Image Credit: gyn9037/Shutterstock.com

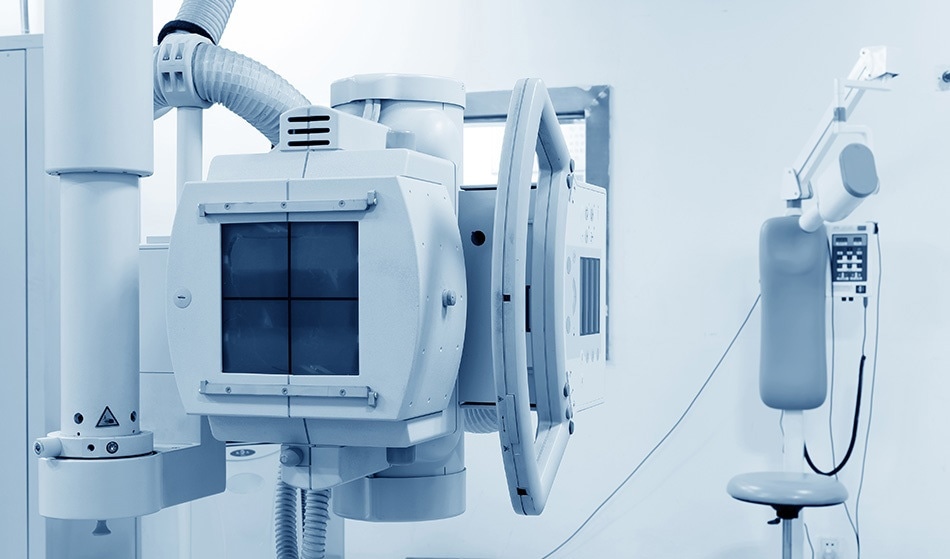

In the case of a medical emergency, one of the most important tools that a physician will utilize to make an accurate diagnosis is a medical diagnostic imaging tool, such as x-ray, computed tomography (CT), magnetic resonance imaging (MRI) or positron emitting tomography (PET) devices.

While these diagnostic imaging tools are extremely useful in providing physicians with a complete anatomical and physiological understanding of the medical situation at hand, they are somewhat limited in their accessibility as these devices are often extremely large and must, therefore, remain at one location within a hospital.

As researchers continue to examine new ways in which they can reduce the size while simultaneously improving the resolution of medical imaging devices, Morgan Advanced Solutions has recently introduced their charge dissipative (CD) coatings that are expected to revolutionize the manufacturing of these devicesl.

Improving Medical Diagnostic Equipment

The purpose of medical diagnostic imaging devices is to provide physicians, and other medical personnel detailed information on not only the anatomical and pathological details of organ systems but have become increasingly specialized to recognize deeper aspects of the physiology, the cellular and molecular biology of tissues of interest. As this market continues to grow, diagnostic equipment manufacturers are becoming increasingly interested in developing imaging equipment that is smaller and lighter in size while also exhibiting greater resolution as compared to current imaging techniques.

Medical Ceramics by Morgan Advanced Materials

Since its introduction into the market in 1856, Morgan Advanced Materials, a London based company, has remained one of the premier global producers of advanced materials used in automotive, defense, electronics, medical, industrial and transport products and components. Within the medical sector, Morgan Advanced Materials offers an extensive range of products including custom ceramic sectors, transducers and piezoelectric materials that can be manipulated for use in a number of different therapeutic equipment types.

These medical equipment components include metalized ceramic RF windows, medical linear accelerator (LINAC) metalized rings, feedthroughs for X-ray tubes used in positron emitting tomography (PET) scanners, computed tomography (CT) scanners and magnetic resonance imaging (MRI) technology and high power insulators for cyclotrons.

Morgan Advanced Materials has also spent a considerable amount of resources on perfecting their HIP Vitox ® product, which is a type of ceramic material derived from high-quality alumina that is capable of withstanding high shock without fracture, hardness and scratch resistance, therefore allowing this material to be particularly useful for hip joint replacement materials.

Morgan’s Charge Dissipative (CD) Coating for Ceramic Parts

In their most recent endeavor, Morgan Advanced Materials has announced their newly developed charge dissipative (CD) coating. Morgan’s CD coating exhibits tailor-made Specific Surface Resistance (SSR), which provides a major benefit for ceramic parts that require high voltages for operation.

As the interest in developing higher resolution and more compact medical diagnostic imaging equipment continues to rise, Morgan plans to supply multiple coated samples to manufacturers, with each sample coated with varying SSR. These coatings, which are composed of a blend of titanium and chromium oxides, provide unique semi-conducting layers to the ceramic product while simultaneously reducing the emission of secondary electrons that can occur in equipment that require X-ray sources to function.

The CD coatings developed by Morgan’s Technical Ceramics business offers manufacturers the ability to design their systems according to the specific SSR and charge dissipation needs. Morgan anticipates that these new materials will allow for new growth within the medical diagnostic equipment field, as these coatings will support more compact, efficient and patient-friendly medical systems.

References and Further Reading

- “New CD Coating Enables Medical Equipment Manufacturers to Operate at Higher Voltages at a Reduced Size” – Morgan Advanced Materials

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.