Researchers at Osaka Metropolitan University are making significant progress toward the sustainable production of fumaric acid, a component of biodegradable plastics like polybutylene succinate, frequently used for food packaging, in the face of growing global concern over climate change and plastic pollution. Fumaric acid is typically sourced from petroleum. However, the researchers have successfully produced fumaric acid using carbon dioxide, renewable resources, and chemicals derived from biomass.

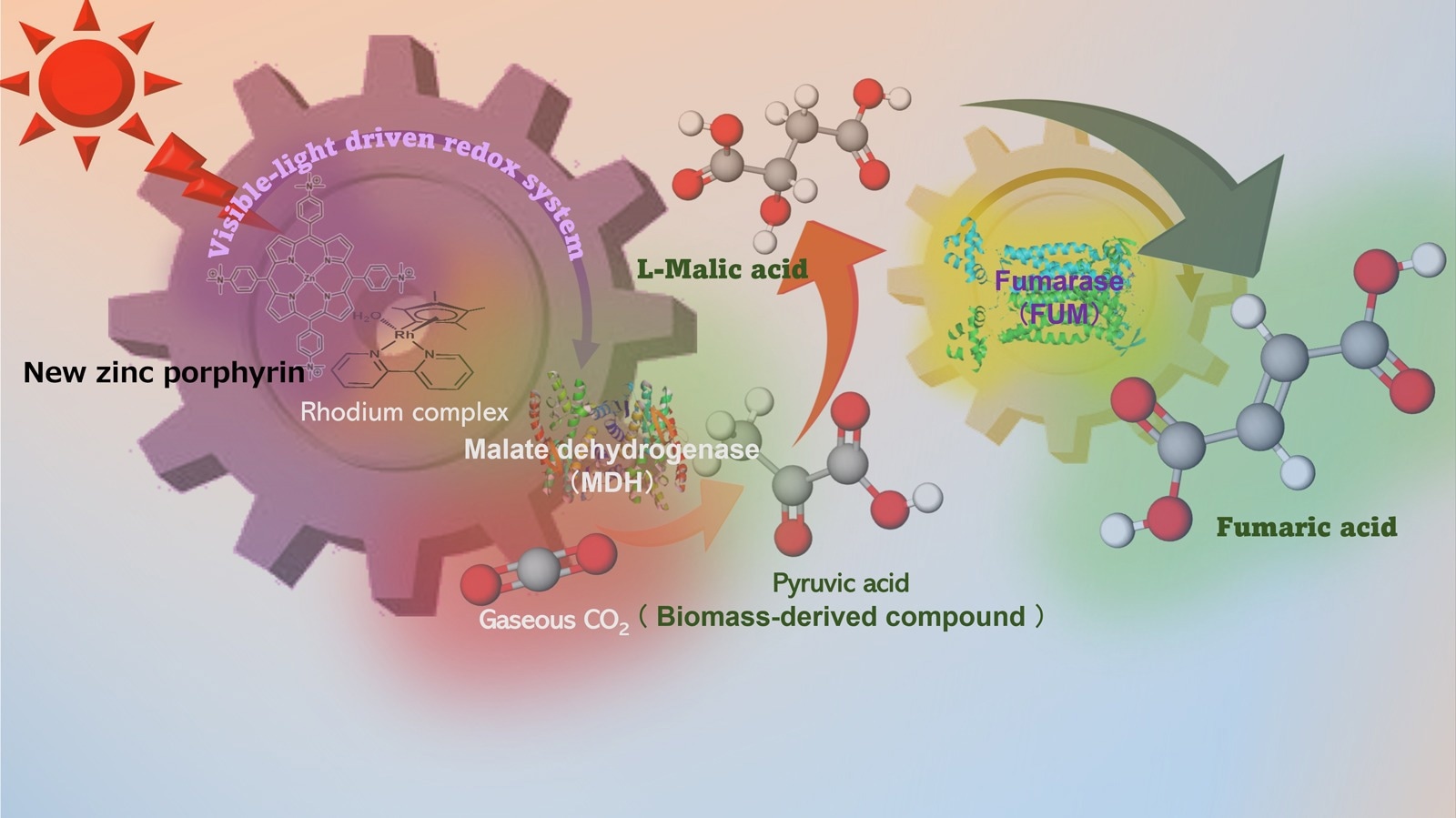

A schematic diagram of how fumaric acid is produced from carbon dioxide using solar energy. Scientists have developed a new environmentally friendly system that doubles the efficiency of fumaric acid production. Image Credit: Yutaka Amao, Osaka Metropolitan University

A schematic diagram of how fumaric acid is produced from carbon dioxide using solar energy. Scientists have developed a new environmentally friendly system that doubles the efficiency of fumaric acid production. Image Credit: Yutaka Amao, Osaka Metropolitan University

A research team from Osaka Metropolitan University's Research Center for Artificial Photosynthesis, under the direction of Professor Yutaka Amao, previously showed how to use solar energy to synthesize fumaric acid from bicarbonate and pyruvic acid, two compounds produced from biomass.

Using carbon dioxide taken straight out of the gas phase as a raw material, they successfully created fumaric acid. Still, fumaric acid manufacturing yielded a low product.

In their most recent study, which was published in Dalton Transactions, the researchers improved an artificial photosynthesis process and created a novel photosensitizer that doubles the production of fumaric acid when compared to traditional techniques.

This is an extremely important advancement for the complex bio/photocatalyst system. It is a valuable step forward in our quest to synthesize fumaric acid from renewable energy sources with even higher yields, steering us toward a more sustainable future.

Yutaka Amao, Research Center for Artificial Photosynthesis, Osaka Metropolitan University

Fund for the Promotion of Joint International Research (Fostering Joint International Research (B)) (19KK0144), Scientific Research (B) (22H01872), (22H01871), Grant-in-Aid for Specially Promoted Research (23H05404), and Institute for Fermentation, Osaka (IFO) (G-2023-3-050) provided partial funding for this study.

Journal Reference:

Takeuchi, M., et. al. (2024) An effective visible-light driven fumarate production from gaseous CO2 and pyruvate by the cationic zinc porphyrin-based photocatalytic system with dual biocatalysts. Dalton Transactions. doi:10.1039/D3DT03492E