Thin film electronics on flexible substrates is a rapidly evolving technology that has the potential to revolutionize various industries, including healthcare, consumer electronics, and aerospace. This article will explore the advantages, applications, and recent developments of thin film electronics on flexible substrates.

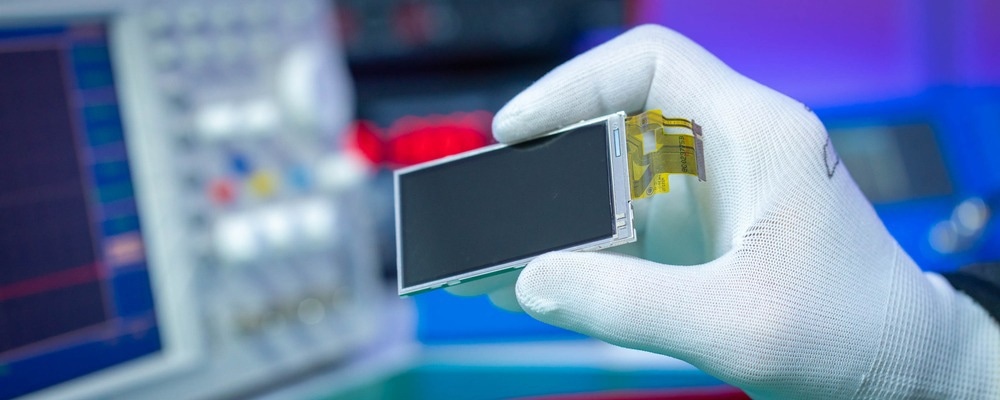

Image Credit: luchschenF/Shutterstock.com

Thin film electronics on flexible substrates refer to the use of thin films of electronic materials, such as semiconductors and conductors, on flexible substrates, such as plastics and polymers. This technology enables the creation of flexible and lightweight electronic devices that can conform to various shapes and surfaces.

Advantages of Thin Film Electronics on Flexible Substrates

Thin film electronics on flexible substrates offer numerous advantages compared to traditional electronics. These include flexibility, allowing for adaptable devices that conform to diverse shapes and surfaces, making them ideal for aerospace and wearable applications in addition to their lightweight nature.

These electronics consume less power than their conventional counterparts, making them well-suited for battery-powered devices. Moreover, their cost-effectiveness is notable as they can be manufactured using affordable methods like roll-to-roll printing, ultimately reducing production expenses.

Applications of Thin Film Electronics on Flexible Substrates

Thin film electronics has been the source of remarkable developments in the field of electronics, unlocking a diverse range of exciting new applications. Some of these include the following;

Wearable Health Monitors: These flexible sensors can seamlessly integrate into clothing or adhere directly to the skin, providing continuous tracking of vital signs like heart rate, body temperature, and early disease indicators.

This non-invasive approach has the potential to revolutionize personal healthcare, with companies like Fitbit and Apple already incorporating thin film electronics into their wearable devices for lightweight and comfortable fitness and health tracking. Also, recently, smart bandages that can monitor wound healing and deliver drugs to the wound site using thin-film electronics on a flexible substrate are attracting a lot of interest.

Foldable and Rollable Displays: The advent of foldable smartphones and rollable displays has been made possible through thin film electronics. OLED (organic light-emitting diode) technology, coupled with flexible substrates, allows manufacturers to create screens that can be folded, rolled, or even bent without compromising image quality. Samsung has developed a flexible OLED display using thin film electronics on a flexible substrate, enabling the creation of foldable smartphones and tablets.

Smart Packaging: Thin film electronics are also making their mark in the packaging industry. Smart packaging with integrated sensors can provide real-time information about the freshness and condition of perishable goods. This not only reduces food wastage but also enhances consumer safety by ensuring the products are safe to consume.

Energy Harvesting: Here, thin film electronics on flexible substrates can be integrated into clothing or accessories to capture and store energy from body movements or ambient light, powering small electronic devices and reducing the need for conventional batteries.

Biomedical Implants: In the field of medicine, these implants can conform to the body's shape and movement, allowing for more comfortable and effective monitoring and treatment. For instance, flexible brain implants could revolutionize neurology by providing more accurate data and reducing the risk of tissue damage.

Environmental Monitoring: Thin film sensors on flexible substrates are being used for environmental monitoring, including air quality measurement and pollution detection. These sensors can be easily deployed in various locations and provide real-time data to help monitor and mitigate environmental hazards.

Internet of Things (IoT): The IoT landscape is benefiting from the advancements in thin film electronics. Flexible sensors and electronic components can be seamlessly integrated into everyday objects, enabling them to collect and transmit data to the cloud. This connectivity is the foundation of a smarter and more interconnected world.

Recent Developments in Thin Film Electronics on Flexible Substrates

Recent developments in thin film electronics on flexible substrates have shown promising advancements. Nanocomposite films made from cellulose nanofibers and ZnS nanoparticles have been successfully prepared, demonstrating the potential for integration into high-frequency electronics.

Additive printing techniques have been explored for realizing stack-structured thin-film transistors (TFTs) on flexible substrates using various functional materials such as silicon, organics, and inorganics. Self-powered flexible temperature-pressure bimodal sensors have been developed using thermoelectric films and conductive elastic materials, enabling precise sensing of temperature and detection of external tactile stimulus.

Transparent-flexible thermoelectric materials, such as Ti-doped ZnO thin films, have been grown on polyimide substrates, demonstrating enhanced thermoelectric properties for future small-sized consumer electronics and wearable devices.

Van der Waals epitaxy has been utilized for the growth of CdSe thin films on mica substrates, enabling the transfer of these films to other substrates for flexible photodetectors with excellent device performance. These recent developments highlight the progress in thin film electronics on flexible substrates, paving the way for advancements in wearable electronics, robotics, and consumer devices.

Some areas in which we look forward to seeing more developments include stretchable electronics, biodegradable electronics, and 3D printing.

While the progress in thin film electronics on flexible substrates is undeniably impressive, there are still challenges that need to be addressed for the technology to reach its full potential.

One of the key challenges is maintaining performance and stability over time, especially as the flexible substrates endure repeated bending, stretching, and other mechanical stresses. As such, the research focus here is to explore new materials and engineering techniques to enhance the durability of thin film devices.

Conclusion

The rapid progress in thin film electronics on flexible substrates is ushering in a new era of electronics that is characterized by flexibility, adaptability, and integration into various aspects of our lives.

The developments in this field are propelling us closer to a future where wearable health monitors, foldable displays, smart packaging, and more become commonplace. With each breakthrough, the barriers of what was once thought possible in electronics are being shattered, opening doors to endless opportunities for innovation.

As researchers, engineers, and visionaries continue to push the boundaries, we can expect thin-film electronics on flexible substrates to play a pivotal role in shaping the technological landscape of tomorrow.

More from AZoM: How Can Graphene Improve Flexible Electronics?

References and Further Reading

Abdel-karim, A.M., Salama, A.H., Hassan, M.L. (2022). High dielectric flexible thin films based on cellulose nanofibers and zinc sulfide nanoparticles. Materials Science and Engineering: B 276, 115538. https://doi.org/10.1016/j.mseb.2021.115538

Bazinet, R. (2022). Micro 3D Printing – The Ultimate Guide [Online]. All3DP Pro. URL https://all3dp.com/1/micro-3d-printing-guide/ (accessed 8.14.23).

Makenica, (2023). Microscale 3D Printing: Miniature Solution for Big Challenge [Online]. Makenica. URL https://makenica.com/microscale-3d-printing/ (accessed 8.14.23).

Network, M.C. (2022). What is microscale 3D printing? Lessons learned from Mayo Clinic [Online]. Medical Design and Outsourcing. URL https://www.medicaldesignandoutsourcing.com/what-is-microscale-3d-printing-mayo-clinic-microfabrication-lab/ (accessed 8.14.23).

O’Neill, B. (2022). Micro 3D printers and micro AM [Online]. Aniwaa. URL https://www.aniwaa.com/buyers-guide/3d-printers/micro-3d-printers-micro-am/ (accessed 8.14.23).

Pan, W., Liu, J., Zhang, Z., Gu, R., Suvorova, A., Gain, S., Wang, H., Li, Z., Fu, L., Faraone, L., Lei, W, (2022). Large area van der Waals epitaxy of II–VI CdSe thin films for flexible optoelectronics and full-color imaging. Nano Res. 15, 368–376. https://doi.org/10.1007/s12274-021-3485-x

Pang, Q., Yang, F., Jiang, Z., Wu, K., Hou, R., Zhu, Y. (2023). Smart wound dressing for advanced wound management: Real-time monitoring and on-demand treatment. Materials & Design 229, 111917. https://doi.org/10.1016/j.matdes.2023.111917

Park, Y.-G., Yun, I., Chung, W.G., Park, W., Lee, D.H., Park, J.-U. (2022). High-Resolution 3D Printing for Electronics. Advanced Science 9, 2104623. https://doi.org/10.1002/advs.202104623

S, C, (2023). The Best Micro 3D Printing Solutions On the Market [Online]. 3Dnatives. URL https://www.3dnatives.com/en/the-best-micro-3d-printing-solutions-19012023/ (accessed 8.14.23).

Tong, C. (2022). Printed Flexible Thin-Film Transistors, in: Tong, C. (Ed.), Advanced Materials for Printed Flexible Electronics, Springer Series in Materials Science. Springer International Publishing, Cham, pp. 257–345. https://doi.org/10.1007/978-3-030-79804-8_6

Truong, D.C., Thaowonkaew, S., Muthitamongkol, P., Horprathum, M., Kumar, M., Le, T.B.N., Pham, A.T.T., Seetawan, T., Vora-ud, A., Phan, T.B. (2022). Relaxation of residual stress-controlled thermopower factor in transparent-flexible Ti-doped ZnO thin films. Ceramics International 48, 2605–2613. https://doi.org/10.1016/j.ceramint.2021.10.043

Wang, Y., Zhu, W., Deng, Y., Zhu, P., Yu, Y., Hu, S., Zhang, R. (2022). High-sensitivity self-powered temperature/pressure sensor based on flexible Bi-Te thermoelectric film and porous microconed elastomer. Journal of Materials Science & Technology 103, 1–7. https://doi.org/10.1016/j.jmst.2021.07.008

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.