Reviewed by Lexie CornerMar 7 2024

Researchers have made progress toward realizing solid-state batteries made of sulfur and lithium. A team of engineers at the University of California, San Diego, created a novel cathode material for solid-state lithium-sulfur batteries that is electrically conductive and structurally healable, overcoming the limits of these batteries' present cathodes.

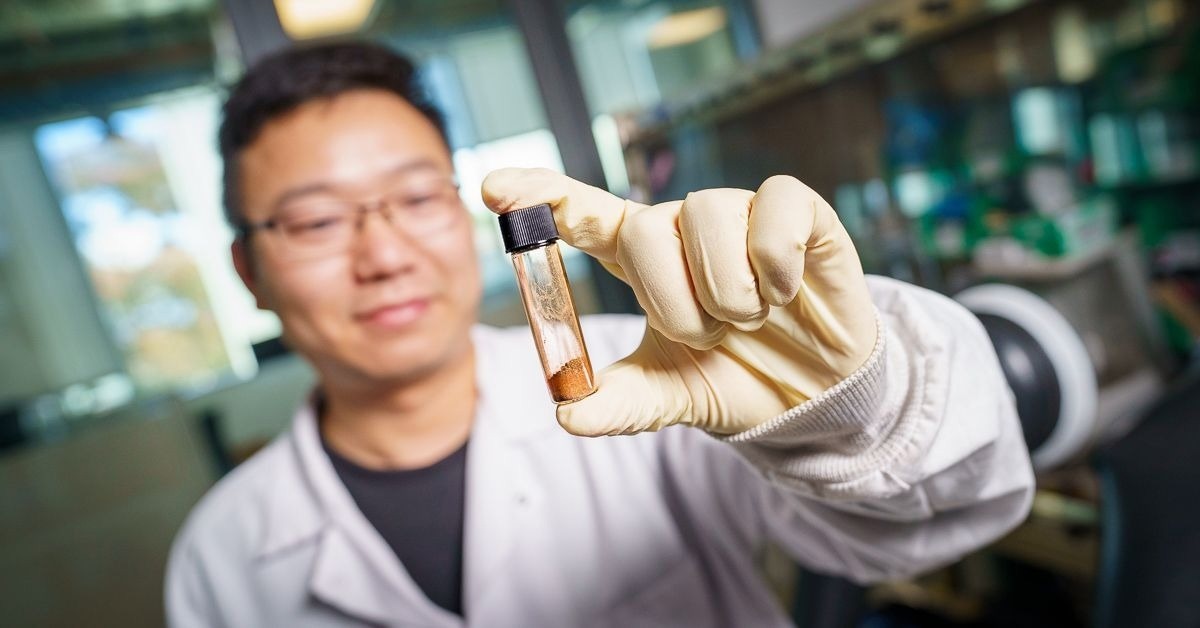

This new cathode material for lithium-sulfur materials is structurally healable and highly conductive. Image Credit: David Baillot/ University of California San Diego Jacobs School of Engineering

This new cathode material for lithium-sulfur materials is structurally healable and highly conductive. Image Credit: David Baillot/ University of California San Diego Jacobs School of Engineering

The research was published in the journal Nature.

Solid-state lithium-sulfur batteries are rechargeable batteries comprised of a solid electrolyte, a lithium metal anode, and a sulfur cathode. These batteries are more affordable and have a higher energy density than existing lithium-ion batteries, and therefore have great potential to replace them.

By storing up to twice as much energy per kilogram as traditional lithium-ion batteries, electric vehicles could travel twice as far between charges without adding weight to the battery pack. They are also more affordable and environmentally friendly due to their use of readily available, abundant materials.

However, the intrinsic properties of sulfur cathodes have historically hampered the development of lithium-sulfur solid-state batteries. Sulfur is not only a poor electron conductor, but during charging and discharging, sulfur cathodes expand and contract significantly, causing structural damage and reducing contact with the solid electrolyte.

These problems reduce the cathode’s capacity to transfer charge, jeopardizing the solid-state battery’s overall performance and lifespan.

A group led by scientists at the UC San Diego Sustainable Power and Energy Center created a novel cathode material a crystal made of iodine and sulfur—to get around these problems. The researchers significantly enhanced the cathode material’s electrical conductivity by 11 orders of magnitude by introducing iodine molecules into the crystalline sulfur structure, making it 100 billion times more conductive than sulfur crystals alone.

We are very excited about the discovery of this new material, and the drastic increase in electrical conductivity in sulfur is a surprise and scientifically very interesting.

Ping Liu, Study Co-Senior Author, Professor and Director, Sustainable Power and Energy Center, University of California

At 65 ºC (149 ºF), the new crystal material has a low melting point lower than the temperature of a steaming cup of coffee. This implies that damaged interfaces from cycling can be easily fixed by simply re-melting the cathode after the battery has been charged.

To address the cumulative damage that results from repeated charging and discharging at the solid-solid interface between the cathode and electrolyte, this feature is crucial.

This sulfur-iodide cathode presents a unique concept for managing some of the main impediments to commercialization of Li-S batteries, and Iodine disrupts the intermolecular bonds holding sulfur molecules together by just the right amount to lower its melting point to the Goldilocks zone above room temperature yet low enough for the cathode to be periodically re-healed via melting.

Shyue Ping Ong, Study Co-Senior Author and Professor, School of Nanoengineering, Sustainable Power and Energy Center, University of California

Jianbin Zhou, Study Co-First Author and a former nanoengineering postdoctoral researcher from Liu’s research group added, “The low melting point of our new cathode material makes repairing the interfaces possible, a long sought-after solution for these batteries, and his new material is an enabling solution for future high energy density solid-state batteries.”

The researchers built a test battery and repeatedly charged and discharged it to verify the performance of the new cathode material. With over 400 cycles, the battery held its stability and retained 87 % of its capacity.

This discovery has the potential to solve one of the biggest challenges to the introduction of solid-state lithium-sulfur batteries by dramatically increasing the useful life of a battery, and the ability for a battery to self-heal simply by raising the temperature could significantly extend the total battery life cycle, creating a potential pathway toward real-world application of solid-state batteries.

Christopher Brooks, Study Co-Author and Chief Scientist, Honda Research Institute USA, Inc.

The group aims to enhance cell engineering designs and increase the cell format to propel the solid-state lithium-sulfur battery technology forward.

Liu added, “While much remains to be done to deliver a viable solid-state battery, our work is a significant step, and this work was made possible thanks to great collaborations between our teams at UC San Diego and our research partners at national labs, academia, and industry.”

This research was funded in part by the US Department of Energy (DOE) Advanced Research Projects Agency-Energy and the US DOE Office of Science.

Journal Reference:

Zhou, J., et al. (2024) Healable and conductive sulfur iodide for solid-state Li–S batteries. Nature. doi:10.1038/s41586-024-07101-z