By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.Oct 25 2022

By Surbhi JainReviewed by Susha Cheriyedath, M.Sc.Oct 25 2022In an article recently published in the journal ACS Energy Letters, researchers discussed the utility of silicon as an anode for solid-state batteries.

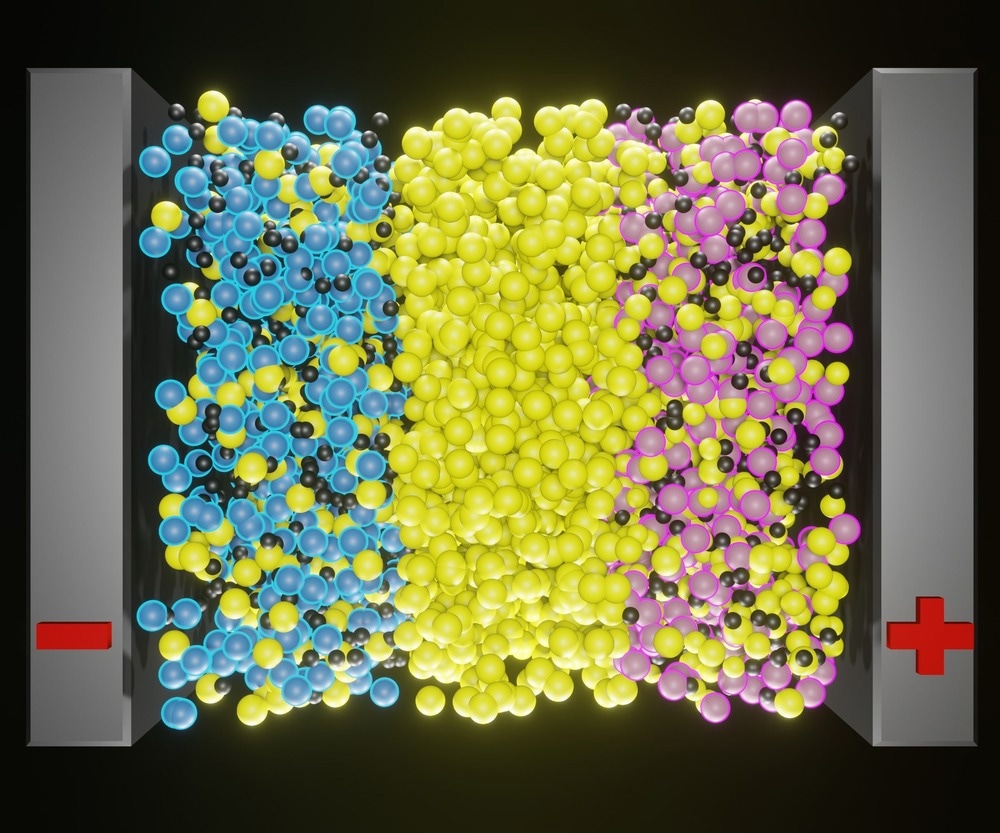

Study: Silicon as Emerging Anode in Solid-State Batteries. Image Credit: Love Employee/Shutterstock.com

Background

The market for electrical energy is expanding quickly as a result of the popularity of portable electronics and electric cars, as well as the expanding importance of renewable energy sources. Intense research is being conducted on high-capacity materials since current lithium-ion batteries (LIBs) based on liquid electrolytes are likely unable to meet the rising demand for energy and power density.

Solid-state batteries (SSBs), which have a simpler cell design and an anode-free arrangement, have been thought of as a potential next-generation storage concept for a few years. Pure lithium metal anodes in SSBs stand out for having the highest specific capacity and the lowest potential. However, their practical use in SSBs is still constrained by interface instability, the production of solid electrolyte interphase (SEI), a low critical current density, and separator penetration by lithium dendrites.

Silicon has emerged as a promising anode material for SSBs. Building silicon nanostructures, combining them with other alloy composites, and reducing silicon pulverization under stress with strong binders are all useful methods for improving their potential. To stabilize the SEI, liquid electrolyte additions have been extensively researched. Solid electrolytes (SEs), in contrast to typical liquid-cell topologies, appear to be able to reduce the problems brought on by the significant volume change of silicon. It is important to give this some further study, as silicon anodes might offer a practical way to attain high energy density and long cycling stability in SSBs.

About the Study

In this study, the authors discussed a viewpoint for SSB cells with high energy density and outlined current successes and remaining problems for the use of silicon anodes in SSBs. The electro-chemo-mechanical behavior and microstructure optimization of powder-pressed pellet-type cells, three different cell-type thin-film cells, and sheet-type pouch cells, each with a distinctive silicon anode, were discussed. Research on silicon anodes in SSBs related to the measurement of their partial ionic/electronic conductivity, determining their interfacial stability, and analyzing their chemo-mechanical stability, was elucidated.

The team provided a brief overview of the evolution of silicon anodes in SSBs during the last 15 years. Three different forms of silicon anodes, powder-pressed, thin-film, and sheet-type silicon anodes, were distinguished by their typical advantages and disadvantages, from knowledge of their innate characteristics to the logical design of anodes for real-world uses. Different silicon anode types were used in many SSBs, and each one had its problems and difficulties.

The researchers investigated the effects of numerous variables, such as silicon powder characteristics and electrochemical test conditions on the electrochemical performance of silicon anodes. The significance of thin SE separators and high-loading electrodes was highlighted by comparing the energy density of SSBs with either silicon or lithium anodes. The current silicon anode problems were highlighted and potential future research topics for cells with various SEs were demonstrated.

Observations

Recent studies showed that SSBs based on 2D-type 10 μm thick pure silicon anodes and sulfide SEs could attain long cycling lives, high Coulomb efficiencies, and outstanding rate performance. The usage of a compact silicon anode layer rather than a composite anode resulted in a simple layered architecture with a 2D SEI, which decreased irreversible lithium loss and generated less SEI degradation per SE volume.

For practical applications, active mass loadings exceeded 4 mAh cm-2, which equated to a silicon layer thickness of more than 10 μm. When silicon thin-film anodes were formed to a thickness greater than 1 μm, the critical SE|Si interface contact loss and inadequate ion/electron transport occurred during the lithiation/delithiation process. During repeated cycling, polymer SEs could efficiently reduce local stress at the 2D Si/polymer interfaces. In comparison to a rigid interface based on ceramic SEs, a flexible interface based on polymer SEs demonstrated superior stability. High energy density could be attained by SSBs with a sheet-type NCM cathode, a silicon anode, and a thin polymer SE separator. However, contemporary polymer SEs exhibited low ionic conductivity and poor oxidation stability at ambient temperature.

Although certain research in the literature on lithium anodes recorded high stack pressures greater than 100 MPa to sustain interface contact, which was far from the comparatively low stack pressure of 1 MPa acceptable in actual applications, the yield strength for bulk lithium anodes was 1 MPa. In comparison, completely lithiated silicon had a yield strength of up to 430 MPa.

Incorporating silicon particles into a softer matrix was one method to reduce applied pressure. The majority of silicon used as anode material was undoped, and seldom work on modified silicon was published.

Conclusions

In conclusion, this study provided an overview of current advancements, characterization, and testing of various silicon anode types used in SSB cells, including thin-film Si anodes, power-pressed composite Si anodes, and sheet-type Si anodes. The effects of numerous parameters, including applied stack pressure, silicon particle size, and cutoff voltage, on the performance of silicon anodes, were covered in detail.

The authors observed that several characterization approaches, including time-of-flight secondary ion mass spectrometry (ToF-SIMS), in situ X-ray photoelectron spectroscopy (XPS), and differential electrochemical mass spectrometry (DEMS), were used to reveal the mechanisms of sulfide SEs' degradation at both lithium anode and the NCM cathodes. They stated that future research should look into how coating materials on silicon particle surfaces could not only reduce side reactions but also silicon anode volume change.

More from AZoM: How are Graphene Batteries Made?

References

Huo, H., Janek, J., Silicon as Emerging Anode in Solid-State Batteries. ACS Energy Letters, 7, 4005-4016 (2022). https://pubs.acs.org/doi/10.1021/acsenergylett.2c01950

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.