Scientists at the National Institutes of Health (NIH) and Duke University have been using chips and pressure-driven pumps from Dolomite Microfluidics to develop and optimize a microfluidic flow-focusing technology (MFFT) platform. This approach was adopted as a high throughput method of generating monodisperse, droplet-based compartments to encapsulate individual phage clones and achieve non-competitive, uniform amplification of millions of clones with differing growth characteristics.

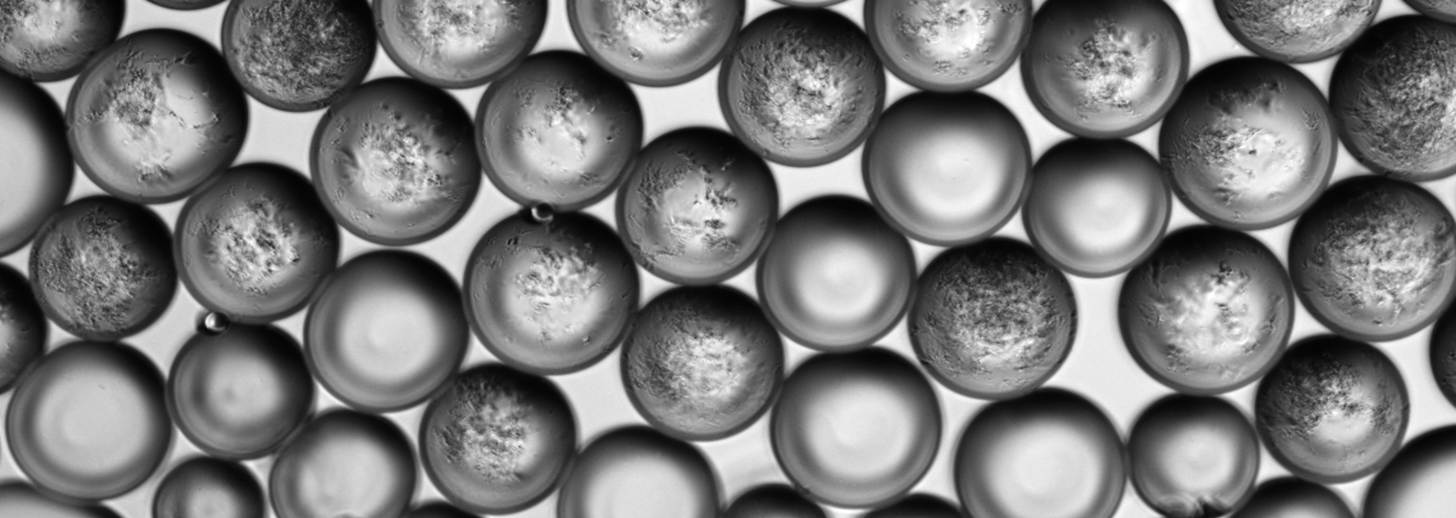

Image Credit: Dolomite Microfluidics

Dr Laurel Coons, a researcher at NIH and Duke University, explained: “Phage display is a widely used research and drug discovery technique for creating and screening highly diverse peptide libraries to identify ligands for any target. Uniform amplification is important for creating multiple copies of genetically identical phage, but clones that have a growth advantage or amplify fast make this process difficult to achieve. We found that using microfluidics could eliminate this growth-based competition, ensuring the selection of binding clones is driven only by the binding strength of each clone for the target.”

“We started with syringe pumps to demonstrate proof of concept, but encountered several problems and, after establishing a relationship with Dolomite Microfluidics in 2011, we soon realized that pressure-driven pumps are a pivotal part of generating highly stable droplets. Dolomite Microfluidics offered immediate and responsive assistance, from understanding the specific challenges during the development process, to providing suggestions and technical advice. After solving these issues, we were able to further enhance our MFFT platform by using a custom-made seven-junction, two-reagent chip, which maximized performance for higher throughput applications and enabled generation of droplets with volumes as small as 564 pl. This set-up allowed efficient, uniform amplification of complete phage libraries, and permitted the production of more than 10,000 stable monodisperse microdroplets per second.”