Dec 12 2007

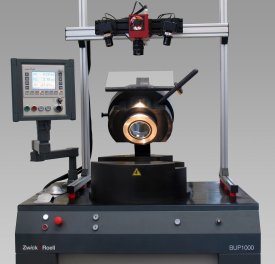

At their October trade fair in Germany this year, Zwick introduced a new testing machine for evaluating the mechanical deformation of sheet metals.

The new hydraulic BUP 1000 machine addresses the latest requirements of the steel industry, especially for use in new automotive applications where higher tensile strength combined with high formability has become more and more important.

New sheet metal testing machine from Zwick for drawing forces up to 1000 kN.

New sheet metal testing machine from Zwick for drawing forces up to 1000 kN.

Forming behavior has to be characterized, both for the modeling of newly developed products, and for quality assurance / production control. The machine can be used to determine the forming limit curve (FLC) and, with drawing forces up to 1000kN and a punch diameter of 100mm, meets the latest requirements of ISO 12004.

Building on Zwick’s global lead in automated test equipment, the system uses digital PLC technology enabling the test to be controlled from either the Force or punch displacement measurement channel. The advantage is that standard tests can be easily carried out, and in addition, the large punch displacement and wide speed range offers a range of useful applications including small scale simulations of the complete forming process.

Data acquisition is under the full control of Zwick’s standard hardware platform testControl electronics whilst data is processed and analyzed, and organized through the testXpert® software.

With its remote control capability of the function display unit, and the hydraulic operation of the tool head aiding the insertion and removal of test specimens, the system offers significant and powerful benefits. It also greatly simplifies the everyday operation.