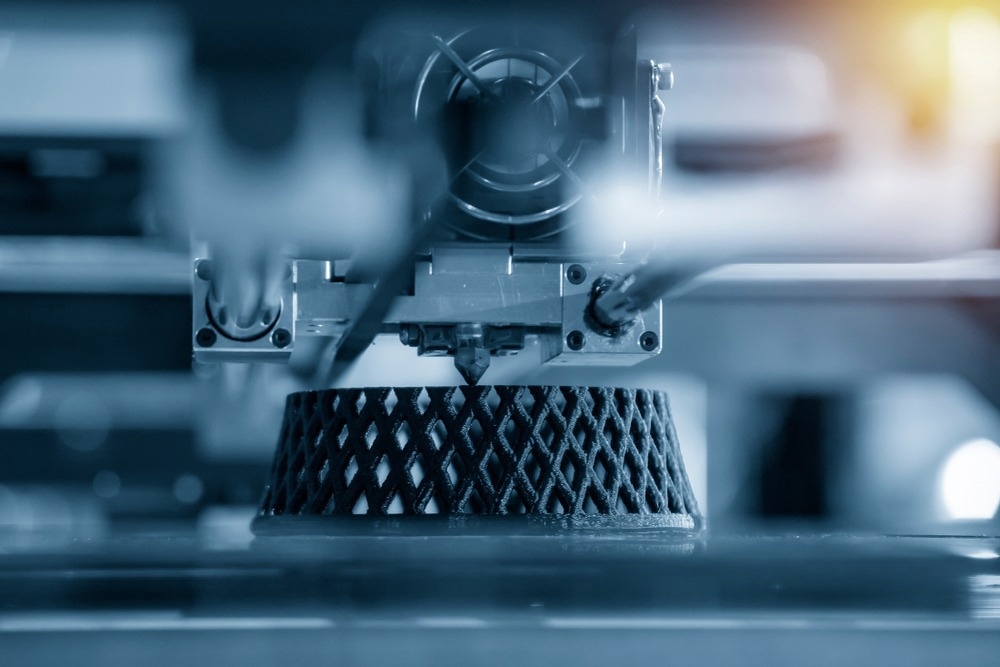

A novel method of three-dimensional (3D) printing employs ultrasound waves to produce things using acoustically cured inks. The method enables volumetric 3D printing even in opaque media or at great penetration depths, possibly even within the body. 3D printing technologies are set to change industrial processes for a wide variety of applications.

Image Credit: Pixel B/Shutterstock.com

Volumetric printing, a new 3D printing process, can build items quicker and with higher surface quality than layer-by-layer printing methods. The majority of contemporary volumetric printing processes rely on light to initiate photopolymerization in optically transparent inks.

However, light scattering by the inks, the presence of functional additives within the inks, and light-blocking by previously cured areas of the build limit the material options and build sizes that can be used, especially in configurations that need deep light penetration. Ultrasound waves can penetrate far deeper into materials than light waves and, in theory, can be used to start polymerization.

Xiao Kuang and colleagues offer deep-penetrating acoustic volumetric printing (DAVP), a novel technique for volumetric printing that employs concentrated ultrasonic waves and “sono-ink.”

The authors’ sono-ink solves some of the major problems associated with acoustic volumetric printing by forming a viscous gel that inhibits streaming flow and concurrently starts a heat-triggered polymerization utilizing an adaptive acoustic absorber that is thermally sensitive.

In testing, the scientists were able to print structures at a millimeter scale and several centimeters deep in an opaque medium rapidly using DVAP, a variety of nanocomposite materials. Kuang et al. used DAVP in minimally invasive medicine and high-speed, high-resolution tissue production as a proof of concept.

The authors show how to fabricate artificial bone and close the left atrial appendage in situ using tests conducted on ex vivo tissues that have been injected with sono-ink. Yuxing Yao and Mikhail Shapiro address the DAVP technique, its drawbacks, and its possible applications—including minimally invasive medical procedures—in a related Perspective.

Study authors Yao and Shapiro added, “It is conceivable that the running shoes of the future could be printed with the same acoustic method that repairs bones.”

Journal Reference:

Kuang, X, et. al. (2023) Self-enhancing sono-inks enable deep-penetration acoustic volumetric printing. Science. doi:10.1126/science.adi1563