We all like to treat ourselves, be it to a deliciously soft, fluffy sponge cake, a chewy caramel slice or a crusty croissant. Today, even the more health conscious consumer can choose from and enjoy a wide range of baked products. As palates and tastes have evolved, so too has the range of products on offer, and today the bakery market is as diverse as it is competitive.

However, one thing that has remained constant is the consumer’s desire for quality. The essence of quality does not just relate to flavor and taste but is also about texture. It is therefore essential that manufacturers invest in thorough physical product testing during the earlier stages of development and production to ensure efficiency, optimized recipes and most importantly, consumer satisfaction.

Information about the product’s textural properties can be obtained by texture analysis testing using a TA.XTplus/TA.HDplus Texture Analyser. Texture Analysis can play a pivotal role in measuring consistency in quality control, comparing textural features of competitor products as well as analyzing and controlling the desired textural features of any new or existing product for the market.

Typical Texture Analysis tests for bakery products:

How to Measure Powdered Ingredient Flowability

Many of the base ingredients of baked goods are provided to manufacturers in the form of powdered grains and flours that can be mixed easily and give them a longer shelf life. To maintain quality, a Powder Flow Analyser can be attached to a Texture Analyser and can then be used to measure properties such as powder flow, cohesion and caking. These characteristics are critical to smooth processing and are influenced by factors such as particle size and shape, moisture content, humidity and surface friction. Powder flow analysis enables manufacturers to predict powder behavior and to optimize their processes accordingly, for example, to avoid blockages and inconsistent dosing.

Caption: A Powder Flow Analyser is mounted on a Texture Analyser to measure flowability

The formulation of dough is unanimously the prime determinant of the physical and behavioral traits of a finished baked confectionery product. Many of the textural properties of bakery products depend on the earliest steps of the dough making process – notably the interactions between the main ingredients of flour, water, yeast and oxygen from the air, and by the time the dough has been mixed, its rheological characteristics are already determined. The application of texture analysis at this stage can help guarantee the ideal dough recipe and texture, minimizing any potential financial and material losses to the manufacturer.

How to Measure Dough Extensibility

Resistance to extension and extensibility are important indicators of bread dough quality and its viscoelastic qualities are critical. Dough that is too difficult to manipulate will often result in a misshapen end product and, similarly, dough that is too viscous will not hold the desired structure. Assessment of these characteristics will give a good guide as to how the dough will react during the baking process.

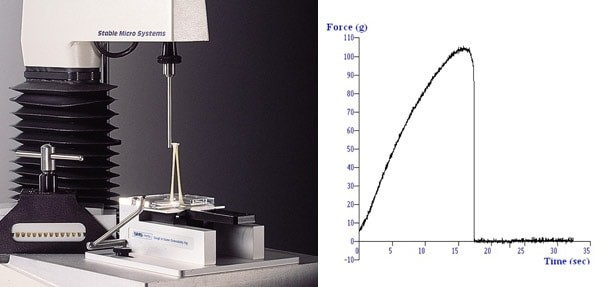

A Dough Extensibility Rig can be used at this stage to measure the extensibility of dough and gluten. Parallel tests of dough and gluten can reveal particular characteristics arising from homogenization, long relaxation times or from adding oxidants, salts, emulsifiers or enzymes. The maximum ‘resistance to extension’ and the extensibility or ‘the distance to break’ are measured and recorded.

Caption: A dough extensibility test on a TA.XTplus texture analyzer and a typical graph

How to Measure Dough Stickiness

Another important predictor of the quality of the finished product is the stickiness of the dough, which is notorious for causing time delays and wastage when not properly controlled. This can be caused by, for example, enzymatic imbalances, excess water or too much flour. If dough is too sticky, it too can cause clogging and blocking of machinery, and equally, if too dry, the dough will not be formed properly and a desirable structure cannot be achieved. A very delicate balance needs to be achieved in order to bind any layers that would otherwise create large holes, while maintaining a firm product structure.

The Warburtons Dough Stickiness Rig is designed to analyze the stickiness of dough at the mixing, dividing and rounding stage. A flat, circular plate compresses a sample while a loadcell contained in the Texture Analyser’s horizontal arm measures the force required to perform the compression. The force taken to separate the probe from the dough is quantified and recorded, with a high force indicating a sticky dough and a dough with no sticking qualities recording a very low force.

Caption: Warburtons Dough Stickiness System testing a typical dough sample

How to measure Bread Firmness and Springiness

Caption: The Bread ‘V’ Squeeze Rig attaches easily to the TA.XTplus texture analyzer for testing fresh or wrapped loaves

Assuming that all the necessary characteristics have been considered by manufacturers prior to and during the preparation and baking processes, a perfect product should result. However, when considering the consumer, the most important textural assessment is of the finished product. The Bread ‘V’ Squeeze attachment replicates a test carried out by the consumer in everyday life. ‘V’ shaped fingers attached to a Texture Analyser are positioned at an angle to represent a typical squeezing action. These fingers produce a standardized, repeatable version of a consumer’s test for freshness; the less force that is measured, the softer the product is perceived to be, while springiness is determined by the ease with which the product recovers from its squeezing action.

The firmness of bakery products is often a factor that determines the level of consumer enjoyment so textural testing methods must be both accurate and measurable. Bakery products are made in every conceivable shape so meaningful textural comparisons must account for different product geometries and various testing methods are available to test a wide range of products. A simple cylinder probe is usually suitable for the measurement of bakery product firmness so long as the product is larger than the surface area of the sample. A standard method (AACC) for bread firmness is also commonly used employing a 36mm diameter probe.

Caption: Cylinder probes can measure firmness of a variety of baked products.

How to Measure Bakery Product Volume

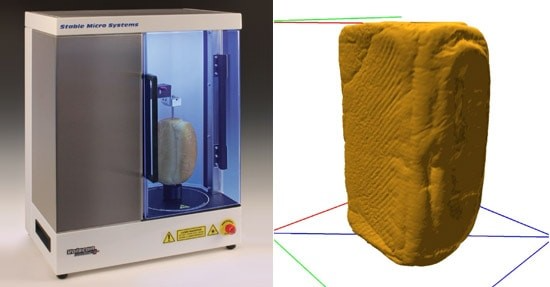

In a similar way to springiness affecting the appeal of a product to the consumer, so too does the volume of a finished product. To ensure optimum desirability, the Volscan Profiler, a laser-based instrument, can accurately measure product volume. With this instrument, bakery manufacturers can control production more rigorously and eliminate volume or weight inconsistencies.

Caption: A Volscan Profiler and a typical product scan

The Volscan Profiler can also be used in the early stages of product development. Manufacturers can subject each batch of flour to test baking to ensure that their ingredients are uniform in terms of their quality. Insufficient volume at the test stage may indicate, for example, an imbalance of enzyme activity or the incorrect quality of the flour chosen for the final product. The results generated can then be used to modify the base mixture helping to save both time and cost.

The Volscan Profiler works by mounting a bakery product at a suitable supporting location, which is then automatically weighed. A laser then measures the contours of the product at given intervals as it rotates. Previous methods have often been time-consuming and unreliable, yet conversely the Volscan Profiler offers manufacturers a non-contact operational assessment, meaning the results can be obtained in less than 60 seconds.

Once the Volscan Profiler has completed its test, product volume, length, width and height measurements are instantly archived. This then automatically calculates the volume yield of the bread. The data can be viewed in 2D or 3D, to allow visual interpretation and comparison of the results. Controlled, repeatable analysis not only provides unambiguous quality assessment standards but also process precision.

There is now more choice than ever and as a result consumers are more discerning than ever. Many different factors come together to create a baked confectionery product that is both appealing and attractive to consumers and texture analysis has a pivotal role. The application of research and science and adopting various textural testing methods enables manufacturers and product development teams to optimize recipes for the consumer market and to streamline processes and procedures.

For a full summary of typical texture analysis tests that can be performed on bakery products:

Bakery Product Texture Measurement & Analysis