3D printing food could help address global food supply and nutrition issues. However, there are challenges in acclimatizing additive manufacturing to create edible materials.

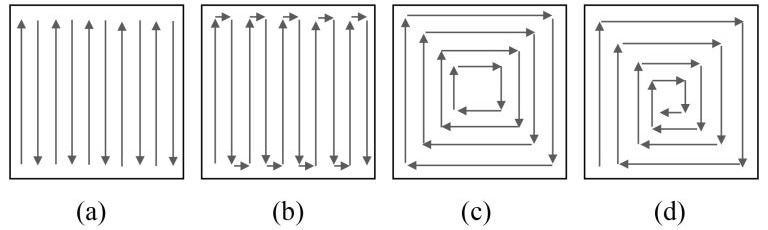

Common toolpath patterns used in additive manufacturing technologies: a) raster, b) zigzag, c) contour, and d) spiral. Image Credit: Ezgi Pulatsu and Chibuike Udenigwe

Ezgi Pulatsu and Chibuike Udenigwe of the University of Ottawa pinpoint a lot of factors that influence the print quality and shape complexity of food created with additive manufacturing in Physics of Fluids, published by AIP Publishing. Accounting for these characteristics can enhance food quality, control, and printing speed.

Food additive manufacturing entails crafting (3D shapes and geometric codes), pre-processing (food ink preparation), manufacturing (layer deposition to generate shapes), and post-processing (baking, boiling, freezing, cooking, frying, or drying). Each step provides an opportunity to create novel foods.

Modifying the printing patterns and ingredients of the initial mix or paste can have an impact on the matrix and microstructures of the food and thus its texture.

The flow of that mix is also important in additive manufacturing, and it can be encouraged or discouraged by controlling ingredients and process conditions.

Extrusion-based 3D printing is the most applicable technique for food. It involves a syringe loaded with a food paste—such as puree, dough, or frosting—being forced out of a nozzle by direct (pushing the plunger) or indirect force (compressed air).

Ezgi Pulatsu, University of Ottawa

The initial step to successful printing is to create a stable continuous flow so that designed shapes can be generated by layering stringlike material in a controllable manner.

Once a layer is deposited, we no longer want it to flow; otherwise, it will destroy the shape we created.

Ezgi Pulatsu, University of Ottawa

Post-processing, such as baking, boiling, cooking, freezing, frying, or drying, physically and chemically transforms the food’s micro- and macromolecules, resulting in a variety of textures and flavors. Simultaneously, the shape should be preserved or strictly controlled.

We also have other mechanisms of creating food structures via different 3D-printing techniques. For example, material jetting uses liquid binders deposited on powder to form self-supporting layers, and liquid inks that harden after deposition can also be used.

Ezgi Pulatsu, University of Ottawa

Creating a printing path (a series of computer-controlled movements), which is often avoided for food applications, is one way to make additive manufacturing more effective for the food industry.

“Future studies should explore the cost efficiency of different technologies in terms of build time, where shape complexity and toolpath strategies—which involve the printing path, moving head speed, and nonprinting movements—are also considered,” notes Pulatsu.

Pulatsu concludes, “Food is essential to living, and it’s becoming more critical due to the increasing global population and environmental changes. Therefore, novel foods and matrices should be designed in consultation with chefs, food scientists, and engineers, and in line with current needs.”

Journal Reference

Pulatsu, E. & Udenigwe, C. (2023). Perspectives, Analyses, and Progress in Additive Manufacturing of Food. Physics of Fluids. doi.org/10.1063/5.0137328.