a marine setting. It was discovered that both deionized water and exposure to natural seawater improved geopolymer development, with the seawater showing a stronger promotion impact. The geopolymer's compressive strength was boosted as a result of increased gel formation. The N-A-S-H gel nanostructure's cross-linking level dropped as a result of the carbonization environment exposure, weakening the gel evolution and lowering compressive strength.

Due to the expansion brought on by crystallization within the geopolymer, the geopolymer subjected to the freeze-thaw cycle showed the most severe degradation. On the other hand, geopolymer concrete exhibited exceptional qualities in locations that were related to the sea.

The authors mentioned that this study offered the opportunity to convert solid waste from ordinary disposal and consumption and the low-value-added making of brick into a high-value utility, as well as the practical application of geopolymer concrete in coastal breakwaters and other constructions.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Li, J., Yang, L., Rao, F., et al. Gel Evolution of Copper Tailing-Based Green Geopolymers in Marine Related Environments. Materials 15(13) 4599 (2022). https://www.mdpi.com/1996-1944/15/13/4599