The ContourX-500 Optical Profilometer from Bruker Life Sciences Mass Spectrometry is the world’s most extensive automated benchtop system for rapid and non-contact 3D surface metrology. The gage-capable ContourX-500 sports unparalleled Z-axis resolution and precision and offers all of the industry-recognized benefits of Bruker’s white light interferometry (WLI) floor-standing models in a compact footprint.

The profiler is easily tailored for an extensive range of complex applications, from QA/QC metrology of precision machined surfaces and semiconductor processes to R&D characterization for ophthalmics and MEMS devices.

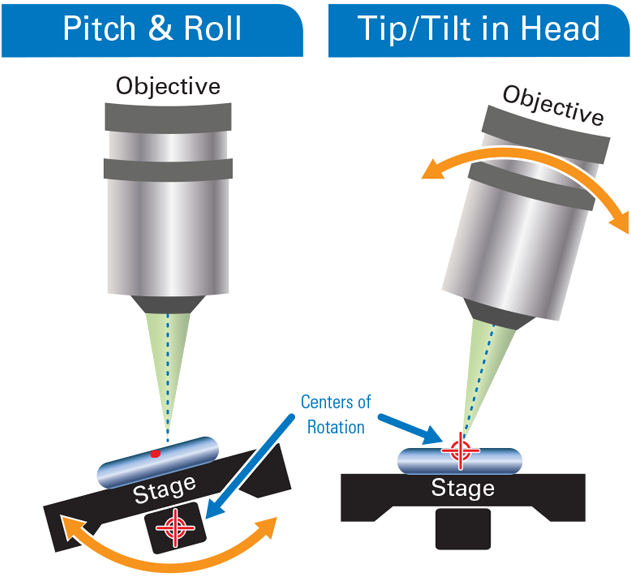

Tip/Tilt Optical Head

Quantifies surface features over a range of angles while minimizing tracking errors.

Integrated Air Isolation

Offers the best metrology accuracy in a space-efficient footprint.

Most Advanced User Interface

Offers intuitive access to a wide library of pre-programmed filters and analyses.

Features

Designed for Unmatched Benchtop Metrology

Bruker’s proprietary tip/tilt in the head offers unrivaled user flexibility for production setup and inspection. By coupling the auto tip/tilt operation with the optical path in the microscope head, Bruker has coupled the inspection point to the line of sight independent of tilt.

This leads to less operator intervention offering the utmost reproducibility. Other hardware features include a ground-breaking stage design for greater stitching abilities and a 5MP camera with a 1200 x 1000 measurement array for larger field-of-view, lower noise and greater lateral resolution.

The combination of such features with automated staging and objectives makes the ContourX-500 perfectly suited to “measure-on-demand” R&D and industrial metrology — all within a small footprint.

Traditional pitch-and-roll stage designs require operator adjustment of five axes of motion to maintain point of inspection on line of sight for measurement. The unique Bruker tip/tilt in the head design maintains the line of sight on the point of inspection —regardless of tilt —resulting in optimized image acquisition and fastest time to data. Image Credit: Bruker Life Sciences Mass Spectrometry

Streamlined Access to Extensive Analysis

Having thousands of tailored analyses and Bruker’s user-friendly, yet strong VisionXpress™ and Vision64® user interfaces, the ContourX-500 is improved for productivity in the laboratory and on the factory floor.

New Universal Scanning Interferometry (USI) measurement mode from Bruker offers the self-sensing surface texture, completely automated and improved signal processing while offering the highly accurate and realistic computation of the surface topography that is being examined.

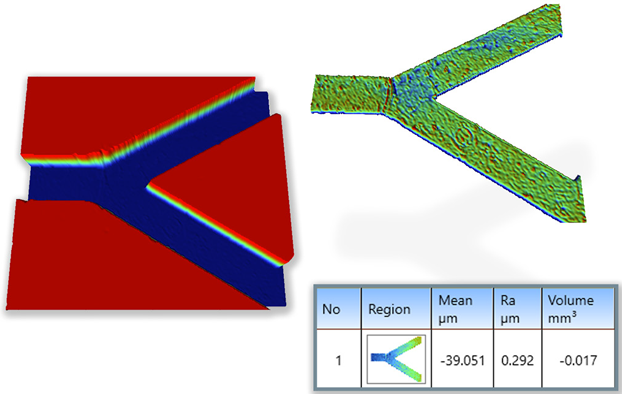

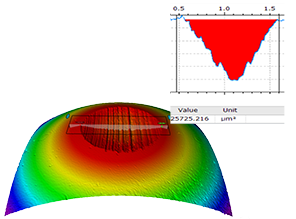

Analysis of the bottom channel of a microfluidic device with direct extraction via Multiple Region from Vision64. Image Credit: Bruker Life Sciences Mass Spectrometry

Applications

Surface-Independent Metrology with Application-Specific Solutions

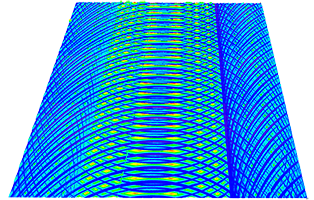

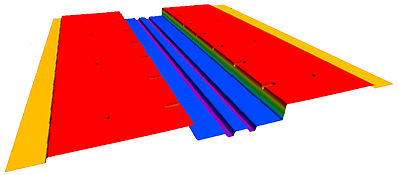

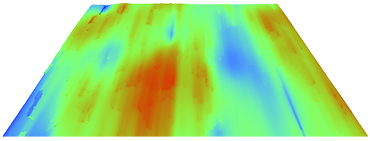

Precision Engineering

Users can retain the surface texture and geometric dimensions of precision-engineered parts inside tight specification limits. The gage-capable measurement systems offer effective feedback and reporting as they monitor, track, and calculate processes and evaluate GD&T conformance.

Image Credit: Bruker Life Sciences Mass Spectrometry

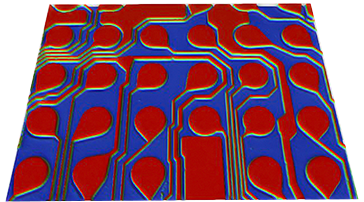

MEMS and Sensors

It is possible for users to execute highly repeatable etch depth, high-throughput, film thickness, step-height, and surface roughness measurements, as well as sophisticated crucial dimension metrology of both MEMS and optical MEMS.

Optical profiling could help characterize devices across the manufacturing process from wafer to final test, and also through transparent packaging.

Image Credit: Bruker Life Sciences Mass Spectrometry

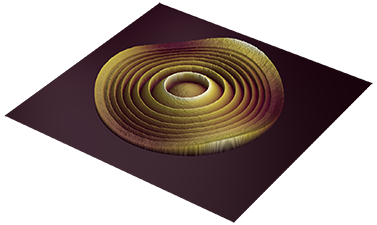

Orthopedics/Ophthalmics

For users, achieving accurate and repeatable measurements of implant materials and components via the complete product life cycle is possible. The WLI optical profilers aid R&D, QA, and QC analyses, for applications varying from the characterization of surface parameters of lens and injection molds to surface finish verification and wear of medical devices.

Image Credit: Bruker Life Sciences Mass Spectrometry

Tribology

Quantify, examine, and regulate the impact of friction, lubrication, wear, and corrosion on material or component performance and lifespans. Identify quantitative wear parameters and perform fast pass or fail inspections on the broadest range of smooth, shiny, or tough surfaces.

Image Credit: Bruker Life Sciences Mass Spectrometry

Semiconductors

Yield can be enhanced and charges can be reduced for both front- and back-end manufacturing processes with non-contact, automated, wafer-scale metrology systems. Execute post-CMP die flatness inspection; coplanarity, bump height, and defect identification and analysis; and quantify the vital dimensions of component structures.

Image Credit: Bruker Life Sciences Mass Spectrometry

Optics

Users can better comprehend the underlying causes of defects and improve polishing and finishing processes with the help of precise and repeatable sub-nm roughness measurements. The non-contact metrology systems allow compliance with highly strict specifications and ISO norms.

This is for samples varying from small aspheric and free-form optics to optical components with complicated geometries, to diffraction gratings and microlenses.

Image Credit: Bruker Life Sciences Mass Spectrometry