In a paper recently published in the journal Materials, researchers aimed to demonstrate the contribution of recycled cement from concrete waste (RCC) in reducing the cement industry’s environmental impact through a comparative life cycle assessment (LCA) of the air clean (ACM), dry (DM), and wet (WM) methods as well as ordinary Portland cement (OPC).

Study: Life Cycle Assessment of Thermoactivated Recycled Cement Production. Image Credit: Maksim Safaniuk/Shutterstock.com

Background

The release of greenhouse gases from human and natural activities is influencing the global warming felt around the world. Global warming has an impact on people all over the world, and gases produced by both natural and human activity are thought to be the cause of it, thanks to their greenhouse effect. Parallel to this, human activities produce a significant number of residues, which also contribute substantially to the deterioration of the environment. CO2 comprises about 80-90% of the total emissions in cement production.

Overall, the total CO2 contributed by cement production to annual global emissions is about 8%. Major improvements must be implemented by the cement industry in its manufacturing processes in order to achieve the goal of carbon neutrality. The thermoactivated recycled cement (RC), an eco-efficient, low-carbon cement, could be a favorable alternative to the existing carbon-intensive binders like OPC.

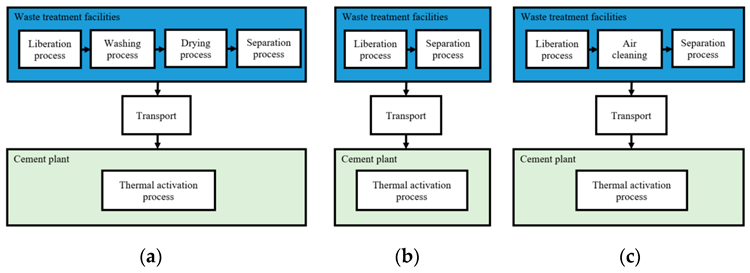

Schematic representation of the different production phases of RCC production through: (a) Wet method; (b) Dry method; (c) Air clean method. Image Credit: Real, S et al., Materials

About the Study

In the present study, the team used the SimaPro 9 software and assessed the RCC’s environmental performance in comparison to OPC with a “cradle-to-gate” method. The guidelines of EN 15804 were followed to carry out the life-cycle inventory for the product stage, which included electricity, materials, and fuels, along with waste treatment and water and air emissions.

The three production processes considered for the LCA of RCC depended on the work required for the separation process, particularly material cleaning before magnetic separation. The LCA analysis was split into 11 groups through environmental impact analysis.

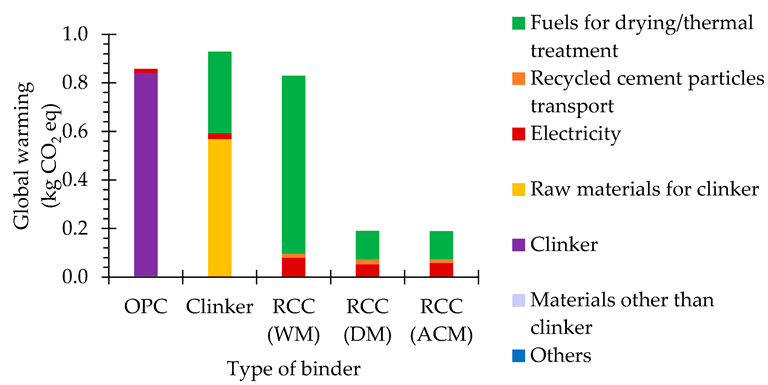

Global warming potential of different types of binder. Image Credit: Real, S et al., Materials

Observations

Although RCC ACM consumed marginally greater electricity compared to RCC DM, this contribution to the impact categories was offset by the higher purity exhibited by the RCC ACM particles. Overall, the potentials of abiotic depletion of both RCC ACM and RCC DM were significantly below those of OPC. Moreover, RCC ACM and RCC DM showed considerable potential in the effective reduction of the global warming potential than OPC. On the other hand, there was an insignificant contribution of RCC WM in the global warming potential reduction as RCC WM involved the concrete waste’s washing and drying prior to the magnetic separation.

In comparison to OPC, both RCC ACM and RCC DM had a positive effect in reducing the depletion of the ozone layer. RCC WM, yet again, due to the washing and drying involved in the separation and liberation process, contributes substantially to increasing the ozone layer depletion potential more than that of the OPC. Furthermore, RCC ACM and RCC DM exhibited a valuable influence in reducing human toxicity, as well as having better terrestrial, freshwater, and marine aquatic ecotoxicity potentials than OPC. Conversely, there was no positive effect shown on these potentials by RCC WM.

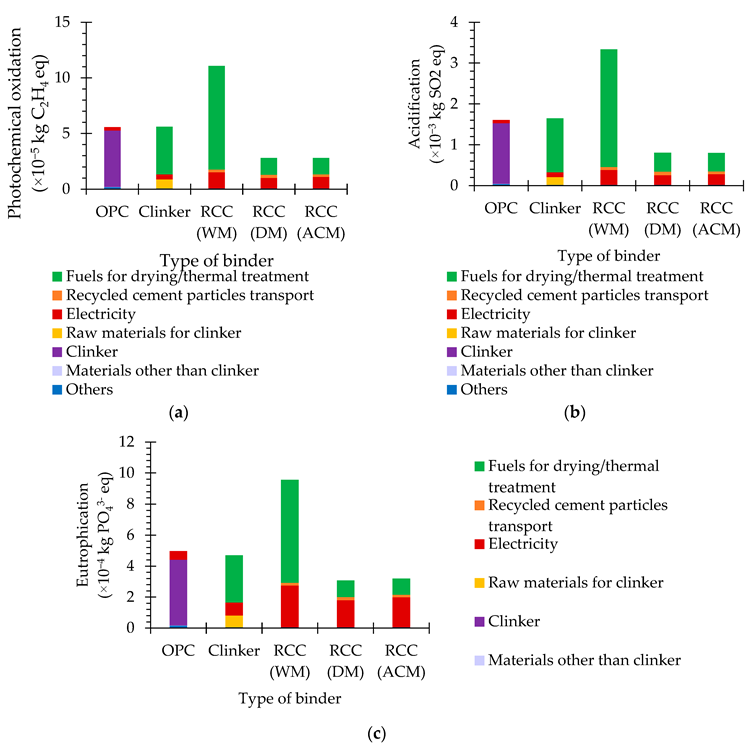

Additionally, in terms of photochemical depletion, RCC ACM and RCC DM exhibited a certain contribution than OPC. Further contributions were made in the categories of eutrophication and acidification potentials. Considering a constant thermal activation efficiency irrespective of the material’s purity level implied that a part of the RCC’s reactive components varied with the production process.

Therefore, the LCA results had been corrected for a more precise comparison between the binders (RCC DM, RCC ACM, and RCC WM). This was carried out through the division of the results by the LCA results of the RCC for the various methods were corrected by dividing them by the binder’s corresponding purity degree. The RCC WM’s purity was identical to that of RCC ACM. However, despite RCC DM requiring marginally lesser electricity compared to RCC ACM, the RCC WM’s purity was significantly lower than that of RCC ACM.

Photochemical oxidation (a), acidification (b) and eutrophication (c) potentials of different types of binder. Image Credit: Real, S et al., Materials

Conclusions

To summarize, the researchers determined that the RCC WM would not be a suitable option for OPC, especially due to the amount of electricity and fuel necessary for particle washing and drying prior to magnetic separation. Conversely, RCC ACM and RCC DM were established to be assuring options to OPC and RCC WM, with an appropriate drop in all impact groups.

Comparing the RCC ACM and RCC DM on the basis of the binder’s cement content, RCC ACM exhibited the least environmental impacts. However, the research results indicated that the possible feasibility of RCC could be utilized as partial OPC replacement in several applications. Moreover, the produced RCC volumes from the annual concrete waste created would be insufficient to meet the cement demands within the given time frame.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Real, S.; Sousa, V.; Meireles, I.; Bogas, J.A.; Carriço, A. Life Cycle Assessment of Thermoactivated Recycled Cement Production. Materials 2022, 15, 6766. DOI: https://doi.org/10.3390/ma15196766