Reviewed by Alex SmithJul 25 2022

The majority of present-day energy storage systems (ESSs) have started to utilize lithium-ion batteries (LIBs), with the greatest technology maturity among the secondary batteries.

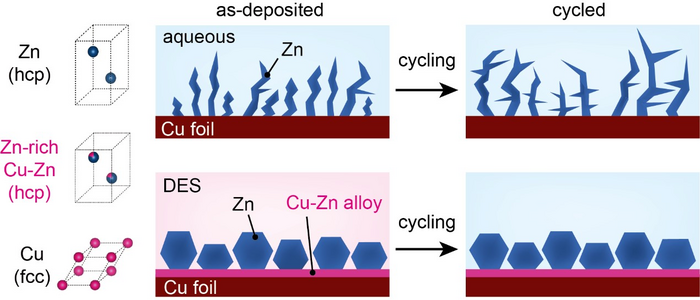

Unlike zinc particles, which are irregularly formed in a conventional aqueous electrolyte and induce corrosion, zinc grown in a DES solution is tight and uniform and maintains a stable structure even after charging and discharging in an aqueous electrolyte. Image Credit: Korea Institute of Science and Technology (KIST)

Unlike zinc particles, which are irregularly formed in a conventional aqueous electrolyte and induce corrosion, zinc grown in a DES solution is tight and uniform and maintains a stable structure even after charging and discharging in an aqueous electrolyte. Image Credit: Korea Institute of Science and Technology (KIST)

However, it is argued that due to the risk of fire, these are inappropriate for ESSs, which store significant amounts of electricity. The unpredictability of the international supply of raw materials to build LIBs has also become a critical concern.

On the other hand, aqueous zinc-ion batteries (AZIBs) tend to utilize water as the electrolyte, which essentially prevents battery ignition. Moreover, the cost of zinc, the raw material, is just one-sixteenth of that of lithium.

The research group headed by Dr. Minah Lee at the Energy Storage Research Center in the Korea Institute of Science and Technology (KIST; President Seok-Jin Yoon) reported that they had been successful in coming up with a technology for manufacturing the so-called “high-density zinc metal anodes,” which is primary to commercializing AZIBs.

This manufacturing technology has been anticipated to serve as a catalyst for the huge production of AZIBs since zinc metal anodes, along with high energy density and long lifespan, could be generated via an easy electroplating process by making use of an environmentally-friendly and affordable solution.

In theory, since AZIBs tend to use two electrons per ion, they are beneficial regarding volumetric energy density compared to alkali metal-ion batteries. If the zinc metal’s capacity utilized as the anode for making the battery does not surpass twice that of the cathode, it is possible to understand an energy density that is similar to that of the LIBs commercialized at present.

Additionally, even if the zinc metal’s capacity is five times greater than that of the cathode, it is still competitive because it is comparable to sodium-ion batteries, which are garnering interest as the next generation of batteries due to their low price and abundant supply of raw materials.

But zinc metal anodes tend to limit the energy density and lifespan of AZIBs due to the uneven growth of nanoparticles at the time of the battery operation.

In the anode, a low zinc metal particle density and a large surface area expedite corrosion with the electrolyte, thus draining the electrolyte and the active zinc metal.

Current studies normally utilized zinc metals that were nearly 20 times thicker compared to what was needed to neutralize the lifespan limitations; paradoxically, this resulted in an unavoidable decline in energy density and price competitiveness, the highest strengths of AZIBs.

The team headed by Dr. Minah Lee at KIST regulated the microstructure of zinc metal anodes to decrease the prevalence of the side reactions that induce the drop in energy density and also the lifespan of AZIBs.

A deep eutectic solvent (DES) solution has been adopted by the research group, which could be synthesized easily at room temperature to build compact zinc anodes. This DES solution is made of choline chloride and urea blended at a mole ratio of 1:2; the mixture becomes a liquid complex with a melting point of 12 °C.

The scientists verified that a zincophilic copper–zinc alloy layer freely develops between the copper and zinc current collectors inside the DES. This allows high-density zinc particles to grow.

The scientists were successful in making use of this breakthrough to come up with an electroplating process that enables zinc metals to grow in a dense and even manner in the eco-friendly and affordable DES solution.

The application of the manufactured zinc metal anode to an aqueous zinc battery system displayed that the corrosion reactions are suppressed in an effective manner. Also, the capacity has been retained at over 70% after more than 7000 charges and discharges were repeated.

This outcome is unusual compared to those of similar present studies that used thin zinc, and the values that were far surpassed the charging and discharging lifespans (1000 to 2000 times) of commercial LIBs.

We were able to develop a core technology for commercializing AZIBs that can solve the fire safety issue of ESSs, which is the biggest obstacle to the provision and expansion of renewable energy.

Dr. Minah Lee, Korea Institute of Science and Technology

Lee added, “We expect that this compact zinc anode manufacturing technology will open the way for the mass production of AZIBs by combining a particularly economical and eco-friendly DES solution with an electroplating process already widely used throughout the industry.”

Journal Reference:

Kwon, M., et al. (2022) Stimulating Cu–Zn alloying for compact Zn metal growth towards high energy aqueous batteries and hybrid supercapacitors. Energy & Environmental Science. doi.org/10.1039/D2EE00617K.