Reviewed by Emily Henderson, B.Sc.Nov 9 2022

New views have been unlocked in developing safe and affordable so-called thermoelectric materials to convert heat into electricity. This can be done with the help of easily accessible materials from safe raw materials.

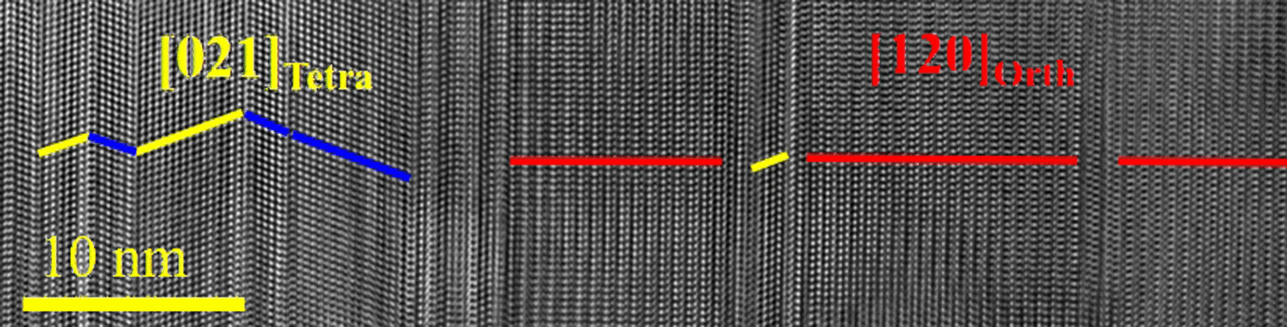

Image Credit: © Wiley-VCH, re-use with credit to 'Angewandte Chemie' and a link to the original article.

According to a new study, a synthetic copper mineral needs a complicated structure and microstructure via easy alterations in its composition. This helps to lay the basis for the preferred properties.

The study has been reported in the Angewandte Chemie journal.

The novel synthetic material is made of copper, germanium, sulfur, and manganese, and it is produced in a quite simple process, describes materials scientist Emmanuel Guilmeau, CNRS scientist at CRISMAT laboratory, Caen, France, who is the corresponding author of the study.

The powders are simply mechanically alloyed by ball-milling to form a precrystallized phase, which is then densified by 600 degrees Celsius. This process can be easily scaled up.

Emmanuel Guilmeau, Materials Scientist and CNRS Researcher, CRISMAT laboratory

Thermoelectric materials tend to convert heat to electricity. Especially, this is beneficial in industrial processes where waste heat could be reused as useful electric power. The converse method is the cooling of electronic parts, for instance, in cars or smartphones.

Materials utilized in this application must be effective, affordable, and, more than that, safe for health.

But thermoelectric devices used so far tend to use expensive and poisonous elements like tellurium and lead, providing the best conversion efficiency.

For safer alternatives to be determined, Emmanuel Guilmeau and his team have shifted to derivatives of natural copper-based sulfide minerals. Such mineral derivatives are primarily made of nontoxic and ample elements, and few possess thermoelectric properties.

Currently, the research group has successfully generated a range of thermoelectric materials displaying two crystal structures inside the same material.

We were very surprised at the result. Usually, slightly changing the composition has little effect on the structure in this class of materials.

Emmanuel Guilmeau, Materials Scientist and CNRS Researcher, CRISMAT laboratory

The team discovered that substituting a small fraction of the manganese with copper generated complicated microstructures along with interconnected nanodomains, coherent interfaces, and defects. This impacted the transport properties of the material for heat and electrons.

Emmanuel Guilmeau states that the novel material generated is stable up to 400 °C, a range well inside the waste heat temperature range of the majority of industries. He is positive that, depending on this discovery, nontoxic thermoelectric and novel cheaper materials could be designed to substitute more tricky materials.

Journal Reference:

Kumar, P., et al. (2022) Engineering Transport Properties in Interconnected Enargite-Stannite Type Cu2+xMn1−xGeS4 Nanocomposites. Angewandte Chemie. doi.org/10.1002/anie.202210600.