Sep 23 2016

The concept of vehicle connectivity initially focused on providing drivers with navigation assistance and emergency services, such as the features found in GM’s original ‘On Star’ product. Over the years, the idea has been expanded to integrate other in-vehicle technologies such as live traffic updates and Wi-Fi connectivity and other sophisticated features such as lane departure warnings and new blind spot alerts.

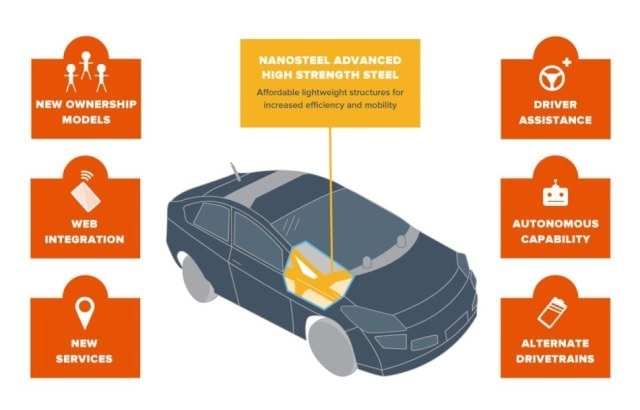

Connectivity is not only about the addition of new car feature, it has also transformed the way we think about vehicle ownership by enabling vehicle sharing services such as Uber and ZipCar.

Personal transportation is expected to transition from individual ownership to mobility services in the near future, placing huge pressure on automotive manufacturers to determine and acquire the enabling technologies. In order to accommodate this transition, automakers need to focus on new vehicle design, connectivity and safety features with contending requirements, such as affordability, fuel economy and passenger comfort.

All of these new technical features further increase the space and weight requirements of a vehicle and as a result, automakers face additional pressure to achieve fuel economy targets and efficient cabin space management. Automakers can address these challenges with the help of new materials.

NanoSteel AHSS is foundational to this design strategy, offering advanced high strength steel with brilliant net lightweighting impact designed to achieve both enjoyable and affordable transportation from point A to point B.

NanoSteel Advanced High Strength Steel

According to the Corporate Average Fuel Economy (CAFE) regulations, improved fuel efficiency is an essential feature in future light trucks and other automobiles in the United States every year through 2025. The miles per gallon (MPG) standard is gradually increasing at a rate of 3.5% per year averaged for light trucks and 5% per year for all automobile models, leading to a vehicle average of 54.5 MPG by 2025.

Reducing the overall vehicle weight is one of the key strategies for automakers to achieve higher MPG targets as it helps to increase fuel economy by lowering the energy consumption to operate the car. For this purpose, the Body-In-White system is the key focal point for automotive manufacturers looking for fuel economy due to its weight reduction potential, impact on overall weight reduction for other sub-systems, such as the powertrain, and importance to crash safety.

Structural lightweighting is another key approach for automakers as it helps address fuel efficiency standards without any significant ‘decontenting’ of the vehicle or a necessity to convince users to downsize.

To fulfill the lightweighting goals of the automotive industry, manufacturers have requested new steel materials that provide more options to automotive engineers. These steels must exhibit high strength to enable the design of thinner components and high formability to optimize geometries without compromising vehicle stiffness and safety.

NanoSteel has designed a new class of AHSS to meet these requirements. The company’s AHSS is stronger than its predecessors, enabling automotive manufacturers to use thinner gages of steel to lower the weight of components.

It also has high formability, and as a result, innovative part geometries capable of maintaining superior ride quality and safety can be designed. In addition to these superior properties, AHSS can also be formed into components at room temperature using existing manufacturing infrastructure.

By offering high strength, high ductility steel materials, NanoSteel provides automakers with another reason to use steel as their material of choice for the realization of better fuel economy.

NanoSteel’s AHSS for vehicle lightweighting is further explained in the following video:

NanoSteel Redefining Steel for the Auto Industry

This information has been sourced, reviewed and adapted from materials provided by The NanoSteel® Company.

For more information on this source, please visit The NanoSteel® Company.