Jun 6 2008

Teijin Aramid GmbH is using Freeman Technology’s FT4 Powder Rheometer to deliver essential information in the development of new friction materials.

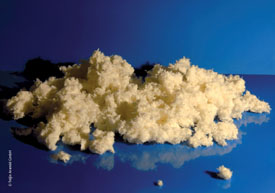

Teijin Aramid, one of the leading aramid producers in the world, manufactures among others the para-aramid fibre Twaron. This is a very strong, light and heat-resistant, high performance fibre that is used in a wide range of applications, including friction materials such as brake linings and clutch facings. The FT4 is being used to investigate the flow behaviour of friction materials containing Twaron pulp, with a view to designing formulations with specific properties.

Describing his experience with the FT4, Andreas Wodetzki, Technical Account Manager at Teijin Aramid, said, “Non-asbestos organic friction material formulations include many variable raw materials all of which can affect the overall powder properties. We needed a highly repeatable method for measuring the flow behaviour of such formulations when changing the para-aramid pulp type and content. The FT4 gives us repeatable results that are both intuitive and highly informative.”

Using the FT4, the team at Teijin Aramid has demonstrated that different para-aramid pulp types have an influence on flowability, compressibility and permeability across the powder bed. This knowledge allows the development of friction material formulations having special features. With cost saving being a major issue in the brake industry, standardized testing of friction material formulations should not only enable cost reductions both in development and during production, but also help optimize quality.

According to Andreas Wodezki, “The FT4 is bringing more science to understanding ‘black magic’ friction material formulations. We are continuing to generate data in order to learn from past experience and to better understand the influence of different raw materials.”