In industrial measurement, accuracy is crucial to ensure the integrity of the entire production process. Non-contact scanning is increasingly becoming the preferred method to perform measurements of whole objects in a precise manner quickly. This article discusses blue light three-dimensional (3D) scanners, their working principle, advantages, and limitations, specifically in the context of industrial metrology.

Image Credit: sunlight19/Shutterstock.com

What are Blue Light 3D Scanners?

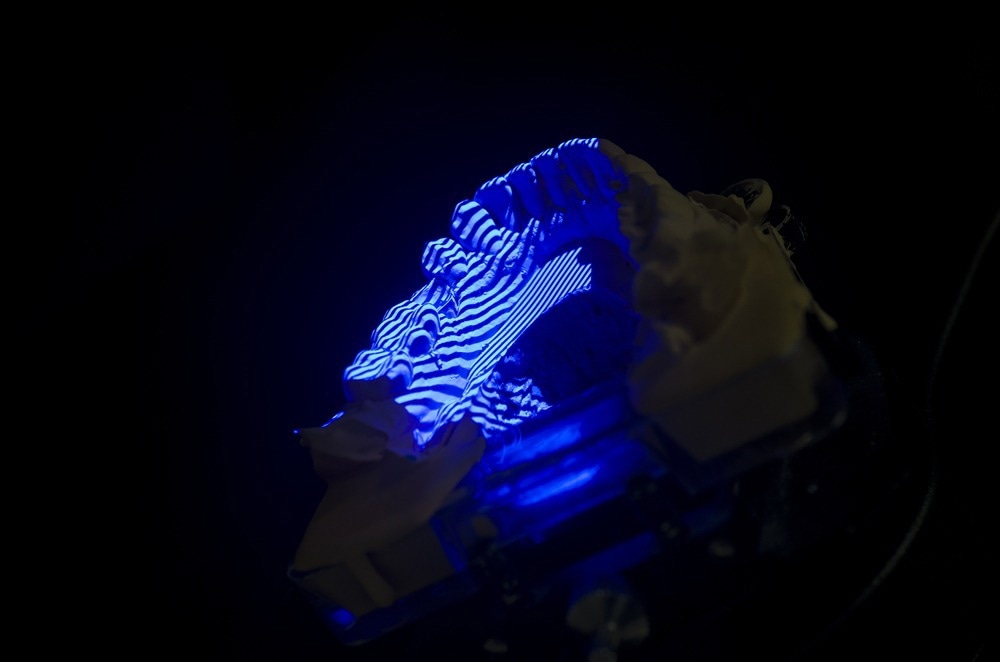

Structured light 3D scanners, typically mounted on a camera stand, robot, or tripod, function as point-and-shoot cameras and need little or no programming with minimal setup. The technology is based on the projection of structured light, which is then captured by high-resolution cameras.

The blue light 3D scanner is primarily based on structured light 3D scanning technology and consists of a camera, projector, and lens system for data collection. These scanners can perform quick surface scans with the finest resolution in the range of a few microns and the highest accuracy.

Working Principle of Blue Light 3D Scanners

A straight line or random pattern of dark and light areas is quickly created by the projector on the surface of the object being measured and the camera captures an image of this overlaid pattern. Every pixel of the image captured is triangulated using the pattern to create a point cloud.

The scanner can capture any distortion or deformation from multiple angles by projecting the grid pattern on the object and then using triangulation to calculate the distance to specific points. Isolated point clouds are aligned, registered, and converted into a texture-wrapped shape file.

The technology calculates the X-Y-Z coordinate points of the entire surface geometry of the object as the pattern shifts from the initial position. Intelligent algorithms align every scan automatically to create a highly accurate, complete 3D model/digital blueprint of the object in a time- and cost-effective manner.

Additionally, the lens system is used to magnify the areas of the object undergoing blue light scanning. The blue light resolution, which is the spacing between the point cloud points, is determined by the specific lenses used on the scanner and the camera size in megapixels.

Very small details can be recreated using the blue light 3D scanner due to the excellent resolution of the blue light. Thus, blue light scanning is considered suitable for highly detailed reverse engineering projects.

Advantages of Blue Light 3D Scanners for Industrial Metrology

The blue light scanning technology is more efficient and effective compared to conventional coordinate measuring machines (CMM) as the technology enables scanning of an entire object within a few seconds in place of making several passes using CMM.

Traditional photogrammetry possesses a low resolution and accuracy compared to blue light scanning. Increased equipment portability, a long-lasting light source, lower temperature influence, and the ability to filter out other light sources during scanning are the major advantages of blue light 3D scanners over white light 3D scanners.

User fatigue is the biggest disadvantage of laser scanners, as users are required to move the devices in paint-like strokes. However, blue light 3D scanners have no such issues as they are mounted on robots or fixed stands.

High-quality blue light 3D scanners can quickly acquire millions of precise 3D data points in a single scan and turn the results into useful visual feedback within the software to substantially optimize the processes.

Image Credit: August Phunitiphat/Shutterstock.com

Sixteen million points can be captured in a single scan with the highest precision using blue light scanning technology, allowing reverse engineering, digitization, and inspection all in one system.

Blue light scanners also measure contours, making them suitable for scanning an entire shape without missing crucial data points. The 3D surface image created by blue light scanning can be rotated, expanded, examined, and stored. Stored images can be used for dimensional inspection.

Moreover, these scanners offer automation possibilities without the maintenance complexity of robots. In a manufacturing process, the automation of 3D blue light scanning can improve productivity significantly.

Blue light scanners are available in different measurement volumes and resolutions for various object sizes and applications, which offer significant flexibility to the users.

Limitations of Blue Light 3D Scanners

Although blue light 3D scanning is suitable for several industrial metrology applications, it can also cause issues/errors in measurements in certain applications. For instance, specular surfaces, such as shiny or highly reflective surfaces, can cause data quality issues.

Additionally, several color ranges, such as the red color, can cause errors in final measurements. These issues can be addressed by applying water-soluble/powder paint on the object to make a diffuse surface.

Error stacking can occur when the object is substantially larger compared to the 3D volume of one single scan. This issue can be resolved by sizing the lens volume properly and cross-checking the measurement using other 3D scanning technologies.

Applications of Blue Light 3D Scanners

The use of blue light 3D scanning is advantageous in the fields of prototyping, manufacturing, quality assurance, and reverse engineering. Blue light scanner technology is more suitable in commercial applications compared to other technologies as it enables precise and rapid high-quality 3D scanning workflows that can be scaled and automated based on demand.

For instance, the United States (US) Army’s Aviation Missile Research, Development, and Engineering Center (AMRDEC) has adopted the ATOS blue light 3D scanners as a standard for its reverse engineering, adaptive machining, and inspection applications. The center saved almost $100 million in costs on a single project by rapidly providing as-built computer models from the data generated from the 3D scan.

Recent Developments

In a recent study published in the Journal of Industrial Integration and Management, researchers redesigned the outer body of an existing car and developed a prototype with futuristic aesthetics, improving aerodynamics using the additive manufacturing (AM) method. The Projet 3D printer and Steinbichler 3D Scanner based on a novel structured blue light-emitting diode lighting 3D scanning technology used in the AM process reduced the cost and time and simplified the redesign and development process of the car.

Revopoint, a leading 3D scanning technology player, has recently introduced its latest blue light 3D scanner based on ultra-precise structured blue light technology with an exceptional accuracy of up to 0.02mm and increased detail for high-resolution 3D modeling.

To summarize, the blue light 3D scanner technology is playing a critical role in industrial metrology applications and can facilitate the modernization of the manufacturing process in the future.

More from AZoM: The Current State of the Global Automotive Manufacturing Market

References and Further Reading

Khanam, T., Goyal, A., Javaid, M., Haleem. (2022). Redesign of Car Body by Reverse Engineering Technique using Steinbichler 3D Scanner and Projet 3D Printer. Journal of Industrial Integration and Management, 07, 02, 171-182. https://doi.org/10.1142/S2424862220500074

Light scanning [Online] Available at https://www.floridamuseum.ufl.edu/digital-lab/resources/light-scanner/

Gout, J. (2017) Taking precision blue light 3D scanning to the next level [Online] Available at https://www.sme.org/technologies/articles/2017/may/taking-precision-blue-light-3d-scanning-to-the-next-level/

Structured-light 3D scanner [Online] Available at https://www.opensourceimaging.org/project/structured-light-3d-scanner/

Newsfile Corp. (2022). Newsfile corp.: Revopoint MINI announces launch of consumer-friendly blue light 3D scanner with incomparable accuracy of 0.02mm. Chatham: Newstex. Retrieved from https://www.proquest.com/blogs-podcasts-websites/newsfile-corp-revopoint-mini-announces-launch/docview/2647481294/se-2

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.