Reviewed by Emily Henderson, B.Sc.Nov 1 2022

Scientists at Fudan University considered the fundamental mechanisms and new development in the discerning laser sintering of polymers. This seemed to be of great help for scientists to learn more regarding the terrific additive manufacturing method of polymer.

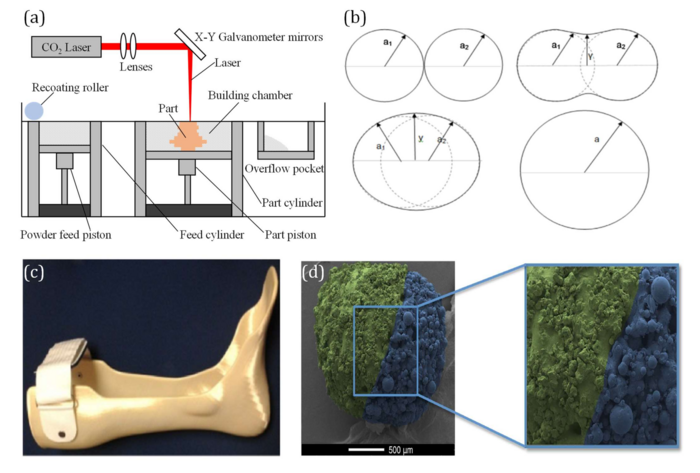

(a) Schematic diagram of the SLS process; (b) Coalescence process of two polymer particles; (c) Ankle-foot orthoses fabricated by additive manufacturing; (d) Dual selective laser sintering minitablets, the yellow regions mean the Ethyl Cellulose regions, whereas the blue regions mean the Kollicoat Instant release regions. Image Credit: By Wei Han, Lingbao Kong, Min Xu. Un

(a) Schematic diagram of the SLS process; (b) Coalescence process of two polymer particles; (c) Ankle-foot orthoses fabricated by additive manufacturing; (d) Dual selective laser sintering minitablets, the yellow regions mean the Ethyl Cellulose regions, whereas the blue regions mean the Kollicoat Instant release regions. Image Credit: By Wei Han, Lingbao Kong, Min Xu. Un

The polymer’s binding mechanism in SLS was initiated based on the Frenkel-Eshelby model while supposing that the particle radius seems constant. Furthermore, the typical applications of the SLS polymers parts have been learned, considering the pharmaceutical, biomedical, electronic applications, and so on. Eventually, future research was outlined based on the above.

Laser sintering resin is an extremely complex process because of the combination of optics, materials science, chemistry, and thermal disciplines. To obtain parts with superior physical and mechanical properties, it is necessary to deeply understand the sintering mechanism, the influence of process parameters, and the optimization of the sintering process.

Wei Han, Study Lead Author, and Professor, International Journal of Extreme Manufacturing

Laser sintered parts have been widely used in automobiles, medical devices, and daily necessities.

Lingbao Kong, Professor, Shanghai Ultra-Precision Optical Manufacturing Engineering, Research Center, Fudan University

Kong added, “However, the number of suitable SLS resins has been relatively small for a long time, and there is still a gap between the mechanical properties and density of sintered parts of some special resin materials and the bulk material. Research on new materials, sintering mechanisms, and application areas still need to be explored further.”

Professor Min Xu, Director of Shanghai Ultra-Precision Optical Manufacturing Engineering Research Center of Fudan University, said, “Compared with injection molding, extrusion molding, and other methods widely used in the industry, the efficiency of laser sintering polymer is still too low. To widely apply polymer sintering methods in the industry, innovative and efficient new sintering methods require research and attention.”

Polymer particle coalescence mechanism, new SLS polymer, high-speed polymer sintering method, post-processing of sintered polymer, and simulation of sintering process will be significantly important research in the near future.

Wei Han, Study Lead Author, and Professor, International Journal of Extreme Manufacturing

Journal Reference:

Han, W. et al. (2022) Advances in selective laser sintering of polymers, https://doi.org/10.1088/2631-7990/ac9096.