Hitachi has introduced a high performance TripleBeam™ FIB-SEM—called NX5000—that enables excellent TEM lamella preparation and provides accurate cross-sectioning and 3D volume microscopy.

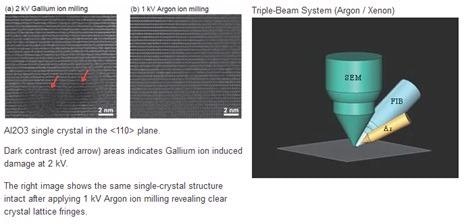

The built-in Ar+/Xe+ beam helps prepare uniform, ultra-thin, low damage TEM lamellae easily, even on the most complex materials.

Gentle, High-Precision Lamellae Finishing

- Multi-directional milling eliminates curtaining

- Flatter, thinner, wider and low damage lamellae can be made using the built-in Ar+/Xe+ broad beam

- Ga+-induced damage is prevented

Image Credit: Hitachi High-Tech Europe

High Performance Imaging

- Offers sub-nanometer resolution even at low kV

- Fine structures can be clearly observed with the high performance, dual-mode SEM (field-free or immersion)

- Users can get their required contrast at any time with the multi-mode STEM and the sensitive in-lens detectors

High Performance Ga+ Milling

- Rapid FIB/SEM switching (Timesharing mode) allows live fabrication and observation with complete clarity

- High throughput with beam currents of more than 100 nA

Unique Sample Handling Solutions

- Specimens with up to 150 mm diameter can be rapidly exchanged via the load lock

- Lamellae can be directly transferred to TEM under vacuum, using the built-in side entry rod holder

- Double-tilt sub-stage provides more degrees of freedom for excellent milling geometry

Advanced Automation

- The simple recipe creator automates lamella preparation, imaging, cross-section generation, etc.

- Complex samples can be rapidly navigated with the CAD navigation system

- Up to 20 TEM lamellae can be lifted out automatically